Tamper-proof stickers are one of the easiest ways to protect products from theft or misuse. You’ve likely seen them on electronics, medicine boxes, and sealed packaging. But not all security labels work the same. Some stickers may fracture, reveal “VOID” messaging, or embed serial codes to deter tampering.

This guide walks you through the different types of tamper-proof stickers, their real-world applications, and how to choose the best fit for your products in 2025. About finding the one that protects what matters, we’ll cover what to look for and what to avoid!

What Are Tamper-Proof Stickers?

Tamper-proof stickers, also known as security labels, are designed to show clear signs when someone tries to open or move a product. They work by breaking into pieces, leaving behind a “VOID” message, or adhering so strongly that peeling them off damages either the sticker or the product surface.

These labels don’t stop tampering outright. But they make every attempt visible, helping protect your brand and your customers. The tamper technology behind these stickers depends on clever material and adhesive design. They work across many surfaces—glass, plastic, and cardboard. This makes them versatile tools in pharmaceuticals, electronics, food, cosmetics, and more.

The 6 Main Types of Tamper-Proof Stickers

Tamper-proof stickers come in several forms. And the right type depends on how the label needs to work and what kind of protection your product needs. Below are six common types and how each one functions.

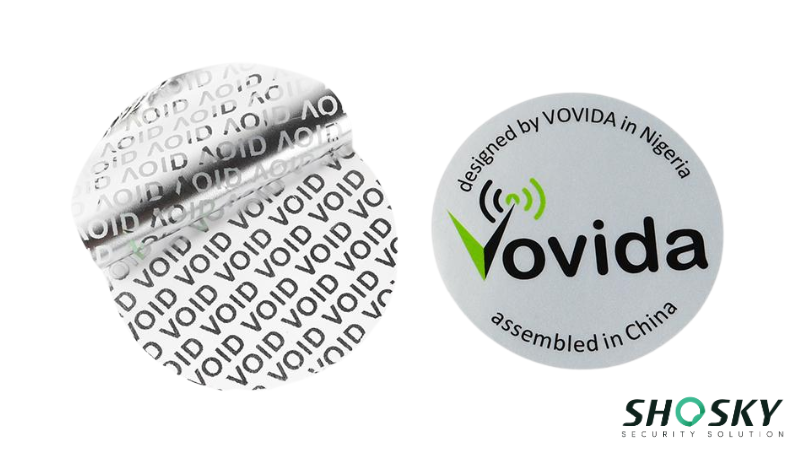

1. Void Labels

Void labels are designed to leave behind a visible message, like “VOID” or a custom pattern, when someone tries to peel them off.

This message appears either on the product surface, the label itself, or both, making any removal attempt obvious. They’re widely used in electronics, logistics, and packaging, where seal integrity is critical. Once removed, the label can’t be reapplied without showing signs of tampering.

These labels rely on a dual-layer construction. When pulled, the top layer separates and exposes the hidden print embedded in the bottom layer or adhesive.

Some versions leave residue, while others are residue-free for clean surfaces. They work well on plastic, metal, and paperboard and are often compliant with packaging regulations in sensitive industries like healthcare.

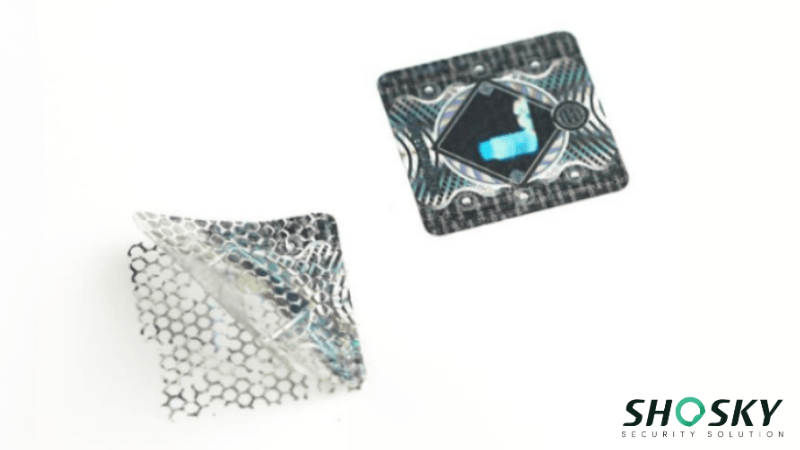

2. Destructible (Eggshell) Labels

Destructible labels, commonly called eggshell stickers, are made from brittle materials that crack and break apart when tampered with. They’re designed so you can’t peel them off in one piece. Instead, the label fractures into small shards, making reapplication impossible and cleanup difficult. These are especially useful in preventing return fraud and warranty abuse.

The label material is ultra-thin and pressure-sensitive, allowing it to conform to uneven or curved surfaces. Once applied, the adhesive cures over time, forming a bond that’s stronger than the label material itself.

Any removal attempt causes the label to tear from multiple points. This makes them ideal for use on electronics, tools, and asset tracking applications where physical evidence of tampering is key.

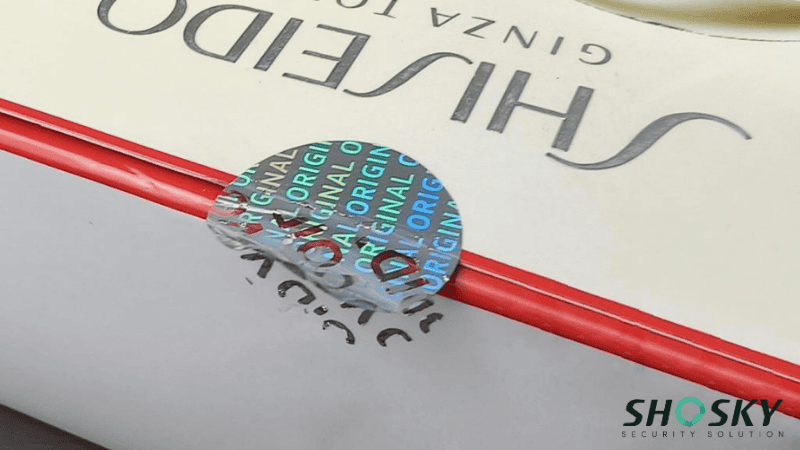

3. Holographic Security Labels

Holographic labels add a layer of visual complexity that’s hard to replicate. They use reflective foil and layered imaging to create a shimmering, multi-angle effect. This makes them highly visible and useful for verifying product authenticity at a glance. Because of their eye-catching look, they’re often used on luxury goods and branded electronics.

Beyond visual appeal, holographic labels can also include tamper-evident features. Some versions break apart or show hidden messages when removed. Others combine holograms with serial numbers, barcodes, or microtext for added verification. This dual purpose—authentication and tamper resistance—makes them a smart choice for high-risk, high-value items.

4. Transparent Seal Labels

Transparent seal labels are commonly placed over box flaps, bottle caps, or product openings. They’re clear and low-profile, which helps preserve packaging design while still offering tamper visibility. If someone opens the package, the label typically tears or wrinkles, making it obvious the item has been accessed. This subtle design works well in retail and cosmetic packaging.

Many transparent labels use special adhesives that leave a mark or destroy the film upon removal. Some are pre-slit or micro-perforated to tear under pressure. Brands often print their logo, batch number, or subtle patterns onto the film for added traceability. These labels are a discreet yet effective solution for preserving product integrity on store shelves.

5. Color-Changing Labels

Color-changing labels react to specific triggers like heat, pressure, or UV light. These changes serve as visual proof that tampering has occurred. For example, a label might shift from white to red if exposed to high temperatures or physical pressure. This type is especially useful for items sensitive to storage conditions or handling.

These labels are often used in pharmaceuticals, food packaging, or tech, where improper handling can impact safety or performance. The technology is built into the ink or adhesive layer. Once triggered, the color change is permanent, signaling that the product may no longer be secure. It’s a simple, effective way to monitor product history without complex systems.

6. QR/Serial-Enabled Labels

QR and serial-enabled labels link physical products to digital tracking systems. Each label carries a unique code that can be scanned to verify origin, shipment details, or warranty status. This adds traceability and helps prevent counterfeiting, especially in online sales and large distribution networks.

These labels can also log scan history, so you can detect suspicious activity, like multiple scans in different locations. Some are paired with mobile apps for quick authentication by customers or inspectors. Combined with tamper-evident features, these smart labels offer both physical and digital security. They’re commonly used in electronics, healthcare, and high-end retail.

Tamper-Proof Sticker Types – At a Glance

Different tamper-proof stickers react in different ways. The right type depends on your product, use case, and how you apply it. Here’s a quick look.

| Type | Tamper Indicator | Common Uses |

|---|---|---|

| Void Sticker | Leaves “VOID” text or pattern | Electronics, logistics |

| Destructible Label | Breaks into pieces when removed | Warranty seals, tools |

| Hologram Sticker | Distorts or breaks on tampering | Luxury goods, tech |

| Clear Seal | Rips or wrinkles when opened | Retail, skincare packs |

| Color-Shift Label | Color changes with pressure/heat | Food, medicine packaging |

| QR/Serial Code | Scan or code confirms authenticity | E-commerce, pharma |

With so many types available, it’s easy to find a tamper-evident solution that fits your product and packaging needs. From visible deterrents to smart tech features, these stickers support both safety and branding, helping your business stay secure without sacrificing design.

How to Choose & Customize the Right Tamper-Proof Sticker?

Before choosing a tamper-proof sticker, think about where and how it will be used. The wrong choice can lead to poor adhesion or weak protection. Here’s what to consider.

Step 1: Define Your Goal (Security Level)

Your first step is to define what “security” means for your product. Are you trying to deter casual theft, prevent warranty fraud, or stop sophisticated counterfeit rings? Each goal requires a different type of sticker.

- Simple Tamper Evidence: If your goal is just to show a customer that a package hasn’t been opened (like a food container or cosmetic box), a simple Transparent Seal or VOID Label is effective.

- Warranty & Asset Protection: If you need to prevent component swapping or fraudulent returns (like on electronics), a Destructible (Eggshell) Label is ideal as it’s impossible to remove cleanly.

- Anti-Counterfeiting & Brand Authentication: If you’re protecting a high-value or luxury item, you need a label that’s difficult to replicate. This is where Holographic Labels or QR/Serial-Enabled Labels are essential, as they prove authenticity.

The right level of security depends on your product’s risk, value, and your specific business goals.

Step 2: Match the Sticker to the Surface & Environment

A sticker’s effectiveness is 100% dependent on its adhesive and material. You must match the label to both the product’s surface and its lifecycle. Here are some aspects you need to pay attention to:

Surface Texture

A label designed for smooth glass or polished plastic will likely fail on a porous, recycled cardboard box. Rough or textured surfaces (like some powder-coated metals) require a thicker, more aggressive adhesive that can fill the gaps.

Surface Energy

Low Surface Energy (LSE) plastics (like polyethylene, used in many bottles) are notoriously difficult to stick to and require a specialized LSE adhesive.

Environmental Conditions

Think about the product’s journey. Before making a decision, consider the following questions:

- Will it sit in a hot warehouse (requires high-heat resistance)?

- Will it be on a frozen food package (requires a cold-temperature adhesive)?

- Will it be exposed to moisture, chemicals, or UV light (requires a durable topcoat and stable adhesive)?

A weak sticker that falls off in transit is worse than no sticker at all, as it can cause false alarms or miss tampering entirely.

Step 3: Verify Industry Compliance Needs

Security is often not just a good idea; it’s the law. Many industries have strict regulations for packaging integrity to protect consumers.

- Pharmaceuticals & Medical: The FDA’s rules on tamper-evident packaging are extremely strict. Labels must be compliant, and many (like those on medical devices) must also adhere to ISO standards for traceability and material safety.

- Food & Beverage: Tamper-evident seals are required on many products to prevent contamination. Materials must be “food safe” if they come into contact with the product.

- Electronics: Compliance might relate to (Restriction of Hazardous Substances), ensuring the label materials themselves are safe.

Some industries require specific label types to meet legal standards. For example, FDA or ISO rules may apply to medical or food items. Make sure your tamper-proof sticker meets these compliance marks. Skipping this step can lead to delays, fines, or product recalls.

Step 4: Define Customization (Branding & Data)

Start with the basics: shape, size, and color. Labels can be shaped for bottles, caps, boxes, or pouches. A good fit helps prevent peeling in transit.

Next is branding. You can add your logo, company pattern, or even a unique design that’s hard to copy. This not only supports product safety but also builds trust with buyers through visible evidence of authenticity.

For products that require track-and-trace control, use serial numbers or variable data. Barcodes, QR codes, and batch info can help you track every item from production to shelf, which is key for industries like pharma and electronics. If you need a higher level of protection, consider smart features. NFC chips, UV ink, and covert messages provide an additional layer of tamper resistance, making them harder to duplicate. These are often used in high-risk sectors or high-value goods.

Step 5: Partner with a Certified Supplier

Finally, your sticker is only as good as the company that makes it. A cheap, low-quality sticker that fails in the field can cost you far more than you saved.

- Look for Experience: Choose a supplier with documented experience in your specific industry (e.g., pharmaceuticals, electronics, logistics). They will already know the right materials, adhesives, and compliance standards.

- Ask for Samples: Always test samples on your actual product and subject them to your real-world environmental stresses (heat, cold, moisture, abrasion).

- Verify Certifications: Ask for proof of compliance. Are they ISO-certified? Can they provide food-safe or medical-grade materials?

A good partner (like Shosky) acts as a consultant, helping you navigate the previous four steps to avoid poor adhesive quality, printing errors, or compliance failures that could risk your operations and brand image.

Industries & Use Cases for Tamper-Proof Stickers

Tamper-evident stickers aren’t just about security—they help protect your brand and reduce risks that come with shipping, retail, or online sales. Companies across industries use them to build buyer trust and limit losses from fraud or contamination.

1. Electronics & E-commerce (Warranty Protection)

Labels are widely deployed for warranty protection and fraud prevention in high-value items; electronics account for roughly 12 % of tamper‑proof label usage, including destructible and holographic versions.

Case Study: Amazon Renewed uses breakable seals on refurbished electronics to reduce warranty scams. If a customer tries to tamper with the product, the label leaves a clear mark, protecting Amazon from false claims.

2. Pharmaceuticals & Healthcare (Compliance & Safety)

Over 85 % of pharmaceutical manufacturers have adopted advanced security labels—like serialized, tamper‑evident, and induction-seal labels—to fight counterfeit drugs and meet FDA/EMA regulations.

Case study: Medtronic (medical devices) uses serial void stickers on packaging to support traceability and compliance during transportation and storage. These tamper-resistant seals offer visible evidence if the packaging is disturbed.

3. Food & Beverage (Consumer Safety)

Leading companies now use tamper‑evident labels—shrink bands, induction seals—on approximately 70 % of packaging globally to prevent contamination and food fraud.

Case study: Nestlé rolled out tamper-evident caps and neckband seals on bottled drinks and baby formula. These seals show if a package was opened before sale, helping improve shelf trust.

4. Cosmetics & Skincare (Brand Authenticity)

The beauty sector favors discreet, branded tamper-proof seals—such as transparent or holographic types—driven by consumer demand for visible authenticity and shelf safety.

Case Study: L’Oréal has utilized transparent, branded box seals to combat in-store tampering and ensure product hygiene for high-end skincare. These small, clear labels seal the outer carton flaps. Customers can see the seal is intact, reassuring them that no one has opened the jar to test or contaminate the product.

5. Apparel & Retail (Loss Prevention)

Security labels are used to block fake goods, track batches, and reassure buyers—especially in resale markets—helping verify authenticity across supply chains.

Case study: Online retailer ASOS has implemented specialized return tags to tackle the costly problem of “wardrobing” (customers wearing an item and then returning it). These are often large, conspicuously-placed “Do Not Remove” security labels. The tag is designed to be highly visible when worn and is attached in a way that it must be broken or removed to wear the garment properly. If a customer returns the item with the tag broken or missing, the company can enforce its return policy and reject the refund, saving millions in return fraud.

FAQs

Q1: Are tamper-evident stickers reusable?

No, once removed or tampered with, they can’t be reused or reapplied.

Q2: Can I apply stickers manually, or do I need a labeling machine?

You can apply them by hand. Machines help with speed and consistency for bulk use.

Q3: Can small businesses afford custom tamper-resistant stickers?

Yes, many suppliers offer budget-friendly custom options in small batches.

Conclusion

Tamper-evident stickers play a key role in protecting your products, brand, and customers. From reducing fraud to building shelf trust, the benefits are clear. And with so many custom options available, it’s easy to select the right type for your operations. Just make sure to work with certified suppliers who understand your needs and are committed to product safety!

Protect Your Products with Shosky’s Tamper-Proof Stickers

Shosky Security offers tamper-proof sticker solutions for every packaging type. Whether you’re in food, tech, or healthcare, our custom stickers help you stay compliant, stop tampering, and protect your brand. Contact us today and get a quote that fits your needs!