Every shipment carries value. That’s why ensuring goods arrive intact during shipment is a top priority for businesses worldwide. In that regard, container security seals provide a critical line of defense. These tamper-evident technology based seals act as a safeguard against unauthorized access, theft, and tampering and offer clear evidence if tampering occurs.

Whether using high-security bolt seals for industrial shipments or barrier seals for added protection—these tools are indispensable for maintaining supply chain integrity. This comprehensive guide will explore the various types of container security seals, their importance in mitigating tampering risks, and their role across the shipment industry. Let’s get to it.

What Are Container Security Seals?

Container security seals are specially designed devices that secure containers. Their primary purpose is to create a tamper-evident barrier, ensuring that any breach in the container can be quickly identified and addressed. This feature ensures the security of goods throughout the shipping process. The way container security seals work includes two main parts.

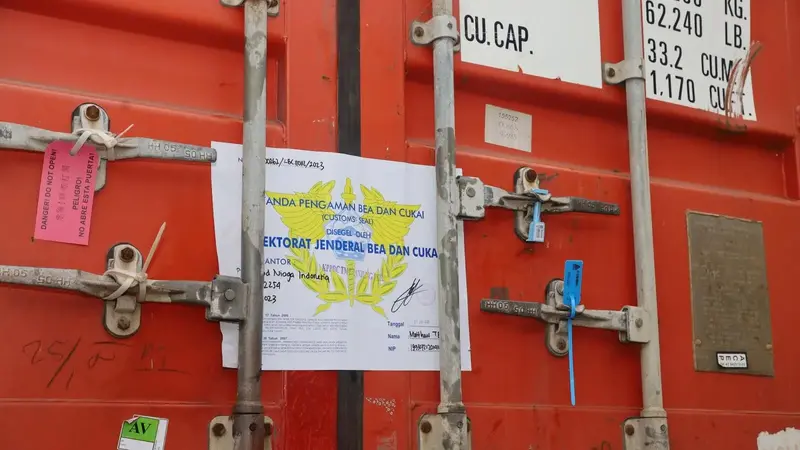

The one is that the security seal is strategically applied to key areas of the container, such as the locking mechanism, door handles, or any other vulnerable points (mostly, they are applied using wires) that could be targeted for unauthorized access.

The other one is that if someone tries to open or manipulate the seal, the anti-tamper design ensures there are visible signs of interference. This may include a broken seal, a distorted wire, or damaged locking components.

Container Seal Number: What is it?

A container seal number is a unique identification code assigned to a specific security seal used to improve shipping container security. This number is often alphanumeric and is structured to be one-of-a-kind—ensuring that each seal can be traced back to the shipment it is attached to. When it comes to sealing something, the seal number typically appears on a label or the seal itself and may include a combination of letters, numbers, barcodes, or even QR codes.

These identifiers are crucial for tracking the movement of containers through the supply chain. By recording and monitoring the seal number, companies can confirm the integrity of their shipments and identify any potential tampering or theft during transit. The uniqueness of the seal number also helps in verifying the authenticity of the seal, preventing fraud and counterfeit activities.

Types of Container Seals

Here are the main types of container seals: bolt seals, barrier seals, cable seals, plastic Seals, adhesive seals and labels, and electronic seals. Now, let’s take a closer look at each of these types, their features, and how they are used.

Bolt Seals

Bolt seals are among the most commonly used high-security seals to seal something shipping containers. They consist of a solid steel bolt and a locking mechanism, offering exceptional resistance to tampering. Their length varies greatly (from a few centimeters to over a meter), depending on the application; width typically ranges from 0.5cm to 2cm; thickness is usually a few millimeters.

How They Work: The steel bolt is inserted through the container’s locking hasps, and the locking head is pressed onto the bolt until it clicks into place. This forms a robust seal that can only be removed with specialized cutting tools.

Key Features:

- Made from high-strength steel for durability.

- Customizable with sequential numbering or barcode cases for enhanced traceability.

- ISO 17712-compliant to meet global shipping regulations.

Applications: Securing cargo containers during transit across sea, land, and air. Preventing unauthorized access in freight forwarding and logistics. Widely used in industries such as manufacturing, retail, and international trade.

Barrier Seals

Barrier seals provide a higher level of security to seal something by combining physical strength with anti-tamper features. They are typically constructed from durable materials like steel or aluminum, making them difficult to breach without significant effort. Their dimensions are highly variable and depend entirely on the container opening they are made to secure. They can range from small strips to large sheets.

How They Work: Barrier seals are placed over container locking points, covering the entire locking mechanism. Their heavy-duty construction ensures they can only be removed using industrial-grade tools. By serving as both a deterrent and a visible sign of protection, barrier seals help secure high-value goods during transit.

Key Features:

- High resistance to cutting, prying, or drilling.

- Visible tamper indicators, such as bent or damaged components.

- Often used alongside bolt seals for double-layered protection.

Applications: Protecting high-value shipments. Ensuring compliance with international shipping regulations. Commonly used for long-haul transportation of goods.

Cable Seals

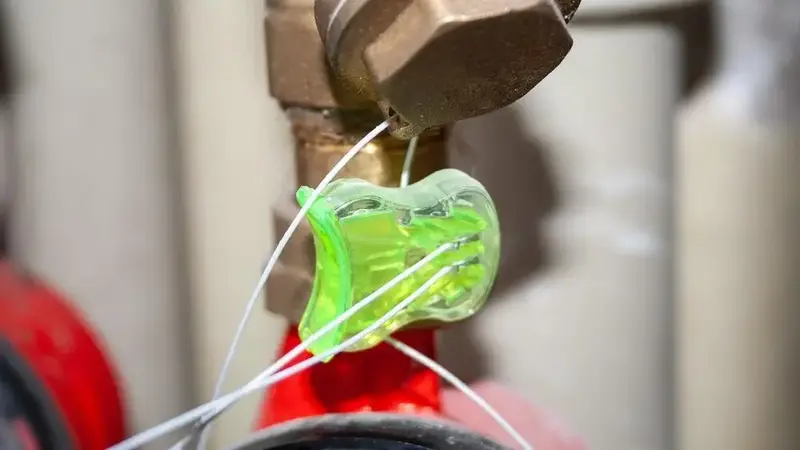

Cable seals are flexible yet highly secure seals that feature a metal wire loop and a locking body. Their adjustable length makes them suitable for a wide range of applications. Their length is highly customizable, ranging from a few centimeters to several meters; their diameter typically ranges from 3mm to 8mm.

How They Work: The cable is looped through the locking points of shipping containers and secured by inserting it into the locking body. The length of the cable can be adjusted, making it adaptable for different types of cargo. Cutting the cable requires specialized tools, ensuring tamper resistance and secure closure.

Key Features:

- Strong metal cable resistant to tampering or cutting.

- Tamper-indicating design that leaves visible damage when manipulated.

- Available in various lengths and diameters for versatility.

Applications: Securing containers, tanker trucks, and railcars. Protecting goods in storage facilities and warehouses. Used in industries where adjustable, durable seals are necessary, such as logistics and petrochemicals.

Plastic Seals

Plastic seals are lightweight and cost-effective high-security seals designed for tamper detection. They are ideal for sealing something for applications requiring lower levels of security but still demand tamper visibility. Their length and width are highly variable, depending on the application; thickness is usually a few millimeters.

How They Work: Plastic seals are applied by threading them through signature locking points of shipping containers and securing them with a self-locking mechanism. Once closed, they can only be removed by cutting, making any tampering attempt immediately noticeable. These seals are simple to use and made for one-time application.

Key Features:

- Available in various colors for quick identification.

- Customizable with serial numbers, barcodes, or logos.

- Provide visible signs of tampering when removed.

Applications: Securing less critical shipments, such as food and beverages. Often used for tamper-evident packaging in retail. Suitable for short-term or low-potential transportation.

Adhesive Seals and Labels

Adhesive seals are used to secure smaller packages and indicate tampering. These are ideal for sealing something for applications where physical barriers are impractical. Their size is extremely variable and depends on the application, ranging from a few square centimeters to much larger sizes.

How They Work: The seal or label is applied directly to the package or container. If someone attempts to remove or reposition it, the adhesive leaves behind a clear message or pattern, such as “VOID” or other tamper-indicating marks. Advanced options include dual-layer adhesives for added security.

Key Features:

- Quick, visible tamper detection with void messages or patterns upon removal.

- Customizable with branding, sequential numbers, or barcodes for traceability.

- Suitable for high-turnover industries requiring efficient strategies.

Applications: Secure sensitive products like pharmaceuticals or electronics. Protect confidential documents, cash bags, or retail goods. Ensure tamper-proofing for food and beverage packaging.

Electronic Seals

Electronic seals are advanced tamper-proofing seals that incorporate cutting-edge technology. They provide real-time tracking and monitoring and are equipped with sensors, RFID tags, or GPS capabilities. Their dimensions vary significantly based on the technology incorporated, and sizes can range from small tags to larger devices.

How They Work: Electronic seals are attached to containers and synced with a monitoring system. Sensors detect any breach or movement, immediately triggering an alert. Many electronic seals also include tracking capabilities, enabling real-time monitoring of the shipment’s location and condition.

Key Features:

- Real-time alerts for tampering or unauthorized access.

- Seamless integration with logistics software for efficient tracking.

- Data collection to enhance supply chain security.

Applications: Protect high-value shipments such as luxury goods or pharmaceuticals. It is ideal for industries like aerospace and international trade requiring 24/7 monitoring. Used in applications where compliance with advanced security standards is critical.

Key Uses of Container Protection Seals

Container protection seals serve diverse purposes across industries, offering essential safety and compliance benefits. Below are the most prominent sectors where these tools are employed.

Shipping and Freight

The freight industry relies heavily on advanced locking devices to ensure the security of goods during transportation across various modes, including trucks, rail, and sea. The container protection seals serve as the first line of defense against theft, tampering, and environmental damage, which are persistent challenges in the logistics sector.

Among the most common and effective approaches are high-durability locking mechanisms, such as bolt locks, cable seals, and high-strength barrier seals. These tools are engineered for robustness, with materials that can endure extreme weather conditions, rough handling, and even attempts at forced entry.

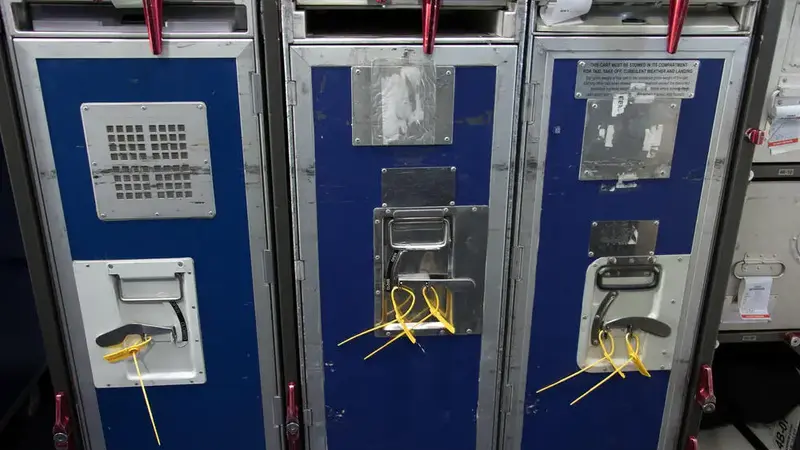

Aviation and Airport Logistics

In aviation, securing cargo, luggage, and equipment is crucial. Specialized locking seals, such as barrier locks and cable locks, are commonly used to protect cargo holds, baggage compartments, and sensitive storage areas from unauthorized access. These devices play a critical role in complying with strict aviation security regulations, offering robust protection against tampering or interference with goods.

Beyond security, their implementation also streamlines airport operations by reducing the need for time-consuming manual inspections. This enhances logistical efficiency, minimizes delays, and ensures the smooth handling of cargo and luggage, contributing to overall operational reliability in the aviation sector. Additionally, tamper-evident technology enables airports to uphold stringent security protocols, fostering passenger trust and regulatory adherence.

Banking and Cash-in-Transit Services

In the banking sector, protecting cash, sensitive documents, and other valuables during transport is essential. Specialized security seals play a critical role by adding a tamper-evident barrier to safeguard assets. These seals ensure any interference is immediately detectable, enhancing security and accountability in cash-in-transit operations.

Cash-in-transit bags incorporate advanced features like sequential numbering, barcodes, RFID tags, and anti-tamper seals. These technologies enhance traceability, deter unauthorized access, and provide reliable protection during high-risk transfers. By integrating these measures, financial institutions can minimize theft risks and maintain the integrity of their valuable shipments.

Healthcare and Pharmaceuticals

In the medical field, ensuring product safety is of utmost importance, as it directly impacts patient health and well-being. Tamper-detection fasteners play a crucial role in protecting pharmaceuticals, medical equipment, and healthcare supplies from unauthorized access or contamination. Commonly used methods, such as adhesive indicators and cable fasteners, provide clear visual evidence of tampering, enabling swift identification and response.

These protective measures help healthcare providers meet rigorous compliance and regulatory standards, safeguarding the integrity of critical products. By integrating tamper-evident seals into their supply chains, pharmaceutical and healthcare organizations can enhance patient safety, protect their brand reputation, and ensure the reliability of their products.

Food and Beverage Industry

Maintaining product integrity during food and beverage transportation is crucial for safety and quality. Sealing systems like tamper-evident caps, adhesive markers, and specialized seals safeguard goods from contamination or unauthorized access. These systems provide clear visual indicators of safety while helping companies meet stringent regulatory standards and ensure consumer trust.

Reliable sealing methods also preserve product freshness, protect brand reputation, and prevent costly recalls or legal issues. Investing in advanced container seals enables businesses to deliver safe, top-quality consumables, showcasing their dedication to food safety and strengthening their market reputation.

Who Provides Container Seals?

Container seals are provided by specialized security companies that focus on tamper-evident solutions for the logistics and transportation sectors. These providers offer an extensive range of seals, from bolt locks to cable seals, designed to meet diverse security needs. Many also provide customization options to accommodate specific industry or regulatory requirements.

Leading manufacturers of container seals adhere to global standards, such as ISO 17712, which certifies high-security seals for international shipping. These seals undergo rigorous testing for strength, durability, and tamper resistance, ensuring they meet the highest security benchmarks. This compliance reassures businesses about the reliability and effectiveness of the seals.

In some cases, logistics companies supply container seals as part of their services. However, sourcing seals directly from specialized providers offers added benefits, such as advanced tamper-evident features, traceability options like barcodes or RFID, and greater customization. Partnering with experts ensures the best protection for shipments, reducing risks of theft or tampering.

Choosing the Right Tamper-Evident Seals

The right tamper-evident seals are essential for securing goods during transportation and storage. So, businesses must carefully select seals that match the level of protection required based on the shipment’s characteristics. For high-risk items, such as valuable electronics or confidential documents, high-security seals like bolts or barrier seals are ideal.

Conversely, lower-risk shipments might benefit from cost-effective options such as plastic seals or adhesive labels. Another important factor is ease of use. The anti-tamper seal should be simple to apply and remove, minimizing disruption to logistics processes while still maintaining high-security standards.

For businesses with unique requirements, custom anti-tamper options can be made to align with specific security protocols, signature packaging needs, or branding preferences and image of the business. With careful consideration of these factors, businesses can opt for services that address their operational goals and secure their goods effectively!

FAQs

What does it mean to seal something off?

To seal something off means to close or block access to an area or object, often for security reasons. This can involve physical barriers, like locks or seals, to prevent entry, tampering, or contamination.

Can tamper-evident technology be customized?

Absolutely. The tamper-evident solutions can be customized with logos, barcodes, serial numbers, and other features to meet specific security needs.

Are there legal requirements for shipping security seals?

Yes, legal requirements for security seals exist, particularly for high-value or regulated goods. These requirements vary by industry and region.

Conclusion

The importance of container security seals in the logistics and shipping industries can’t be overstated. These seals help prevent tampering, theft, and contamination. And as security concerns continue to rise globally—container seals remain a key element in protecting cargo, reducing losses, and meeting international compliance standards. They are not just tools but a vital investment in supply chain integrity.

Invest in Reliable Security Solutions!

So, don’t JUST compromise on shipment security. Invest in tamper-evident seals with Shosky Security today and protect your goods, enhance customer trust, and meet regulatory standards! Reach out for high-quality, customizable options that meet your needs.