Counterfeiting and product tampering pose significant threats to businesses and consumers alike. Ultra-destructible labels, one of the most trusted tamper-evident solutions, provide a powerful line of defense by leaving undeniable evidence of tampering.

This article breaks down exactly what an ultra-destructible label is, the science behind its fragmentation, detailed types tailored for specific surfaces, and best practices for implementation. Explore how industries across the board are using this innovative measure to maintain the integrity of their products and prevent fraud.

What is an Ultra-Destructible Label?

The ultra-destructible label (often referred to as a destructible vinyl label) is a security tool specifically designed to prevent counterfeiting and unauthorized access.

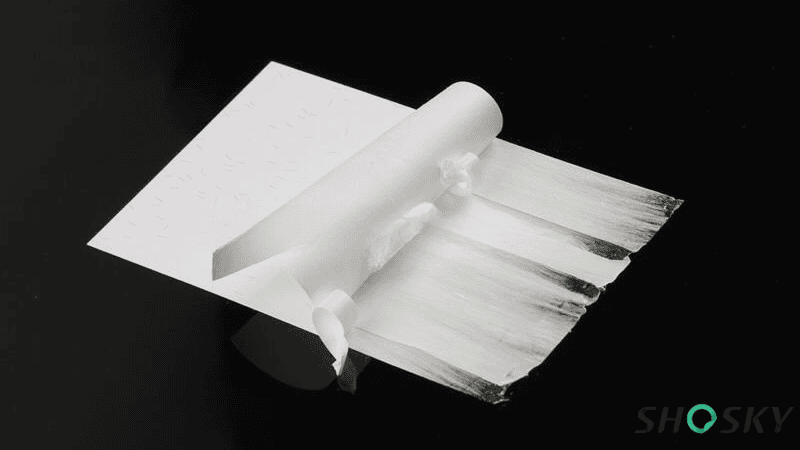

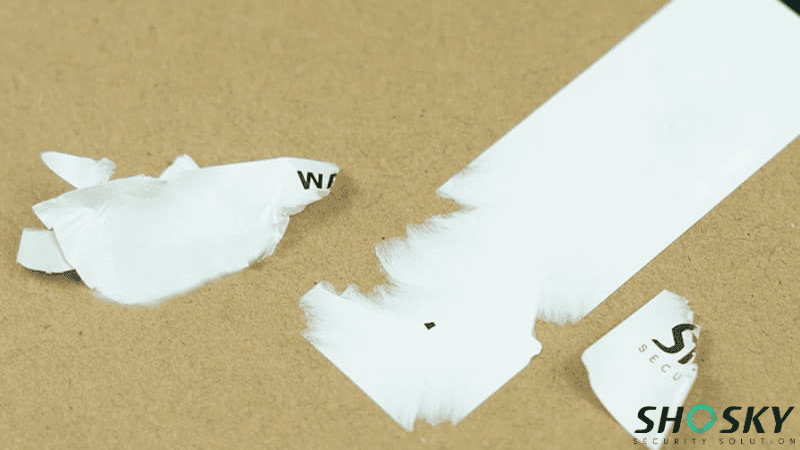

Once applied, it cannot be removed in one piece. Unlike standard stickers that peel off cleanly, any attempt to peel a destructible label causes the material to fragment into tiny pieces, leaving clear evidence of tampering.

The working mechanism of these labels is simple yet highly effective, relying on a delicate balance of engineering and material science:

- Powerful Adhesive: A high-tack, permanent adhesive is used to create a bond to a variety of surfaces (including metal, plastic, and glass) that is stronger than the internal cohesive strength of the label’s face material.

- Low Tensile Strength Material: The labels are made from a special destructible vinyl (or similar material) engineered with low tensile and internal cohesive strength. This means the material itself is deliberately weak and fragile.

- Irreversible Fragmentation: When a user attempts to peel the label, the strong adhesive holds the bottom layer to the surface. However, the upward stress causes the weak face material to tear and break into hundreds of tiny fragments, making reapplication impossible.

This irreversible damage is why ultra-destructible labels are used across industries like electronics, pharmaceuticals, and luxury goods to ensure product authenticity and customer trust. Their tamper-evident properties make them a critical tool for safeguarding high-value items.

Types of Ultra-Destructible Labels

Ultra-destructible labels are not a “one-size-fits-all” solution. Depending on your surface type (curved vs. flat) and environment, you need specific grades of brittleness.

Below is a detailed look at the specific types we engineer at Shosky Security, keeping your specific application needs in mind.

1. Co-extruded Destructible Labels

These labels are among the most widely used types of ultra-destructible labels in the market today. Made from PP synthetic paper, co-extruded destructible labels are designed to adhere effectively to uneven or flexible surfaces. Their primary function is to self-destruct into small fragments upon any tampering, providing a clear and irreversible indication of unauthorized access.

Additionally, the excellent printability of co-extruded labels makes them suitable for displaying critical information like logos, barcodes, or serial numbers clearly and durably.

- Material Composition: PP synthetic paper with a balance of stiffness and flexibility.

- Key Features: Excellent printability for logos/barcodes; withstands temperatures from -5℃ to 80℃; durable for both indoor and outdoor use.

- Best Application: Logistics, supply chain tracking, and general packaging, where surfaces might be slightly uneven.

2. Foamtac Destructible Label

Foamtac destructible labels are made from a foam-like vinyl material that provides elasticity along with waterproof and oil-proof properties. Their unique layering effect ensures that removing these labels results in complete destruction, leaving behind only residue, so they cannot be peeled off entirely or reused.

- Material Composition: Polystyrene (PS) face stock with a film thickness of 165 microns.

- Key Features: Waterproof and oil-proof; thicker foam-like texture; aggressive acrylic adhesive; unique layering effect for high security.

- Best Application: High-value asset tracking in demanding environments where moisture or oil is present.

3. Destructible Labels HG80 & HK80

HG80 and HK80 destructible labels are made for medium to large-sized tamper-evident applications. These labels use low-brittle-grade polyethylene film that fractures irreversibly into fragments when tampered with. They are designed for operational efficiency, depending on whether you need rolls or sheets.

- Material Composition: Low-brittle-grade polyethylene film (80-micron thickness).

- Key Features: Excellent printing performance; die-cutting compatibility; withstands -5℃ to 80℃; HG80 comes in rolls, HK80 comes in sheets.

- Best Application: Large flat surfaces such as shipping crates, computer towers, machinery, or sealing larger boxes.

4. Destructible Labels MG80

MG80 destructible labels are medium-brittle-grade vinyl labels designed for small to medium-sized applications, particularly those with curves. Unlike highly brittle labels that might snap when bent, the MG80 conforms well to irregular surfaces while still breaking apart into tiny flakes upon tampering.

- Material Composition: Medium-brittle-grade vinyl with 80-micron polyethylene film.

- Key Features: Verified flexibility for curved surfaces; impossible to reuse; compatible with various printing methods.

- Best Application: Curved surfaces like jar necks, cable seals, or small, rounded electronic components.

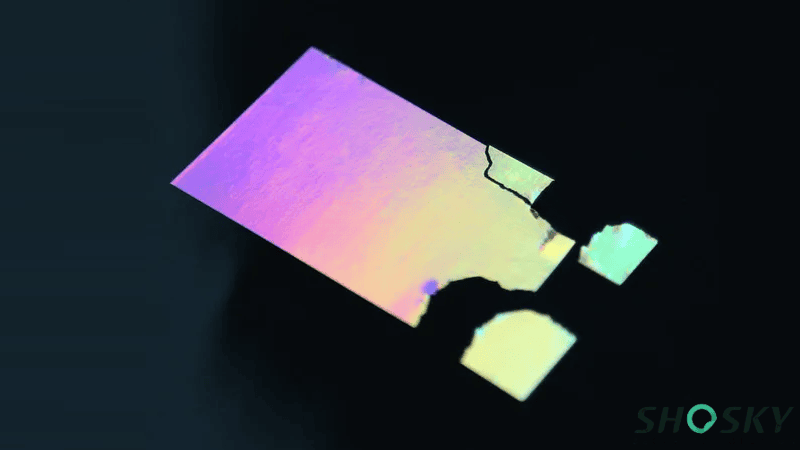

5. Hologram Destructible Label

Hologram destructible labels combine security with visual appeal, featuring a holographic effect on destructible vinyl material. The holographic finish adds an extra layer of sophistication and authenticity to products, making them extremely difficult to counterfeit.

- Material Composition: Polyethylene (PE) destructive film (70 microns) with a holographic layer.

- Key Features: Dual security (Fragmentation + Holography); visually striking; cannot be repositioned.

- Best Application: Anti-counterfeiting for luxury goods, official documents, and high-end electronics where brand image is paramount.

Benefits of Ultra-Destructible Labels

Ultra-destructible labels provide a critical layer of protection by preventing product tampering and theft. Their design ensures that any attempt to remove or alter the label results in visible damage, offering an effective deterrent to fraud and unauthorized access.

In addition to enhancing security, ultra-destructible labels play a key role in building customer trust and protecting a brand’s reputation. When consumers see tamper-evident labels, they feel assured that the product they are purchasing has not been compromised.

These labels offer strong protection against counterfeiting and fraud, making it difficult for counterfeit products to be passed off as genuine. Their destructible nature ensures that any tampering is immediately evident, protecting the brand and consumers from fraud.

With their versatility, ultra-destructible labels can be easily applied across various industries, including electronics, pharmaceuticals, and luxury goods, ensuring a secure and reliable solution for a wide range of applications.

Ultra-Destructible Labels vs. VOID Labels

A common question we receive is: “Should I use a Destructible Label or a VOID Label?” While both are tamper-evident, they function differently.

Ultra-Destructible Labels rely on the material breaking apart. VOID Labels (typically Polyester/PET) rely on the adhesive separating to leave a message (like “VOID” or “OPEN”) on the surface while the label peels off relatively intact.

Here is a comparison table to help you decide:

| Feature | Ultra-Destructible Labels (Vinyl/PE) | VOID Polyester Labels (PET) |

|---|---|---|

| Tamper Mechanism | Fragmentation: Breaks into tiny pieces like an eggshell. | Pattern Release: Leaves a "VOID" or "OPEN" message on the surface. |

| Reusability | Impossible. The label is destroyed. | Impossible to re-stick without showing the "VOID" pattern. |

| Surface Suitability | Excellent for both smooth and slightly textured surfaces. | Best for smooth, non-porous surfaces (glass, metal, glossy plastic). |

| Flexibility | Moderate to High (MG80/Co-extruded types). | Low (PET is stiffer). |

| Primary Use Case | Warranty seals over screw holes; Asset tags; Anti-counterfeiting. | Packaging seals (box closures); Software seals; Door seals. |

| Visual Deterrent | High. The fragmented mess is immediately obvious. | High. The hidden message is revealed instantly. |

Applications of Ultra-Destructible Labels

The versatility and tamper-evident nature of ultra-destructible labels make them a perfect fit for a wide range of industries where security and product integrity are non-negotiable.

Automotive & Aerospace Industries

In the automotive and aerospace sectors, ultra-destructible labels are essential for ensuring the safety, authenticity, and traceability of critical components. They are applied as authenticity and security labels for aerospace equipment and tools, guaranteeing that only genuine, certified parts are used in aircraft and vehicles.

Additionally, ultra-destructible labels are often used on maintenance and inspection records, providing proof that these crucial documents have not been tampered with.

Pharmaceuticals & Healthcare

In the pharmaceutical and healthcare industries, ultra-destructible labels play a vital role in maintaining the safety and integrity of medical products. They are applied to prescription bottles and packaging, ensuring that they are secure and have not been tampered with.

These labels also protect medical kits and diagnostic equipment, helping to prevent counterfeiting and safeguard consumer health.

Luxury Items & Brand Protection

Luxury brands rely heavily on ultra-destructible labels to maintain their reputation and combat counterfeiting. These labels are used as tamper-evident seals for products like perfumes, watches, and other high-end items, ensuring their authenticity and protecting consumers from fraudulent goods.

Ultra-destructible labels are also applied to packaging to preserve the integrity of the product and maintain consumer trust, making them a crucial tool for luxury brand protection.

For electronics and high-value goods, ultra-destructible labels offer protection against tampering and theft.

A major laptop manufacturer uses ultra-destructible vinyl labels as a warranty seal over the screw holes on their devices. If a customer attempts to open the device for an unauthorized repair, the label fragments, making it impossible to reapply and instantly voiding the warranty. This saves the company thousands in fraudulent repair claims.

These labels are typically applied as warranty seals on electronic devices, ensuring that the product has not been opened or altered before purchase. Additionally, custom security features like barcodes and holographic printing technologies are often incorporated into ultra-destructible labels, enabling better tracking and verification of authenticity.

Government & Legal Sectors

In government and legal sectors, ultra-destructible labels are invaluable for securing sensitive documents, evidence, and official equipment. They are used on evidence bags in law enforcement, ensuring that no tampering has occurred with critical materials. These labels are also applied as seals on secure envelopes and official documents, providing clear evidence of any unauthorized access.

These diverse applications highlight how ultra-destructible labels provide a universal solution for protecting assets, ensuring compliance, and building trust in a world where security is paramount. They prove that a small, simple label can have a massive impact on brand reputation and consumer safety.

The Ultimate Buyer’s Guide: Selection & Customization

Choosing the right security label involves two steps: first, selecting the right base material for your environment, and second, adding customization features to meet your security level.

Step 1: Choosing the Right Label Material

Selecting the right ultra-destructible label is essential to meet your specific application requirements and ensure optimal performance. Below are key factors to consider when choosing the right ultra-destructible label for your needs:

- Material: Select from options like vinyl, polyester, or specialty materials based on your industry and application.

- Adhesive: Consider adhesive strength, whether for permanent application or temporary use.

- Durability: Ensure the security labels can withstand environmental conditions such as heat, moisture, and abrasion.

- Tamper-Evidence: Choose labels that completely destroy or display tamper-evident messages when removed.

Besides, when selecting ultra-destructible labels, it’s equally important to partner with a trusted supplier who has experience in producing tamper-evident labels. Choose a manufacturer with a solid track record to ensure product quality and reliability.

Make sure the supplier meets industry standards like RoHS or ISO certifications and offers support like consultation and sample testing. This ensures the labels meet your specific operational, security, and branding needs.

Step 2: Customization Options (Overt & Covert Security)

Once you have chosen the material, you can enhance security through customization.

Overt Features (Visible to the Eye):

- Variable Data Printing: We can print sequential numbering, barcodes, or QR codes on every label. This is crucial for asset tracking and inventory management.

- Holographic Foils: As mentioned in the types section, adding a hologram makes the label virtually impossible to photocopy or reproduce.

- Brand Customization: Full-color printing of logos and warning text (“Warranty Void If Removed”) reinforces brand identity.

Covert Features (Hidden Security):

- UV Invisible Ink: We can print markings or text that are invisible to the naked eye and only appear under UV light. This is a powerful tool for verifying authenticity without the counterfeiter knowing.

- Micro-text: Extremely small text that looks like a line to the naked eye but can be read under magnification.

Step 3: Partnering with a Trusted Supplier

Finally, it’s equally important to partner with a trusted supplier. Choose a manufacturer like Shosky Security with a solid track record. Make sure the supplier meets industry standards like RoHS or ISO certifications and offers support like consultation and sample testing. This ensures the labels meet your specific operational, security, and branding needs.

Best Practices for Using Ultra-Destructible Labels

To get the most out of ultra-destructible labels, it’s important to follow best practices for application.

Start by ensuring that the surface is both clean and dry before applying the label. Any dirt, dust, or moisture can interfere with the adhesive, reducing its effectiveness and the label’s ability to stick properly.

Next, using the correct size and shape of the label for the surface is vital. A security label that is too small or large for the designated area may not function as effectively in its tamper-evident role. Additionally, the label could be compromised in terms of security if it doesn’t fully cover the intended area, leaving parts of the surface vulnerable to tampering.

It’s also important to handle the labels carefully. Avoid touching the adhesive side directly with your fingers, as oils, dirt, or other residues from your hands can interfere with adhesion, reducing the overall performance of the label. To maintain the integrity of the adhesive and ensure the label sticks securely, it’s best to handle the label by its edges.

Lastly, always test the label on a small section of the surface before applying it to the full area. This step helps confirm that the label adheres correctly and that it’s easy to apply without damaging the product. A test run allows you to verify that the label provides the desired tamper-evident effect and ensures its durability under specific conditions, avoiding any issues before you proceed with larger applications.

FAQs

Q1: What makes ultra-destructible labels different from tamper-evident labels?

Ultra-destructible labels break into small fragments when tampered with, offering visible proof of interference, whereas tamper-evident labels may leave messages or residue without breaking apart.

Q2: Can ultra-destructible labels be reused?

No, these labels are designed to break apart during removal, making them impossible to reuse or reapply.

Q3: Are ultra-destructible labels suitable for all types of products?

Yes, they are suitable for most surfaces. They offer unparalleled protection against tampering, counterfeiting, and unauthorized access. Their durability and customization options make them an essential solution for industries prioritizing security.

Conclusion

Ultra-destructible labels offer unparalleled protection against tampering, counterfeiting, and unauthorized access. Their durability, customization options, and ability to provide visible proof of interference make them an essential solution for industries prioritizing security and authenticity. By investing in these advanced labels, businesses can safeguard their products, strengthen their brand reputation, and build trust with customers.

Get Your Ultra-Destructible Labels from Shosky

Shosky is a trusted leader in tamper-evident solutions, offering ultra-destructible labels tailored to your industry’s needs. With a commitment to quality, customization, and fast delivery, we ensure that your products remain secure and authentic. Contact us today to explore our innovative labeling solutions and enhance your brand protection!