In today’s market, consumer trust is invaluable, built upon the assurance of product safety and authenticity. With global supply chains becoming increasingly complex and threats like counterfeiting and product tampering on the rise, businesses face immense pressure to protect their goods and, by extension, their brand’s integrity.

This comprehensive guide delves into the world of tamper-evident packaging materials, exploring their vital role in securing products, enhancing brand reputation, and ensuring unparalleled peace of mind for both companies and consumers.

What are Tamper-Evident Packaging Materials?

Tamper-evident packaging materials refer to any packaging design or device that clearly indicates whether a product has been opened, accessed, or otherwise interfered with after it was sealed.

Its core purpose is not to make tampering impossible (a concept known as “tamper-proof,” which is nearly unachievable), but rather to provide undeniable, visible evidence of any unauthorized attempts to access the contents.

The fundamental principle behind tamper-evident packaging lies in its ability to exhibit an irreversible change or damage when disturbed. This can manifest in various ways:

- Visible Messages: Hidden words like “VOID,” “OPENED,” or “SECURITY SEAL” that appear upon removal.

- Material Destruction: The packaging material itself tears, shreds, or breaks apart, making it impossible to reseal without obvious signs.

- Color Changes: Chemical reactions that cause a distinct color shift when exposed to air or certain conditions after tampering.

- Physical Disruption: Features like frangible seals, perforations, or holographic patterns that distort or break irreparably.

The crucial distinction of tamper-evident packaging material shifts the focus from outright prevention to immediate detection, ensuring that both consumers and supply chain handlers can identify compromised integrity at a glance.

In an era of increasing fraud, counterfeiting, and supply chain vulnerabilities, tamper-evident packaging is an essential, proactive measure to safeguard product authenticity, protect brand reputation, and ensure regulatory compliance.

Top 5 Tamper-Evident Packaging Materials

To build and maintain consumer trust, understanding the specific tools at your disposal is key. Different products and industries have unique security needs, making it important to choose the right material for the job. Here are the top 5 most effective tamper-evident packaging materials.

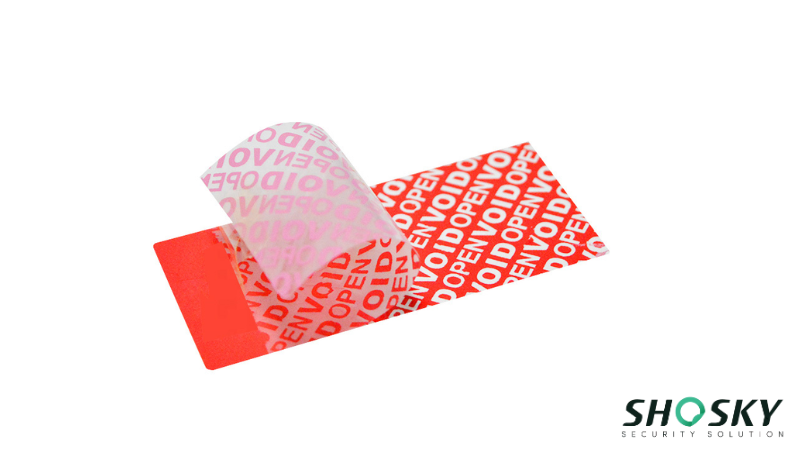

1. Tamper-Evident Tape

Tamper-evident tape, also known as security tape, is a type of adhesive tape designed to reveal clear signs of tampering when applied. If someone tries to interfere with the packaging, the tape will show visible messages such as “VOID” or “OPENED,” indicating unauthorized access to the package.

Types of tamper-evident tapes include:

- Full Transfer Security Tape: This tape leaves a clear, complete mark or message on the surface it was applied to, once tampered with. The full transfer provides strong evidence that tampering has occurred, making it easy to spot when the packaging has been compromised.

- Part Transfer Security Tape: Part transfer security tape leaves a partial residue or message on the surface when removed, while also displaying a message (like “VOID” or “OPENED”) on the tape itself. This offers a dual indication of tampering, providing evidence on both the package and the removed tape.

- Non-Transfer Security Tape: Unlike full transfer tape, this type doesn’t leave any residue on the surface when removed. Instead, non-transfer security tape will show a message such as “VOID” directly on the tape itself, allowing users to detect tampering without leaving marks behind.

Applications: Tamper-evident tape is widely used in shipping and logistics, retail packaging, and security seals on electronic devices. It also plays a crucial role in pharmaceutical packaging and food packaging, ensuring that products reach consumers without any tampering or mishandling during transit.

2. Tamper-Evident Label

Tamper-evident labels, also known as security labels, are specially designed to reveal tampering evidence by either destroying upon removal or exposing a hidden message. These labels are often used for products where security is crucial, like pharmaceuticals and electronics.

Types of tamper-evident labels include:

- Destructible Labels: Ultra-destructible labels break apart when removed, making it impossible to reseal the packaging.

- Void Labels: Void labels display messages such as “VOID” once removed, indicating tampering has occurred.

Applications: Tamper-evident labels are commonly used on pharmaceutical products, health and beauty items, packaged foods, and other retail goods. They provide crucial security, particularly in consumer-facing industries.

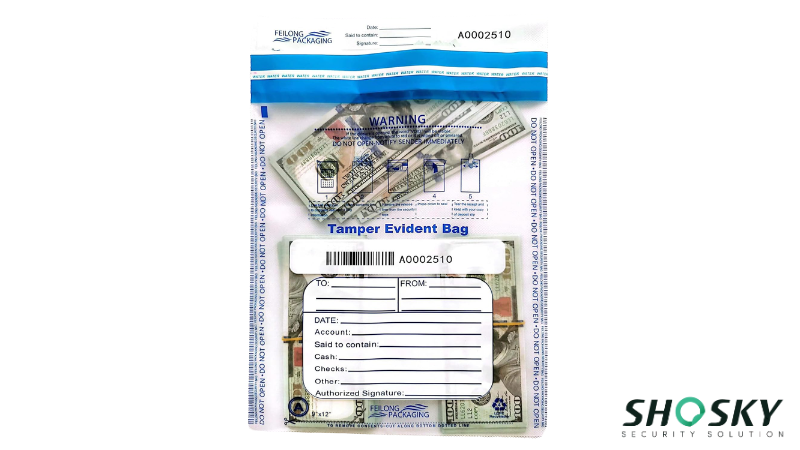

3. Tamper-Evident Bag

Tamper-evident bags are designed to show clear signs of tampering with their contents. These bags typically use adhesive seals or closures that cannot be resealed without leaving visible marks.

Types of tamper-evident bags include:

- Plastic Tamper-Evident Bags: Made from durable polymers like PE or PP, these versatile bags feature secure, adhesive closures that display “VOID” messages or tear upon opening. Ideal for cash, confidential documents, and pharmaceuticals.

- Paper Tamper-Evident Bags: Breathable bags designed for contents needing ventilation, like forensic samples or specific documents. Their strong seals rip or show clear tearing if tampered with.

Applications: These bags are used across industries like food packaging, pharmaceuticals, cash handling, and other high-security applications where safeguarding the contents is a priority.

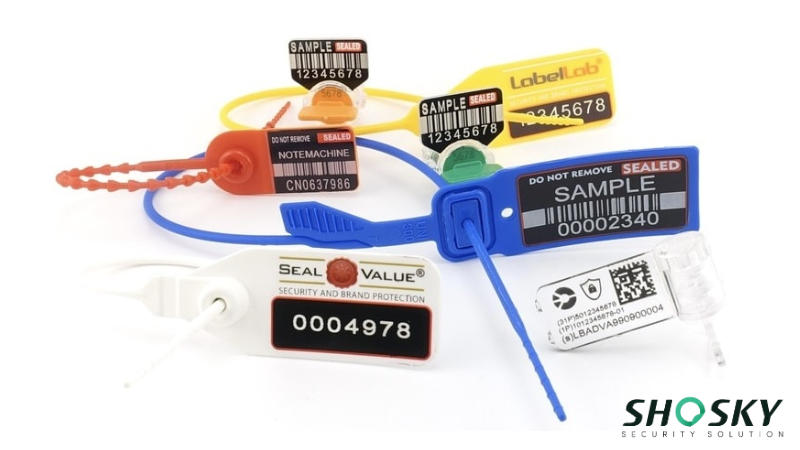

4. Tamper-Evident Seal

Tamper-evident seals are adhesive security seals that leave a distinctive mark or break upon removal, indicating that the package or container has been accessed.

Types of tamper-evident seals include:

- Indicative Plastic Seals: Lightweight, single-use seals that visibly break or distort. Common for bags, meters, and internal doors.

- Bolt Seals: Heavy-duty metal seals for high-security shipping containers, requiring tools for removal.

- Cable Seals: Flexible steel cable seals that must be cut to open, offering high security for various containers.

- Wire Seals: Traditional seals with a wire and crimp, visibly deforming if cut or forced. Used for meters and drums.

- Adhesive Security Seals: Labels that display a “VOID” message or tear destructively upon removal. Ideal for boxes and electronic ports.

Applications: Tamper-evident seals are essential for cargo shipments, government deliveries, medical supplies, high-value items, and pharmaceutical products, providing robust protection during transport and storage.

5. Tamper-Evident Shrink Band

Shrink bands are applied over the caps or closures of bottles, jars, or other containers. When tampered with, the shrink band visibly shows signs of damage or distortion, ensuring the product hasn’t been opened before purchase.

Types of tamper-evident shrink bands include:

- Standard Shrink Bands: Heat-sensitive films that tear irreversibly when removed, showing clear evidence of tampering.

- Perforated Shrink Bands: Designed with tear lines for easy, visible breakage upon opening, indicating tampering while aiding consumer access.

- Holographic Shrink Bands: Feature embedded holograms for enhanced anti-counterfeiting. Hologram distortion signals any attempt at interference.

Applications: Shrink bands are commonly used in the beverage, pharmaceutical, cosmetic, and food products industries. They offer a simple yet effective solution for safeguarding packaged goods and ensuring that products are untouched before reaching the consumer.

Each of these tamper-evident packaging materials offers a unique approach to securing products, but their shared goal is to provide clear, undeniable evidence of interference. Understanding these distinct characteristics is crucial for businesses looking to choose the most effective solution for their specific security needs and to uphold the integrity of their products.

Benefits of Tamper-Evident Packaging Material

Tamper-evident packaging materials play a critical role in enhancing security and ensuring product integrity. By providing clear evidence of tampering, these packaging solutions give customers confidence that the product they are purchasing is safe and untouched. This visibility builds trust, making consumers feel secure in their purchase decisions.

These materials also help businesses comply with industry regulations, such as FDA guidelines for pharmaceuticals and food safety standards. Regulatory bodies often require strict measures to protect consumers, and tamper-evident packaging ensures that companies meet these requirements. This compliance is essential for maintaining a company’s reputation and avoiding legal issues.

Furthermore, tamper-evident packaging prevents fraud and counterfeiting, offering an additional layer of protection for both businesses and consumers. It enhances product integrity throughout the chain of custody, from production to delivery, ensuring that products remain in their original condition and are not compromised in any way.

Examples of Tamper-Evident Packaging in Different Industries

While the principles of tamper-evident packaging remain consistent, their application varies significantly across different sectors, each facing unique security challenges. Let’s explore how these critical packaging methods are implemented in various fields.

Pharmaceuticals: Protect Drugs and Medical Supplies

The pharmaceutical industry faces a significant global threat from counterfeit drugs, estimated by the FDA to comprise approximately 10% of the market, representing over $35 billion USD in annual criminal sales. To combat this, tamper-evident packaging is absolutely crucial, ensuring the safety and efficacy of medications and medical supplies.

The direct link between packaging security and public safety was starkly highlighted by the 1982 Tylenol cyanide tampering case involving Johnson & Johnson. This devastating incident led to federal regulations on tamper-evident packaging for over-the-counter drugs. In response, Johnson & Johnson pioneered a “triple-sealed tamper-resistant packaging” system (glued boxes, plastic neck seals, foil bottle mouth seals), setting a new industry standard.

Today, pharmaceutical products widely use tamper-evident seals, blister packaging, tamper-evident bags, and specialized lidding film. These solutions provide visible evidence of any unauthorized access, safeguarding product integrity throughout the supply chain, and building essential consumer confidence.

Food & Beverage: Ensure Food Safety and Freshness

Maintaining food safety and preventing contamination are paramount in the food and beverage industry, particularly given that approximately 600 million people globally (nearly 1 in 10) fall ill from contaminated food annually, leading to 420,000 deaths. Tamper-evident packaging plays a heavy role here, reassuring consumers of product integrity and freshness.

Commonly used solutions include shrink bands, resealable pouches, and tamper-evident food containers, all designed to provide visible evidence of tampering or breaches in airtight seals. This approach is vital for preventing contamination and protecting consumer safety, especially for products with short shelf lives.

For example, many beverage companies, such as Coca-Cola, utilize shrink bands and tethered caps on their PET bottles. This provides clear tamper evidence, ensuring the bottle hasn’t been opened before purchase, while also enhancing convenience and aiding recycling.

Electronics: Prevent Theft and Product Tampering

In the electronics industry, tamper-evident packaging is vital for preventing theft and product tampering, protecting both retailers and consumers from significant financial losses. The threat from counterfeit consumer electronics is substantial, leading to estimated losses of over $100 billion annually and posing safety risks from unregulated products.

Tamper-evident seals and shrink wrap are frequently used to secure products during transport and storage, providing a clear indication of any unauthorized access. This not only deters theft but also helps maintain product value and prevents the sale of potentially compromised electronics.

For instance, major brands like Apple extensively use discreet, often paper-based, tamper-evident seals on their product boxes (e.g., iPhone packaging). These seals are designed to tear or show disruption if the box has been opened, assuring customers they are receiving a genuine, factory-sealed item.

Retail and Logistics: Safeguard Products During Transport and Storage

Tamper-evident packaging is essential in retail and logistics to safeguard products during transport and storage, minimizing the risk of damage, theft, and tampering across complex supply chains. Organized Retail Crime (ORC) is a massive issue in the United States, representing an estimated $94.5 billion problem, with substantial losses occurring in transit.

A range of tamper-evident packaging solutions, including stretch wrap, shrink film, and tamper-evident tape, are used to protect products from unauthorized access and environmental factors, ensuring they arrive in perfect condition. This enhances supply chain security by allowing for immediate identification of any breaches, facilitating investigations, and preventing the distribution of compromised products.

For example, Amazon FBA (Fulfillment by Amazon) explicitly requires sellers to use secure and tamper-evident packaging for products sent to their fulfillment centers, mandating robust sealing (like poly bags with adhesive closures) to maintain integrity during storage and shipping and prevent “shrinkage.”

Tamper-evident packaging materials’ tailored application across various industries is a testament to their effectiveness in addressing specific threats and ensuring that products reach consumers safely, securely, and authentically.

Choosing the Right Tamper-Evident Packaging Material

Selecting the appropriate tamper-evident packaging material requires careful consideration of several factors. The nature of the product, its shipping conditions, and the associated costs all play crucial roles in making an informed decision. Below is a breakdown of these factors and how to match packaging materials with your specific needs.

| Factor | Details |

|---|---|

| Product Type | Different products require different packaging, e.g., liquids need shrink bands or induction seals, while pharmaceuticals require labels or bags. |

| Shipping Conditions | For long-distance or harsh conditions, use more robust options like tamper-evident tape or seals. |

| Cost | Balance cost with effectiveness. Labels are cost-effective for high-volume products, while shrink bands suit high-value items. |

To match the right tamper-evident packaging to your product, consider both the level of security required and the product’s sensitivity.

For high-value items, such as electronics or pharmaceuticals, tamper-evident seals and bags provide higher security.

For everyday consumer goods like food and beverages, tamper-evident tape or shrink bands may suffice, offering visible evidence of tampering at a lower cost.

Best Practices for Implementing Tamper-Evident Packaging

Implementing tamper-evident packaging effectively starts with selecting the right materials that suit your product’s needs and security requirements. Ensure that all packaging is securely sealed and visibly displays tamper-evident features such as clear VOID messages, destructible labels, or shrink bands.

It’s important to apply these packaging materials consistently and in the correct way to guarantee the integrity of the product. For maximum protection, make sure all packaging components are tightly secured and that tamper-evident features are clearly visible to both customers and transport handlers.

Beyond just the packaging itself, employee training and awareness play a critical role in maintaining security standards. Staff members involved in the packing, handling, and shipping of products should be properly trained to recognize the importance of tamper-evident packaging and ensure it is used correctly.

Employees should also be made aware of the procedures to follow if tampered packaging is discovered. This helps minimize human error and ensures that security standards are consistently met throughout the supply chain. By maintaining a high level of awareness and training, businesses can ensure their tamper-evident packaging provides reliable protection against tampering or fraud.

FAQs

What is the difference between tamper-evident and tamper-proof packaging?

Tamper-evident packaging shows clear signs of tampering, while tamper-proof packaging aims to prevent tampering entirely, though neither offers a 100% guarantee of protection.

What are the costs associated with tamper-evident packaging materials?

Costs vary depending on the material, complexity, and customization of the packaging, but tamper-evident options generally cost more than standard packaging due to the added security features.

What are the FDA tamper-evident requirements?

The FDA requires tamper-evident packaging for over-the-counter drugs and certain food products to ensure consumer safety, with packaging designs that visibly indicate if a product has been tampered with.

Conclusion

In conclusion, tamper-evident packaging materials are essential for ensuring the safety and integrity of products across various industries. With the growing concerns over fraud, counterfeiting, and product integrity, investing in tamper-evident solutions can enhance compliance with industry regulations and improve overall security in the supply chain.

Ensure the Safety of Your Products with Shosky Today!

When it comes to reliable tamper-evident packaging, Shosky Security stands out as a leader in providing high-quality, customizable solutions. We offer a wide range of tamper-evident products, including security seals, bags, tapes, and labels. Contact us today to discuss your needs!