Investing in robust packaging solutions might seem like an added expense, but the long-term benefits far outweigh the initial costs. The tamper-evident packaging can not only protect your products from unauthorized access but also reduce product returns, minimize legal liabilities, and enhance consumer confidence.

The result is demonstrable growth: higher sales, enhanced brand loyalty, and a more dominant market presence! Here are the top ten most effective and cost-efficient tamper-evident packaging options currently available. Read on to learn about their features and overall value.

10 Popular Types of Tamper-Evident Packaging

Deciding which type of tamper-evident packaging to choose can be challenging. To help you streamline different packaging options, we’ve listed the ten most popular types of tamper-evident packaging and their uses.

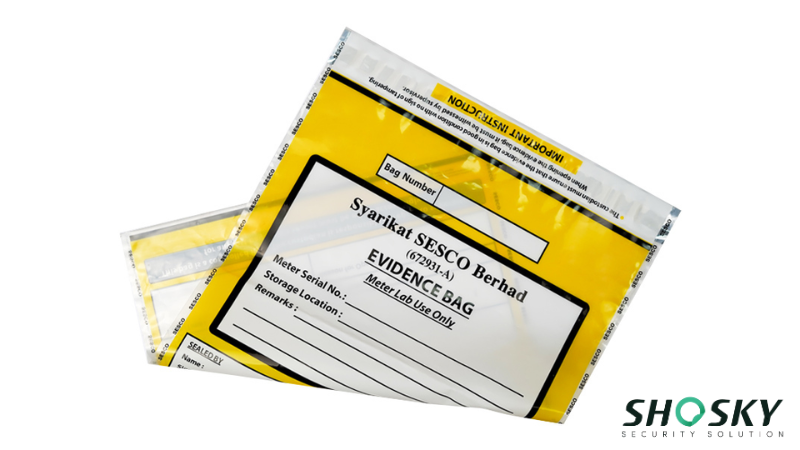

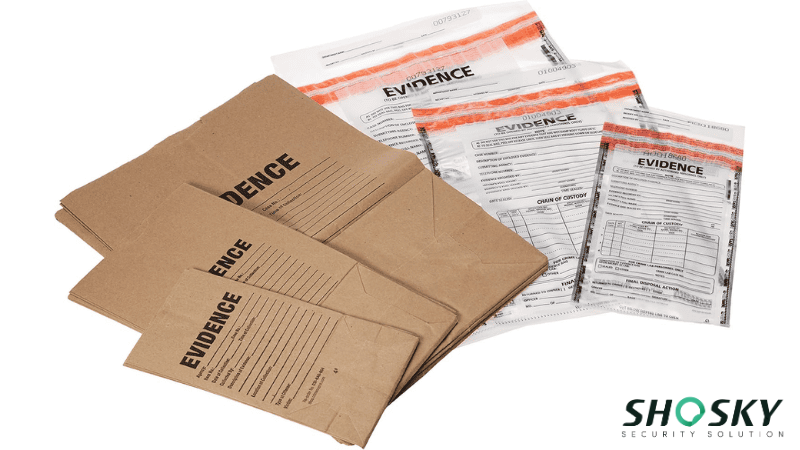

1. Tamper-Evident Bags

Tamper-evident bags are specially designed packaging bags that reveal visible signs of tampering once opened. They are made from strong, durable materials such as polyethylene and often feature irreversible closures like permanent adhesive strips, security seals, or void tapes.

Once the bag is sealed, any unauthorized attempt to open it will cause noticeable damage, such as tearing, permanent adhesive residue, or a “VOID” message being displayed. Some versions also include serial numbers or barcodes to enhance traceability and prevent substitution or replication.

These bags are widely used in industries where secure handling is essential, such as banking (cash deposit bags), medical specimen transport, forensic evidence collection, retail, and e-commerce returns.

Pros

- High tamper visibility

- Lightweight and easy to handle

- Available with various security levels and features

Cons

- Single-use only

- Can be punctured or slashed if not reinforced

- Environmental concerns due to plastic materials

2. Tamper-Evident Tapes

Tamper-evident tapes are special adhesive sealing tapes used to package goods. Unlike them, they use pressure-sensitive adhesives that bond firmly to the application surface. Some tapes also have unique serial numbers or QR (Quick Response) codes printed upon them, making replication difficult.

If someone tries to open, remove, or alter the packaging, the tamper-evident tape may cause irreversible damage to the surface it was applied to, such as adhesive residue or torn materials. Some partial-transfer tape patterns or messages, such as “VOID” or “OPENED,” become visible if the tape is lifted.

Unlike labels, which only indicate tampering, tamper-evident tapes both seal and secure packages. The uses of tamper-evident tapes include shipping packages, high-value cargo, e-commerce, and logistics. They are also used for medical devices and sensitive electronics to ensure the product reaches the customer safely.

Pros

- Immediate indication of tampering

- Customization options (logos, barcodes, holograms, etc.)

- Low-cost

Cons

- Only effective for flat or smooth surfaces

- Can be duplicated

- Single-use only

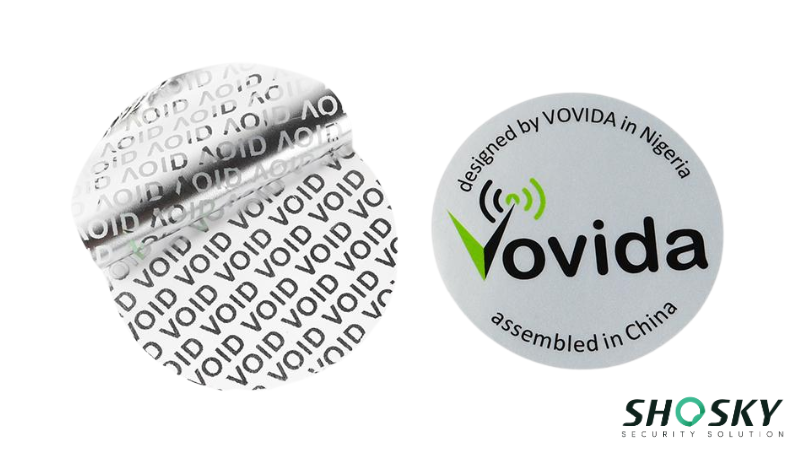

3. Labels and Stickers

Tamper-evident packaging can also include unique labels or stickers. If disturbed, these can tear, leave residue, or distort the labels, making it evident to the consumer that the product has been tampered with.

These include void labels that leave a “VOID” imprint when peeled or destructible stickers that break apart or get torn upon removal. They can also include holographic labels incorporating unique labels that are nearly impossible to replicate.

Most common applications include pharmaceuticals, toys, warranty seals on electronics, and retail consumer products.

Pros

- Cost-effective

- Customizable

- Simple to apply

Cons

- Easily bypassable by skilled tampering

- Easy to replicate

- Short lifespan

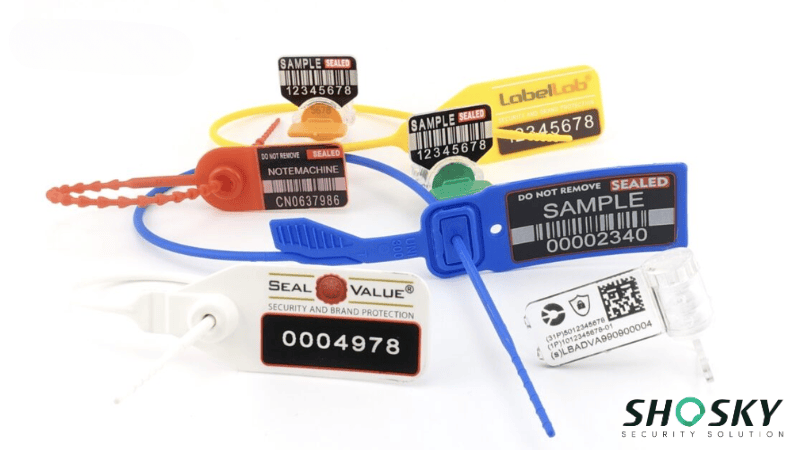

4. Security Seals

Security seals are locking devices that show visible signs of tampering if removed or broken. They come in various types, such as cable seals, bolt seals, and plastic pull-tight seals.

Each seal often includes a unique serial number, barcode, or QR code for traceability and verification. Once broken, these seals cannot be reused or replaced without detection.

Security seals are widely used in logistics, cargo containers, meter boxes, ballot boxes, and airline catering.

Pros

- Strong visual tamper indicators

- Range of strength and security levels

- Trackable via serial codes

Cons

- Not suitable for small packaging

- Single-use

- May require tools for removal

5. Shrink Bands and Seals

Shrink bands and seals are made from plastic that shrinks around the product caps, lids, or body when heat is applied. They form a very tight seal around the container, making it extremely difficult to open without damaging the seal.

If breached, the shrink band tears apart while the adhesive marks or distortions become apparent in the case of a tamper-evident seal. These damages to the band or seal provide consumers with the information that the product has been tampered with.

This type of tamper-evident packaging is most effective for medicine bottles, food containers, beverage bottles, body lotion bottles, serums, and cleaning liquids. Shrink bands and seals can be printed with the company name, safety messages, or directions for opening the seal.

Pros

- Immediate tamper detection

- Easy to use

- Available in multiple colors

- Cost-effective

Cons

- Contributes to environmental pollution

- Requires heat for sealing

- Cannot combat skilled tampering attempts

6. Breakable Closures

As the name suggests, breakable closures are designed in a way that any attempt to tamper can cause the closure to break or deform physically, leaving clear visual evidence of interference. The irreversible breakage makes it impossible to restore its original form.

Modern closures are designed with recyclable or biodegradable materials, which can minimize environmental impact. Innovations in eco-friendly adhesives and inks ensure the tamper-evident nature of packaging is maintained without compromising sustainability.

Breakable closures are commonly used in industries where the integrity of the product directly affects the health and safety of consumers, such as pill bottles, syrups, juice bottles, milk cartons, and sensitive chemicals.

Pros

- Protects from product pilfering or tampering

- Difficult to reseal or repair the closure after opening

- Cost-effective

Cons

- One-time usage

- Risk of product contamination after opening

- Complicated for some consumers to open

7. Blister Packs

Blister packs consist of a cavity of transparent plastic and a backing sheet (often aluminum foil). They are used for single items like capsules or small electronic items. The transparent cover allows consumers to visually inspect the product inside, and the backing confirms that the product is secure.

If a blister pack is breached, it will be damaged physically. This way, consumers can quickly identify that the product has been tampered with. Blister packs also allow easy removal of an individual item while keeping the rest of the product sealed.

The blister pack design supports printing serial numbers, labels, expiry dates, or barcodes directly on the packaging. The most common use cases include tablets, batteries, or single-dose condiments.

Pros

- Unit-dose packaging

- Protection from moisture or contamination

- Customized designs

Cons

- Contributes to environmental waste

- Manufacturing is expensive

- Not suitable for large items

8. Sealed Clamshell Packaging

This type of packaging consists of two hard plastic shells sealed together by heat. Because one can’t open the packaging without cutting it, any manipulation is visible. Sealed clamshells also deter package pilferage.

Once tampered with, a sealed clamshell package cannot be resealed without obvious alterations. Another key advantage is the transparent design, which allows customers to view the product without opening it to ensure product quality.

Sealed clamshell packaging is widely used for toys, batteries, razors, electronic gadgets, chargers, and more. Some sealed clamshells have both ultrasonic and heat sealing, which makes them more tamper-resistant and tamper-evident.

Pros

- High tamper-resistance

- No product size limitations

- Transparency

Cons

- Difficult to open for consumers

- No reusability

- Environmental concerns

9. Vacuum Sealed Packaging

Next on the list is vacuum-sealed packaging, which involves sealing a package after removing all the air from the inside and creating an airtight and secure seal. This type of packaging solution is mainly used to extend the shelf life of products and protect them from external factors.

The tamper-evident nature of this packaging provides very noticeable changes in the package’s appearance upon any tampering. Exposure to air can lead to spoilage, decoloration, or corrosion of the product.

Due to its ability to prevent contamination by eliminating exposure to air or moisture, it is most suitable for perishable items, sensitive products, and sterile medical equipment.

Pros

- Extended shelf life

- Maintains product integrity and freshness

- Versatile usage

Cons

- Requires specialized machinery

- No reusability

- Use of non-biodegradable plastics

10. Multi-layer Film Packaging

Lastly, we have multi-layer packaging made from different layers of plastic and aluminum. These materials result in a strong, protective barrier against moisture, air, and UV light. The films are typically thin and transparent, allowing customers to visually inspect the item inside.

Any tampering in multi-layer film packaging is easily detectable. There are visible signs of damage, including torn film, broken seals, or deformed packaging, alerting the customer that the product is no longer safe to use.

Multi-layer film packaging is used for food packaging, such as snacks, frozen items, and pre-packaged meals. It is also used for cosmetics, medicines, and electronics.

Pros

- Lightweight

- Cost-effective

- Strong protection against contaminants

Cons

- Costly manufacturing requirements

- Harmful to the environment

- Limited Strength

Tamper-Evident vs. Tamper-Resistant vs. Tamper-Proof

According to the Food and Drug Administration(FDA), tamper-evident packaging indicates if the product has been opened or altered before reaching the end user. This type of packaging ensures product integrity and alerts consumers if a security breach occurs.

However, many confuse tamper-evident packaging with tamper-resistant packaging or tamper-proof packaging. These three terms are often used interchangeably, but they describe different levels of protection.

Understanding their distinctions helps businesses choose the right solution based on the product’s risk level and security needs.

Tamper-Evident Packaging

Tamper-evident packaging is designed to show clear signs if someone tries to open, alter, or interfere with the product.

It doesn’t stop access but makes tampering immediately visible. Examples include security tapes that leave “VOID” messages, shrink bands around bottle caps, and seals that break once opened. This type is commonly used in pharmaceuticals, food, and consumer goods to maintain customer trust.

Tamper-Resistant Packaging

Tamper-resistant packaging makes it difficult to open or alter the product without tools or noticeable damage. The goal is to discourage tampering rather than make it impossible.

It’s often used for electronics, cosmetics, and over-the-counter medications. While it slows down unauthorized access, it may not always reveal tampering as clearly as tamper-evident options.

Tamper-Proof Packaging

Tamper-proof packaging offers the highest level of protection. It’s designed to prevent tampering altogether. Once sealed, it cannot be opened or resealed without breaking the package entirely. This option is typically reserved for high-value or highly sensitive items such as medical equipment, forensic evidence, and government documents.

In short, tamper-evident solutions signal interference, tamper-resistant ones discourage it, and tamper-proof systems aim to eliminate it. The right choice depends on the level of risk, compliance needs, and how critical product integrity is to your operation.

Key Benefits of Using Tamper-Evident Packaging

Tamper-evident packaging offers several advantages regarding safety, security, and efficiency. Here are a few key benefits that make this type of packaging a preferred choice for businesses across many industries.

1. Customer Confidence

Tamper-evident packaging builds trust in both the product and brand by assuring customers that the item they are purchasing has not been compromised. Tamper evidence solutions, such as broken seals or broken lidding films, provide visible evidence of tampering, giving customers a clear indication of potential issues.

2. Fraud Prevention

One key advantage of a tamper-evident package is its ability to reveal unauthorized access, making it difficult for fraudsters to engage in product pilfering or to alter the product’s contents without leaving clear visual evidence. This tamper evidence not only ensures consumer safety but also helps build brand loyalty.

3. Compliance with Safety Standards

Regulatory bodies like the FDA require tamper-evident packaging for certain consumer goods, such as pharmaceuticals and food. Compliance with safety standards confirms that the brand is committed to protecting consumers and maintaining customer loyalty.

4. Reduced Environmental Exposure

Tamper-evident seals help maintain product quality by protecting the contents from environmental exposure, which can indirectly increase shelf life. For products such as eye droppers, essential oil containers, food items, and beverage bottles, this added layer of protection helps preserve freshness and builds consumer confidence.

5. Efficient Risk Control

Businesses can prevent problems by early detection of tamper evidence. Evidence of tampering can help them identify and isolate altered products on time, saving them from more significant issues such as widespread recalls or costly legal consequences and ensuring a secure and efficient supply chain.

How to Select the Right Tamper-Evident Packaging for Your Needs?

Choosing the right tamper-evident packaging solution can be challenging. The process involves evaluating factors specific to your product, market requirements, and regulatory standards. Here is a brief guide to help you choose the most appropriate type.

The table below provides a quick comparison of common tamper-evident packaging options and their typical applications. Use it as a reference point when shortlisting what fits your business best.

Tamper-Evident Packaging Type Most Common Industry Use Cases

Tamper-Evident Bags Banking, e-commerce, medical labs, forensic investigations

Tamper-Evident Tapes Logistics, electronics, medical devices, retail packaging

Labels and Stickers Pharmaceuticals, warranty seals, toys, cosmetics

Shrink Bands and Seals Beverage bottles, food containers, personal care, supplements

Breakable Closures Pharmaceuticals, dairy products, chemical containers

Blister Packs Pharmaceuticals, electronics, single-use food condiments

Sealed Clamshell Packaging Consumer electronics, tools, toys, cosmetics

Vacuum Sealed Packaging Food industry, medical tools, electronics, industrial components

Induction Seals Health supplements, beverages, chemical jars

Holographic Seals Luxury goods, pharmaceuticals, electronics, official documents

Once you’ve reviewed the options, the next step is to evaluate a few key factors that help narrow your selection. The following considerations can guide you in choosing packaging that not only meets your security needs but also aligns with your brand and operational goals.

Categorize the Product Type

Different types of products can have different packaging requirements. For example, liquids and beverages have a risk of leakage, so shrink bands and induction seals can be considered. Pharmaceuticals need sterility, so blister packs would be more appropriate.

Check Regulatory Standards

Different industries have different legal and regulatory standards for packaging, so it is crucial to research the standards in your industry. Some popular regulatory bodies include the FDA, OSHA (Occupational Safety and Health Administration), and EFSA (European Food Safety Authority).

Analyze Cost Parameters

Analyze and compare the expenditures for all tamper-evident packaging solutions suitable for your product. Make an estimated cost breakdown for all costs, including material, manufacturing, design, and tooling costs.

Test the Design

Test the packaging for functionality, reliability, and durability. Test the packaged product under high temperatures, chemical exposure, or UV light conditions to confirm if it withstands extreme conditions and maintains tamper-evident features. Some manufacturers even offer free samples so you can test the packaging before making a decision.

Assess Customer Experience

Assessing customer experience can include factors like usability, security, and satisfaction. Feedback and iterative improvements can help you choose the perfect tamper-evident packaging for your product.

Future Of Tamper-Evident Packaging

The global tamper-evident packaging market was valued at $2.2 billion in 2023. With a CAGR(Compound Annual Growth Rate) of 8.5%, it is expected to reach $4 billion by 2032. This growth results from increasing consumer safety concerns and awareness, driving demand for more secure solutions.

Practices such as using biodegradable, sustainable, and recyclable materials have recently changed the packaging landscape.

Additionally, smart packaging solutions, such as RFID (Radio Frequency Identification) tags, sensors, and QR codes, make real-time monitoring of products easier and provide better security against tampering.

FAQs

Q1: Are tamper-evident seals customizable?

Yes, tamper-evident seals can be customized with logos, serial numbers, barcodes, or safety messages.

Q2: How can tamper-evident packaging increase consumer confidence?

By providing visible evidence of tampering, consumers are reassured that the product they are purchasing is safe and has not been altered.

Q3: Which industries commonly use tamper-evident packaging?

Industries such as food and beverage, pharmaceuticals, electronics, cosmetics, and retail heavily rely on tamper-evident packaging.

Conclusion

Tamper-evident packaging is a critical investment in product safety and consumer confidence. These solutions provide visible evidence of interference, deterring tampering, and ensuring safety. With various options available, businesses can customize tamper-evident packaging to meet their specific needs, enhance security, and protect their brand reputation.

Get Reliable Tamper-Evident Packaging Solutions from Shosky Security

At Shosky Security, we provide premium, tailored, tamper-evident packaging solutions to meet diverse needs. Our comprehensive range of tamper-evident packaging includes security seals, perforated tamper-evident tapes with serial numbers imprinted, destructible labels, and more. Contact us now for expert guidance and product details.