According to the most recent study, global cargo theft losses hit $1 billion annually. As supply chains grow more complex, keeping your product’s packaging intact isn’t optional—it’s a security priority. Businesses now face rising risks from theft, tampering, and lost stock, especially during transit and at retail checkout points.

Tamper tags are one of the most effective tools to protect high-value items and maintain chain-of-custody. These small additions can stop shrinkage, flag unauthorized access, and give customers peace of mind. In this guide, you’ll learn what tamper tags are, how they work, and how to choose the right type for your store, warehouse, or shipping operation.

What Are Tamper Tags?

Tamper tags are security tools designed to show visible or electronic signs when a product, package, or container has been tampered with. They’re often attached to items at risk of theft, loss, or unauthorized access. Some tags break apart when removed, while others trigger alerts using RFID or electronic article surveillance (EAS) systems.

It’s easy to confuse tamper tags with security labels, seals, or tamper-evident tapes, but each works differently. Seals usually lock or close a container. Labels might show a “void” message when peeled. Tapes stick across flaps. Tamper tags often use loop designs, serial numbers, or barcodes, and stay attached to one key point of entry, like a bag zip, box handle, or latch.

In high-risk retail stores, warehouses, or export chains, tamper tags support wider anti-theft and chain-of-custody strategies. They’re a practical way to protect merchandise, track movement, and prove items weren’t tampered with during storage or delivery. When combined with digital systems, they offer both security and traceability.

How Tamper Tags Work?

Tamper tags do more than just stick on a product—they become part of your item’s security system. Once fixed, they act like silent barriers. Each tag adds a layer of protection that’s either mechanical, visual, or digital. Their job is to make tampering difficult to hide and easy to track.

Here’s a breakdown of how they work:

- Breakable materials: Tags tear, snap, or leave marks when removed. Any force applied beyond the allowed x 1.5 strength limit will cause visible damage.

- Hidden messages: “VOID” signs or patterns appear after tampering, clearly showing interference.

- Unique codes: Barcodes or serial numbers break when the tag is damaged, preventing reuse.

- RFID/NFC tech: Built-in circuits trigger alerts or log changes if tampered with.

- Scan feedback: Any changes in the scanned data can be detected instantly.

These features make tamper tags useful in retail, shipping, pharma, and exports. They help track packages, prove authenticity, and block sneaky access along the supply chain.

Types of Tamper Tags Used in Packaging & Logistics

Tamper tags come in many forms and varieties. And below are the most common types used across packaging and logistics, along with how they help protect your goods and strengthen your chain-of-custody systems.

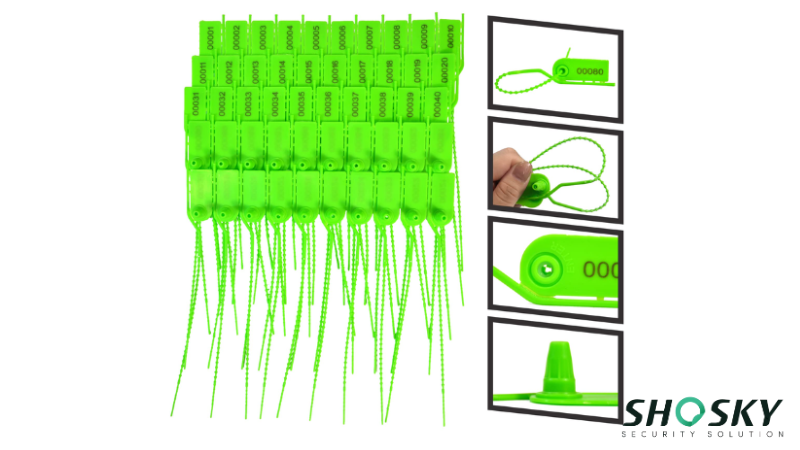

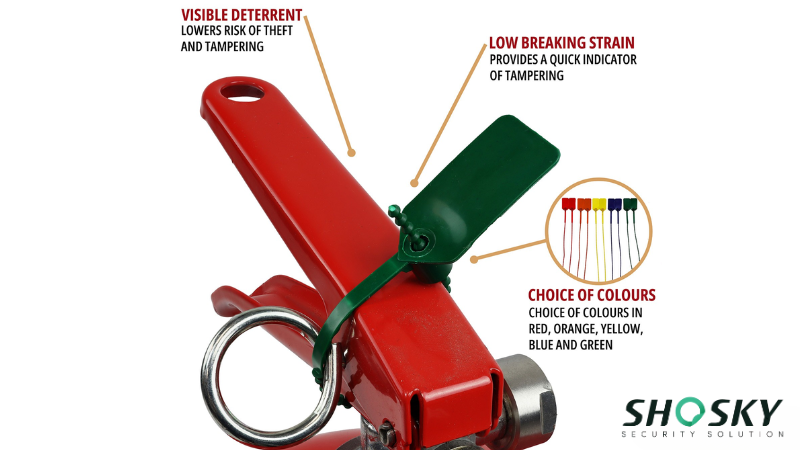

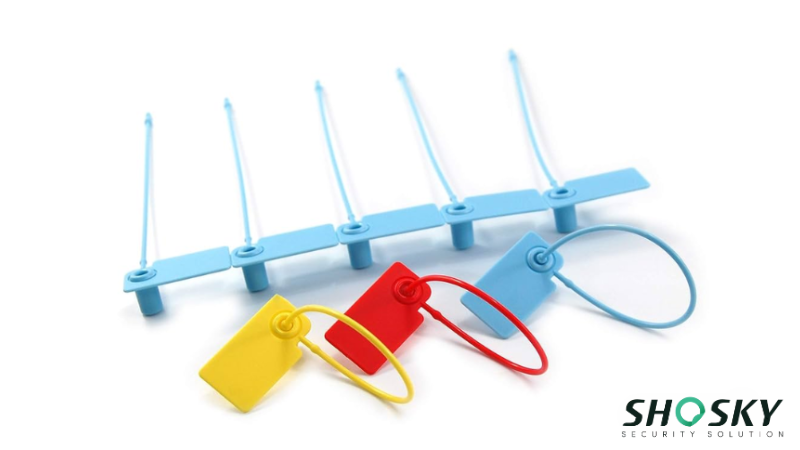

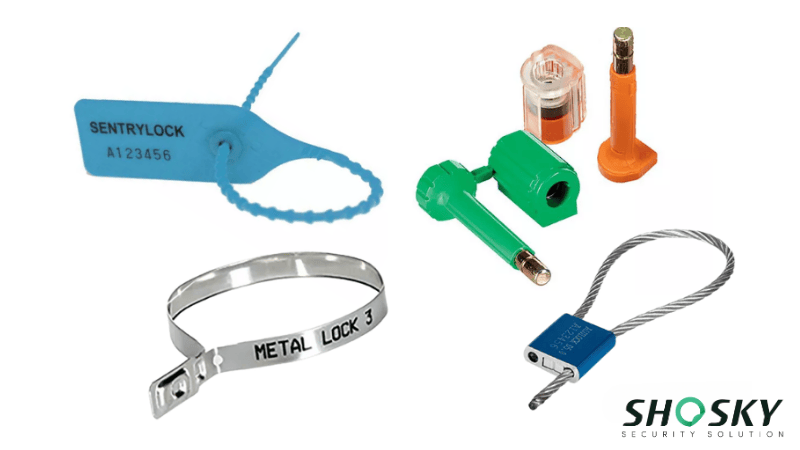

1. Plastic Pull-Tight Tags

Pull-tight tamper tags are made to wrap securely around handles, zippers, or closure points. Once fastened, they can’t be removed without cutting. So, any tampering can be easily detected. They’re often used in retail stores, warehouses, and logistics hubs for added security.

Pull-tight tags work well for bags, cabinets, and containers in transit. Some come with serial numbers or barcodes to help track inventory and improve chain-of-custody. They’re a low-cost way to protect your stock without adding extra bulk to your packaging.

2. RFID-Enabled Tamper Tags

These electronic article surveillance (EAS) tags offer both physical tamper detection and digital tracking. If broken or removed, they trigger alerts through connected RFID systems. That makes them ideal for high-risk items or long shipping routes.

Many retailers and exporters use RFID-enabled tags and RFID-enabled bags to monitor movement in real time and reduce theft or loss. Combined with deactivation tools at checkout, these tags let you trace exactly when and where an item was tampered with or removed from its assigned path.

3. Adhesive Tamper-Indicator Tags

These tags act like security labels but with one critical feature—they reveal visible proof when someone tampers with a package. They stick directly onto product packaging, box flaps, or closure points. Once removed or disturbed, they leave behind a “void” message, break apart, or change color, depending on the material and design.

Because they’re flat and lightweight, adhesive tamper tags are ideal for e-commerce shipments, pharmaceutical packaging, and small retail items. Many are designed to include serial numbers, barcodes, or QR codes, making it easier to track products, reduce theft, and flag any tampered items before they reach the store or checkout.

4. Metal Locking Tags

Built for strength and security, metal locking tags are used where plastic or adhesive tags aren’t strong enough. They’re made from aluminum or stainless steel and lock tightly into place, usually with a numbered seal or permanent closure.

These are common in cargo, air freight, and international shipments where high-value items are at stake. You’ll find security labels on containers, drums, and warehouse doors—anywhere that removal or tampering must be clearly visible and physically hard to achieve.

Tamper Tags vs. Other Tamper-Evident Tools

Not all tamper-evident tools work the same way. Some offer better visibility, others support tracking, and a few are designed for very specific use cases like export containers. The following table gives a side-by-side look at how tamper tags compare with other common options in key areas like reusability and tamper visibility.

| Security Method | Reusability | Tracking | Tamper Visibility | Best For |

|---|---|---|---|---|

| Tamper Tags | ❌ No | ✅ Optional | ✅ High | Transit, access points |

| Tamper-Evident Tape | ❌ No | ❌ | ✅ Medium | Packaging flaps |

| Void Labels | ❌ No | ✅ Serial | ✅ High | Product packaging |

| Bolt/Cable Seals | ❌ No | ✅ Yes | ✅ High | Cargo and export containers |

Tamper tags tend to be the go-to when you need frequent checks and want high visibility at a glance. That star-level visibility is their key strength. Still, other tools—like bolt seals or serial-labeled void stickers—might be the better fit based on how often you ship, what you ship, and where it’s going. Choosing the right tool depends on frequency, risk, and what’s at stake.

Industries That Rely on Tamper Tags for Product Security

Tamper tags play a key role in industries that rely on product safety and brand trust. Different sectors use them in different ways—here’s a quick look:

1. Apparel and Footwear

Clothing brands and shoe manufacturers use tamper tags and security labels to stop theft and verify authenticity. These tags are often placed on high-value or limited stock, making removal difficult without damaging the box or label. Some retailers also attach tags to returnable goods to confirm they haven’t been worn or swapped.

Most tamper tags in this sector are paired with barcode or RFID systems for inventory control. This helps retail stores reduce losses and keep track of items across locations. In large chains or franchise stores, it’s a practical way to manage high SKU counts and prevent shrinkage without slowing down store operations.

4. Logistics and Warehousing

Tamper tags and loop seals are used to protect cartons, crates, and containers from being tampered with during moving through third-party logistics hubs. These security tags make sure the goods weren’t tampered with while in transit or during storage. When items change hands several times, a broken seal is an instant red flag.

In busy warehouses, tamper-evident tags reduce internal losses and wrong deliveries. Some tags include tracking data or shipment IDs, improving sorting frequency and flow. For high-risk material like pharmaceuticals or electronics, this added control supports supply chain accuracy and checkpoint-level validation.

2. Electronics

High-value electronics like phones, laptops, and gaming gear are often sealed with tamper tags to protect against interference during shipping, warehousing, or display. These tags show clear signs of tampering so customers, resellers, and buyers can detect if the box was opened or altered. That’s especially useful for refurbished units or returns.

Some tamper tags in this category carry QR codes, serial numbers, or NFC chips. These features support warranty activation, support requests, and product verification. For companies offering buy-back or trade-in programs, such traceability helps retailers ensure authenticity and prevent fraud.

5. Food and Beverage

Food brands use tamper-evident solutions to ensure perishables and premium goods remain sealed. These markers let customers know the item is safe and untouched. In retail stores or direct shipping, they add trust at the moment of sale.

Many companies pair tamper tags with freshness indicators or anti-counterfeit layers. Some include EAS features for in-store deactivation at checkout. Whether it’s a tag on a bottle cap or a seal on a shipping box, these tools are designed to show tampering and protect brand quality during product development and distribution.

3. Pharmaceuticals

Pharma companies use tamper-evident security tags to meet strict legal standards and keep customers safe. These tags seal medication boxes, blister packs, and injection kits so that any attempt to open or alter the packaging is easily detected. This helps pharmacies and hospitals reject compromised stock before it reaches patients.

Beyond safety, these labels support batch tracking and product recalls. A visible tamper tag tied to a batch or serial number helps identify faulty or counterfeit units. In regulated markets, this step is often mandatory and backed by testing requirements to confirm seal performance.

How to Choose the Right Tamper Tag for Your Operation

Choosing the right tamper tag isn’t one-size-fits-all. The best option depends on what you’re securing, where it’s going, and how it’s being handled. Each factor—product type, shipping conditions, tracking needs, and budget—can affect tag performance. The sections below break down key questions to help you find the most effective and cost-friendly match for your operation.

Start with the Item: What Needs Securing?

The first step is knowing what needs protection—a small product, a sealed container, or important documents. Tamper tags come in different shapes and functions. So, picking the right one depends on what you’re securing. For example, adhesive security labels work well on envelopes or retail boxes, while plastic or metal loop tags suit bulk shipments or locked cabinets.

Think about access points. Does your packaging have a zipper, latch, flap, or seam? Each entry point might require different tamper-evident solutions. The more exposed the product is, the higher the security tag level you’ll need to avoid unnoticed removal or tampering.

Environment: Dry, Refrigerated, International Shipping

Tags must hold up in the same environment as your product. Dry storage, refrigerated units, or international cargo each demand specific material choices. Adhesive tags may not stick properly in cold or moist conditions, while plastic loops can get brittle if exposed to extreme temperatures.

If you’re shipping across borders, also consider customs and regulations. Some countries require certified security tools for clearance. Metal locking tags and RFID-based options are popular for international shipments, where both tracking and tamper-proofing are critical to avoid delays or damaged goods.

Manual or Digital Tracking Needed?

Basic tamper tags show physical signs of interference, but some go further by supporting digital tracking. If you need proof of access time, location, or chain-of-custody, look for tags with barcodes, serial numbers, or built-in RFID or EAS features.

For high-volume operations, pairing tamper technologies with scanning or checkpoint systems helps you spot tampered items faster. Digital tools cost more upfront but reduce manual checks and help track products throughout your supply chain, all the way to checkout or return.

Budget vs. Security Level

Not every operation needs high-end tech. Your budget plays a role, but it shouldn’t come at the cost of protection. Plastic pull-tight tags are affordable and work well for bags and boxes, while RFID tamper tags offer layered security but at a higher price point.

Consider the cost of inaction—lost items, stolen stock, or tampered goods can cost far more in refunds, complaints, or damaged reputation. Aim for balance: choose a tag that fits your operation’s size, sale value, and risk level.

Working with Certified Tamper Tag Suppliers

Look for suppliers that offer tested and certified tamper tags. Verified quality means the tags behave as expected—breaking when removed, sticking to intended surfaces, and staying readable under daily handling. Ask for testing data or proof of compliance with standards like ISO or C-TPAT.

Also, check if they provide support for customization. You may need your labels or tags pre-printed with serials, barcodes, or branding. A good supplier will help match your packaging setup with the right tag type and guide you through development, application, and post-sale support.

Real-World Examples of Tamper Tag Success

Tamper tags aren’t just theory—they’re actively solving real problems across industries. From global shipping to high-end retail, brands are using them to prevent theft, reduce stock loss, and improve traceability. The right tag ensures you can catch tampered items early, pass audits, and avoid costly returns or claim disputes. Here are a few examples of brands using them:

- Maersk Logistics added serialized tamper tags to container doors in high-risk ports. This small change helped cut claim disputes by 40% across multiple shipping lanes, especially for goods moving through Southeast Asia.

- McKesson, one of the largest medical distributors, uses RFID-enabled tamper tags to meet strict regulatory checks in the U.S. and Europe. These tags help them confirm package integrity during cold-chain transport and speed up customs inspections.

- Amazon Fulfillment Centers deploy barcode tamper tags on select electronics and small gadgets. This boosts item-level tracking and gives them a way to flag tampering during packing, transit, or return processing.

These real-world cases prove that tamper tags aren’t just about checking a box—they’re practical tools for protecting your brand, your bottom line, and your customers. Whether you’re shipping internationally or managing high-turnover stock, the right tag makes the difference between catching an issue early or paying for it later.

FAQs

Can tamper tags be reused?

No, most tamper tags are single-use by design. Once tampered with or removed, they show visible damage and can’t be reattached.

Are tamper tags compliant with ISO or C-TPAT?

Yes, many tamper tags meet ISO 17712 and C-TPAT standards, especially those used in cargo security and international shipping.

What’s the cost difference between manual and RFID security labels?

Manual security labels are much cheaper upfront, while RFID tags cost more but offer added benefits like real-time tracking and data logging.

Conclusion

Tamper tags offer a simple, effective way to protect your products, packaging, and reputation. If your business handles valuable items, sensitive shipments, or bulk inventory, using tamper-evident solutions and tamper tags isn’t optional—it’s smart risk management. Choose the right type, apply it correctly, and make product security a consistent part of your process.

Secure It Right with Shosky Security’s Tamper Tag Solutions

No matter your industry, Shosky Security offers tamper tags built for real-world use. Need fast shipping? Need something custom? We’ve got you covered with tags that stand up to tough handling. Talk to us and order the tamper tag system you can rely on!