Shipping cargo overseas brings the risk of theft and tampering during transit. This can lead to financial losses and damaged reputations. Container seals can be useful in this case, but with so many options available, choosing the right one can be difficult.

This article gives you knowledge on the different types of seals, their specific roles and benefits, how to apply them, their selection criteria, and important tips on solving typical problems you might face when using container security seals.

The Role of Container Seals in Supply Chain Security

Container security seals serve a wide range of purposes beyond simply locking a container shut. They play a vital role in international shipping operations by ensuring security, regulatory compliance, and cost efficiency. The table below outlines the key benefits of container seals and how they contribute to secure cargo transportation:

| Role/Benefit | Description |

|---|---|

| Security | Prevents unauthorized access to container contents using durable designs like metal bolts, bars, and cable seals. |

| Tamper Evidence | Indicates if a container has been opened or interfered with during transit; usually done with plastic or metal indicative seals. |

| Regulatory Compliance | Required for customs clearance. Must be ISO 17712 certified. Seals are engraved with type codes: I (Indicative), S (Security), H (High Security). |

| Cargo Integrity | Ensures goods remain untampered and uncontaminated, maintaining the condition from origin to destination. |

| Shipment Tracking | Each seal has a unique number linked to container contents, aiding in logistics, identification, and tracking throughout the route. |

| Cost Efficiency | Reduces losses from theft and damage, minimizing insurance claims and avoiding unnecessary additional security expenses. |

These benefits illustrate why container seals are more than just a lock. They are a core element of safe, transparent, and efficient international logistics. In the following section, we’ll explore the main types of container seals and their specific uses.

3 Major Container Seal Types

Based on usage, there are three fundamental container seal types. Indicative, Security, and High-Security seals. These seals have marks of their initials on them, namely I, S, and H, respectively. The following section briefly explains each type.

1. Indicative Seals

As apparent from the name, these types of seals are used for low-risk or empty containers. They’re often used to check if the container has been opened or tampered with and whether it’s clean and suitable for loading or not. Such seals are also called tamper-evident seal types.

These seals don’t secure the container, as they’re easily breakable by hand or with standard household cutters. Indicative seals are commonly made of plastic or thin metal wires. Examples of such types of seals are:

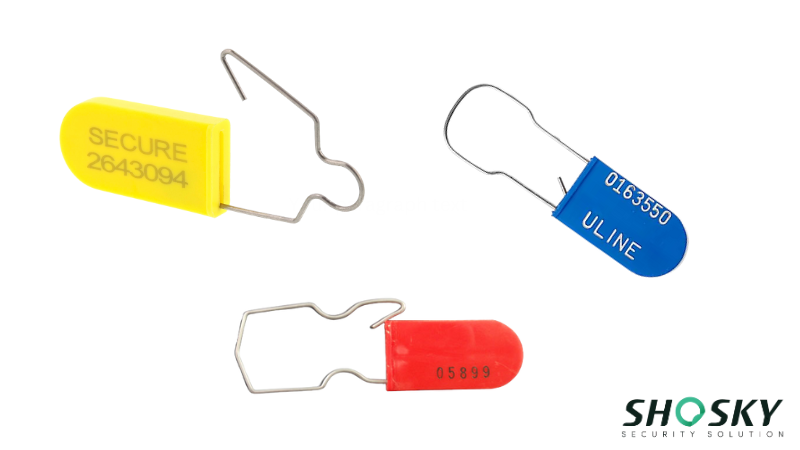

Plastic Security Seals

A plastic Seal provides evidence of tampering during transit. These seals have specific serial numbers on them so that they can’t be replaced with a new seal after they’re broken.

They’re made of cost-efficient and easily breakable materials, and it’s not advisable to use them to secure valuable cargo. A plastic seal has different designs for specific applications, which include Adjustable Length, Fixed Length, and Pull-Tight seals.

To apply, place the seal over the container hatch or access point. Tighten the seal until it’s locked in place so that it can’t be removed without breaking it. Make sure the seal number or tracking barcodes are clearly visible.

Metal Strap Security Seals

These seals have the same working principle as plastic security seals and are mainly used as indicative seals to provide tampering evidence. They’re made of a metallic strap that can be tightened to an adjustable length.

Metal Strap Security Seals can also be used as a security seal, provided they are ISO certified. These seals are of two main types: adjustable and fixed-length.

For adjustable-length seals, wrap the metallic strap around the desired opening and insert the end through the locking mechanism until it is securely fastened. If the seal includes a metal pin, insert it into the locking chamber to complete the seal.

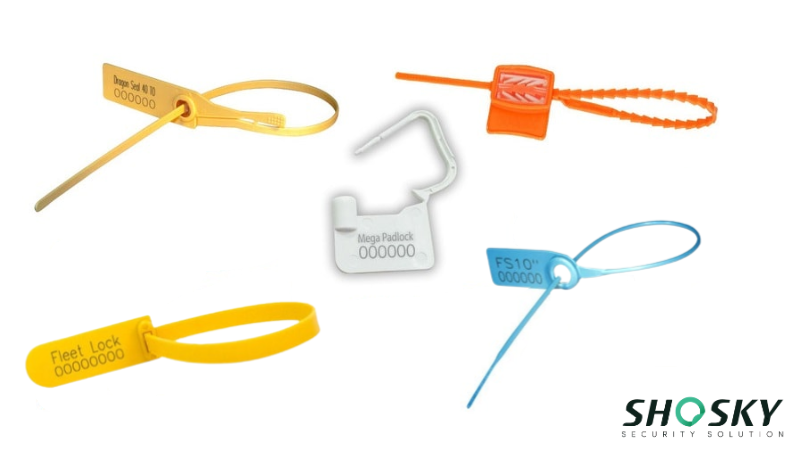

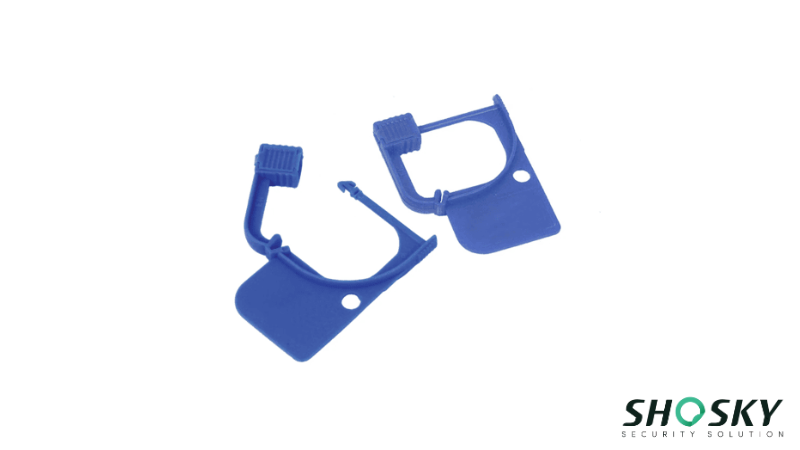

Padlock Seals

This indicative seal is designed to show visual evidence of tampering or unauthorized access. Their types include:

- Metal Hasp Seals are made from metal and are easily breakable by hand.

- Plastic Seals are lightweight and used for temporary applications.

These seals are cost-effective and easy to apply. However, they provide a lower level of security compared to high-security padlock seals, making them unsuitable for valuable cargo. They’re single-use and may not withstand harsh environmental conditions. To apply, select the appropriate type of seal, insert the seal through the shipping container door lock, and ensure it is tightly fixed.

2. Security Seals

These types of seals provide better security than indicative plastic seals. Security seals prevent theft for cargo with medium security needs. These seals are also called tamper-resistant seals.

It’s hard to remove these seals without leaving any trace of theft or tampering with the container. Security seals are mostly made of metal, and wire cutters are needed to open them. Examples of such seals are as follows:

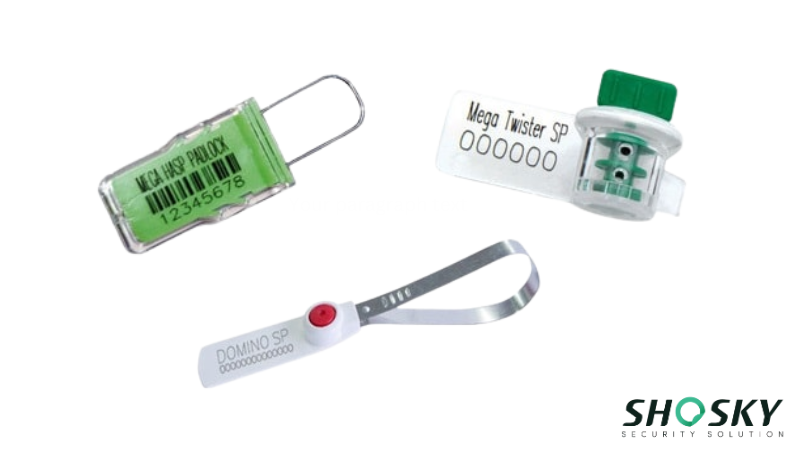

High-Strength Padlock Security Seals

Padlock security seals can also be used, depending on how strong their design is. Strong metallic padlocks that are similar in design to conventional padlocks are used for maximum security and also comply with international standards.

These seals are more expensive than indicative padlocks and require cutting tools to remove them. However, they’re durable enough to withstand extreme weather without compromising strength.

In order to apply padlock seals, first identify the type of application and select the seal that’s best suited for it. Then, thread the seal around the door hatch and close it like a simple padlock till it is tightly wound across the opening without any slack.

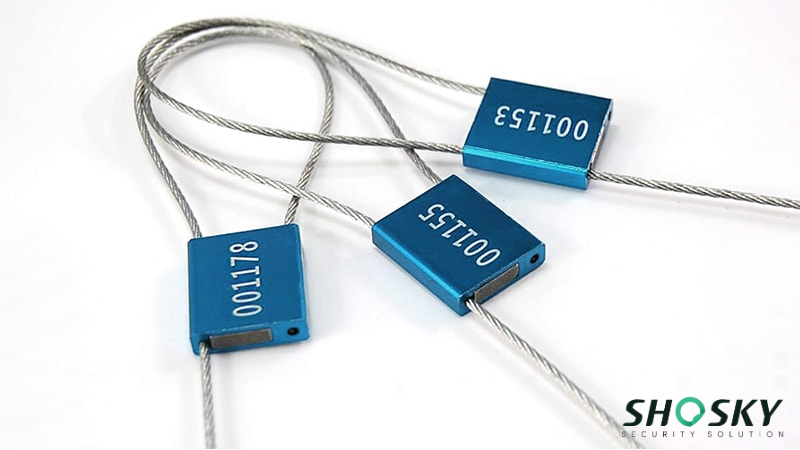

Wire/Cable Security Seals

Cable Seals use a metallic wire that is attached to a lock, similar to a plastic cable seal. Wire security seals are used for high-strength applications, and special tools are needed to remove them, like heavy-duty cutters.

Types of wire/cable security seals include:

- Adjustable cable length seals that can be used for variable-sized openings

- A fixed-length cable seal is used for non-adjustable applications.

High-security metal seals can withstand over 2000 kg of pulling force, depending on the model.

After picking the right seal strength, wind the metallic cable around the container doors and insert the end of it into the lock. Tighten the seal enough to eliminate any slack.

3. High-Security Seals

High-security container seals provide maximum resistance to tampering and unauthorized access; hence, they’re also called tamper-proof seals. These types of seals are in accordance with ISO standards, which require certain durability criteria to be met for security seals.

High-security seals are made of extremely strong metals and require specialized tools to break them. They’re used to prevent any chance of theft or tampering and are used for containers with expensive or hazardous cargo.

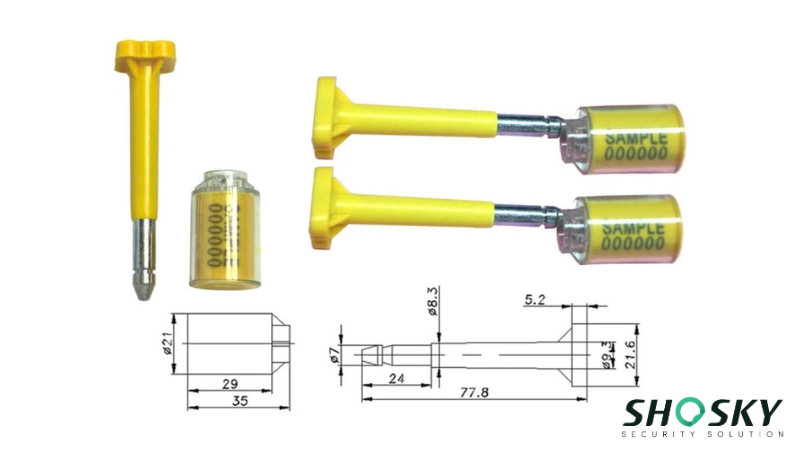

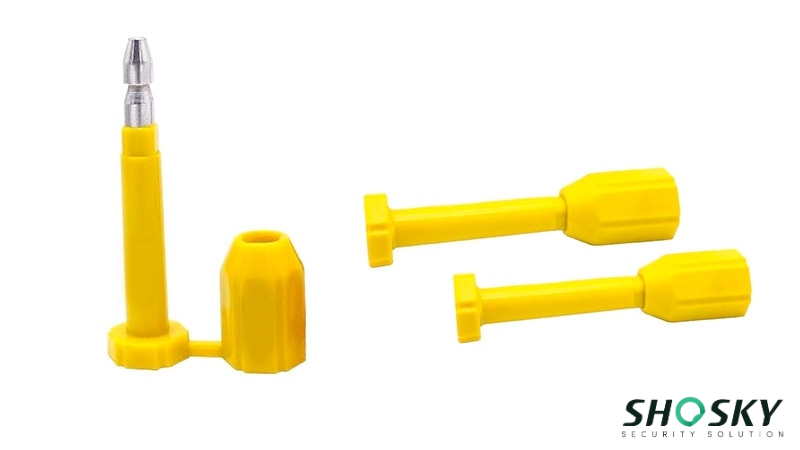

Bolt Security Seals

Bolt seals are the most commonly used high-security seals for containers. They’re made from strong carbon steel with an ABS plastic coating for clear visibility. The main purpose is to prevent containers or similar cargo-holding compartments from being opened without permission.

To apply these bolt seals, align the bolt with the locking mechanism, which, in this case, is usually a latch or a hole in the container itself. Then, push the bolt into the locking head till it snaps into place.

Be sure to confirm that it’s locked by pulling on the bolt. The bolt should also spin freely to confirm that it’s properly locked. Use bolt cutters to open the bolt seals, as they’re made for one-time use.

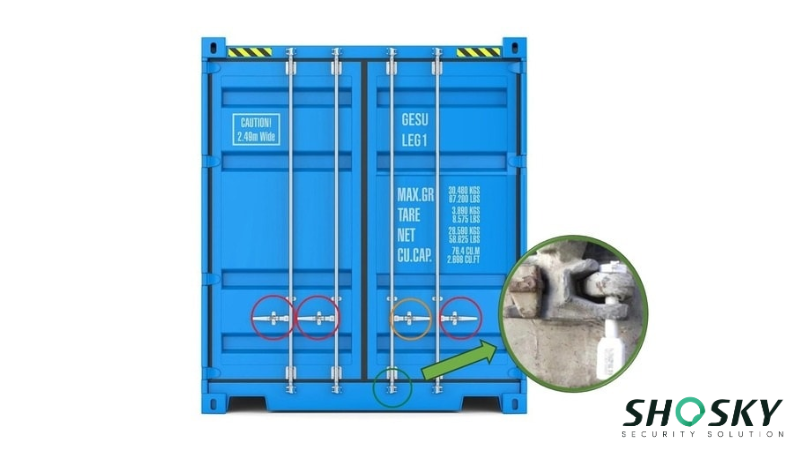

Locking Bar Security Seals

The locking bar seal is made up of a strong U-shaped metallic strap, similar to a metal strap seal, the ends of which are both attached to a locking mechanism. The design of this seal ensures that it’s tightly wound around the container door hatch without any slack, resulting in maximum tamper resistance.

This type of seal usually requires heavy-duty cutting tools to remove it, which means they’re durable and provide maximum security.

The following are the steps to apply locking bar security seals:

- First, place the two U-shaped brackets around the container’s locking rods or door handles on either side.

- Insert the main bar through the slots of both U-brackets

- Secure the locking mechanism. For the metal wire seal, loop the metal wire around the aligned holes in both U-brackets and pull tight to lock it in place. For a metal rivet/pin, insert a metal rivet or pin into the aligned holes. For the key lock, use the provided keys to secure the locking mechanism.

- Pull on the bar and brackets to ensure everything is locked firmly.

How to Choose the Right Container Seal (6 Key Factors)

Choosing the right container seal is crucial to prevent tampering and maintain the integrity of the cargo being delivered. Here are 6 key factors to consider:

Factor 1: Cargo Value and Risk (H, S, or I Seal?)

First, you have to evaluate the type of goods being shipped. High-value goods need strong and durable security seals that cannot be opened without the use of special tools, such as bolt or metal cable seals. These provide security and are harder to tamper.

While low-cost goods don’t need that much security, for this, indicative seals like plastics or metal strip seals can offer basic tamper evidence.

Factor 2: Shipment Destination & Route

Keep in mind the routes of the ship and the destination if you’re shipping overseas. Some regions are prone to theft or piracy, which requires you to use high-security seals to mitigate these risks.

You also need to comply with local shipping regulations regarding seal types because certain countries have specific requirements for container seals.

Factor 3: ISO 17712 & C-TPAT Compliance

Compliance with ISO 17712 and C-TPAT standards is essential for international shipping security. ISO 17712 is the globally recognized standard that classifies seals into three levels: Indicative (I), Security (S), and High-Security (H). Only “H” class seals meet the strength and tamper-resistance criteria required for high-risk cargo.

In the United States, C-TPAT (Customs-Trade Partnership Against Terrorism) requires all containers entering the country to use ISO 17712-certified High-Security (H) seals. This certification helps ensure consistent protection, faster customs clearance, and improved cargo traceability across borders.

Factor 4: Environmental Conditions

Environmental conditions can also impact seal performance during long-term shipment. During international freight, long distances can cause weather patterns to change abruptly throughout the journey. For example, extreme changes in temperature could damage plastic seals. This could lead to false tampering accusations.

Extreme humidity can cause corrosion to metallic seals if they’re not properly insulated, which ultimately results in a damaged seal. So it’s better to invest in high-security seals for harsh and demanding environments, compared to indicative seals, regardless of cargo value.

Factor 5: Traceability (Unique Serial Numbers)

A unique seal number can provide better traceability and accountability. These numbers assist the logistics teams in tracking shipments through various stages of transport. Each seal has a unique number, which also means you can’t replace a seal after breaking it, ultimately providing evidence of potential tampering.

Factor 5: Budget vs. Security Trade-offs

While it is tempting to just go for cheap security seals, you need to balance cost and proper security. High-security seals usually come at a higher price, as compared to indicative seals, but are crucial for successfully transporting valuable goods.

You need to consider the possibility of theft and evaluate whether the potential loss from theft or damage outweighs buying cheaper seals in order to save shipping costs.

Common Container Seal Issues and How to Solve Them

Container seals are vital for securely transporting goods overseas, but various issues can cause them to fail. Here are some common problems that occur regarding container security seals:

1. Improper Application

One of the main causes of seal failure is improper application. If the seals are not secured tightly around the opening, it causes slack and makes it easier to get damaged or tampered with without any evidence.

Solution: Ensure that personnel are trained in the correct application of seals to avoid common mistakes and accidental damage.

2. Environmental Factors

Extreme temperatures, humidity, and exposure to harmful chemicals can cause damage to seals. For example, plastic seals may become brittle in cold weather or soften in high heat, while metal seals can corrode in humid and salty environments. This happens without any actual tampering or theft.

Solution: Choose high-security seals that can withstand harsh environmental conditions and are suitable for use during long voyages.

3. Physical Damage

Seals can be prone to physical damage during the handling of containers and during transportation. This also includes crushing and cutting from mishandling the containers or the seals themselves, as well as any tampering attempts.

Solution: Conduct routine checks on seals before and after transportation to identify any potential issues early on.

4. Quality Control Issues

Using low-quality or counterfeit seals can lead to unexpected damage. Seals that don’t have their unique serial numbers clearly visible can cause problems in tracking and securing the containers.

Solution: Be sure to use only ISO-certified seals for your containers that have their unique serial numbers clearly visible for proper identification and tracking.

FAQs

Q1: Can I reuse a container seal once it’s broken?

No, container seals are typically used once. Once broken, they cannot be reapplied, ensuring that tampering is easily identifiable.

Q2: How do I choose the right seal for my cargo?

Consider the value of your goods, environmental conditions during transport, and the destination’s security requirements. High-value goods and harsh environments typically require high-security seals.

Q3: How do container seals help with shipment tracking?

Each container seal has a unique number that allows logistics teams to track shipments, ensuring the contents remain secure and helping identify any tampering or unauthorized access.

Conclusion

In conclusion, the use of container seals plays an essential role in preventing theft, tampering, and damage during international shipping. Whether you choose an Indicative, Security, or High-Security seal, each type offers distinct advantages based on the level of protection required. By selecting the appropriate seal, you can ensure the safety of your cargo and maintain the trust of your customers and partners throughout the shipping process.

Ensure Maximum Protection For Your Container With Shosky!

Don’t compromise on security, so choose Shosky Security. Our range of ISO 17712-certified seals ensures your precious cargo remains safe and traceable. Get in touch with us for personalized recommendations and further details!