The worldwide market for security labels has surpassed $8.2 billion and shows no signs of slowing down. More and more businesses are turning to tamper-evident packaging solutions to protect their products. As a result, the demand for tamper-evident features enriched security labels is at an all-time high.

And that’s where the paper vs. plastic question gets tricky. While paper security labels may align better with composting systems and renewable resources, plastic labels offer tamper evidence that’s hard to beat. So, which option wins out? Let’s have a look at that in this detailed article.

What Are Security Labels and Why Are They Used?

Security labels are a category of labels designed to reveal tampering, prevent unauthorized access, and confirm authenticity. They do this by using special materials or adhesives that break, leave residue, or display warning messages when removed. Some also use codes or embedded data for traceability.

These labels support anti-theft systems, help detect tamper-proof packaging breaches, and play a key role in verifying that goods are untouched from factory to shelf. In regulated industries, they also meet traceability and safety requirements.

Many businesses now include security labels as part of broader packaging solutions that reduce risk and improve logistics.

In fact, with rising interest in sustainable and compostable packaging, brands are now looking for manufacturers who create labels that balance product protection with environmental responsibility.

You’ll find these labels used in:

- Pharmaceutical packaging to track distribution and ensure authenticity

- Electronics to prevent tampering or return fraud

- Food packaging, especially where compostable food service containers are used

- Cosmetics, where brand safety and hygiene are top concerns

As demand for eco-conscious products grows, some brands are moving toward sustainable labels that use recycled paper or work with label backing liners that don’t harm composting or recycling streams. The shift is also driven by concerns about harmful chemicals in traditional plastic-based options.

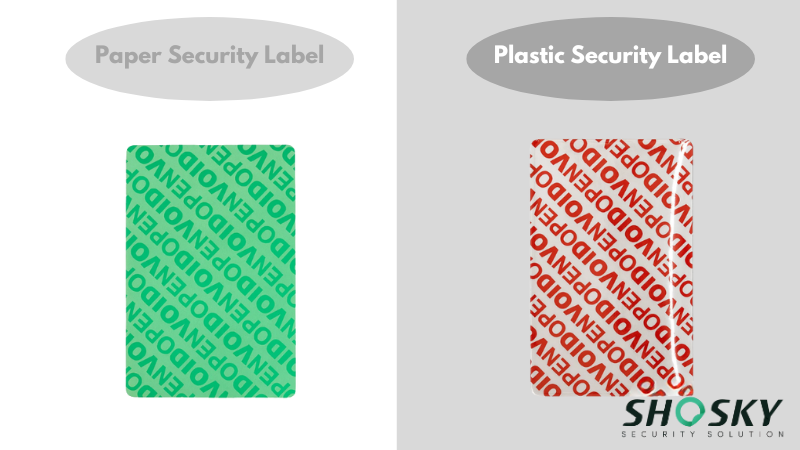

Paper Security Labels – Features and Benefits

Security labels made from paper offer more than just product protection. They can meet both safety and sustainability needs, especially for companies aiming to reduce plastic use. Paper labels are often chosen for their print flexibility, compostable material options, and lower environmental impact compared to plastic ones.

Below is a breakdown of key features and how they benefit your packaging.

- Tamper-Evident Design: Shows clear signs of removal or damage, making it easy to detect tampering and protect product integrity.

- Custom Serial Numbers: Each label can carry a unique ID for better traceability, helping with audits, recalls, and inventory checks.

- Security Printing: Includes options like UV ink or microtext to prevent counterfeiting and protect against forgery.

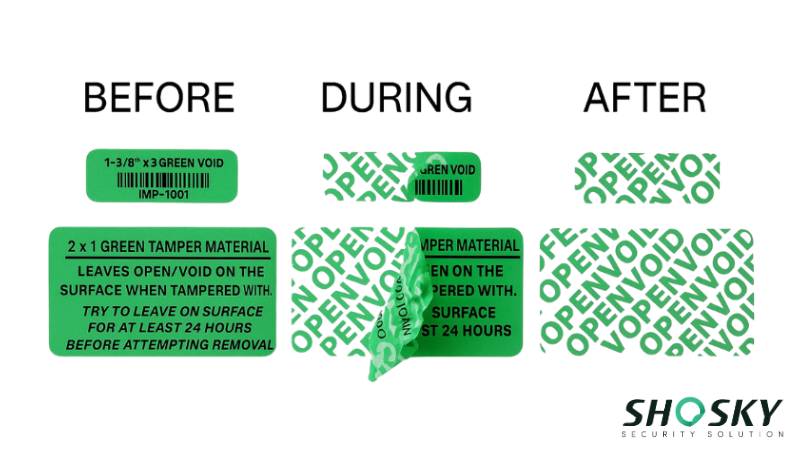

- Void Message Reveal: Displays a “VOID” message when peeled off, signaling unauthorized access right away.

- Eco-Friendly Material: Made from biodegradable or recyclable paper, reducing plastic use and supporting greener packaging goals.

Paper security labels are especially suitable for dry goods, retail packaging, and brands focused on eco-conscious practices.

They work well with recyclable materials, pair easily with sustainable packaging, and provide reliable tamper evidence without relying on plastic. This makes them a smart choice for many applications, without compromising on trust or sustainability.

Plastic Security Labels – Features and Benefits

Plastic security labels are built for durability and performance. They’re a go-to choice for products that need long-term protection, exposure to rough conditions, or more advanced tamper-evident features. Often used in industries like pharma, logistics, and electronics, plastic labels offer strength where paper can’t.

Below is a breakdown of their main features and how they help protect your products.

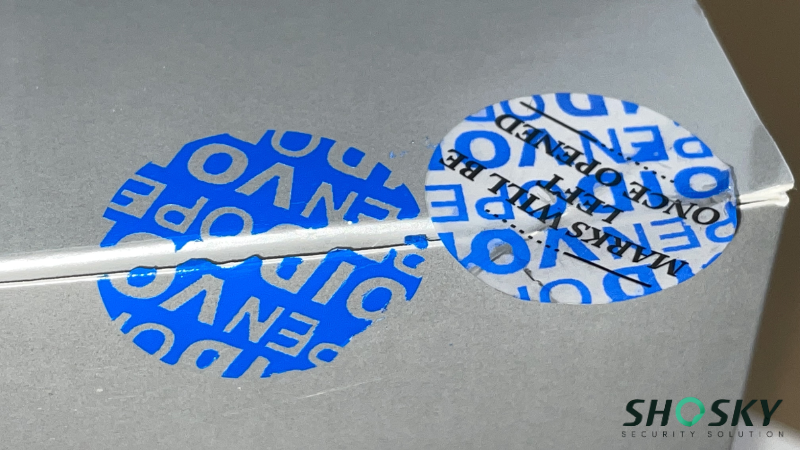

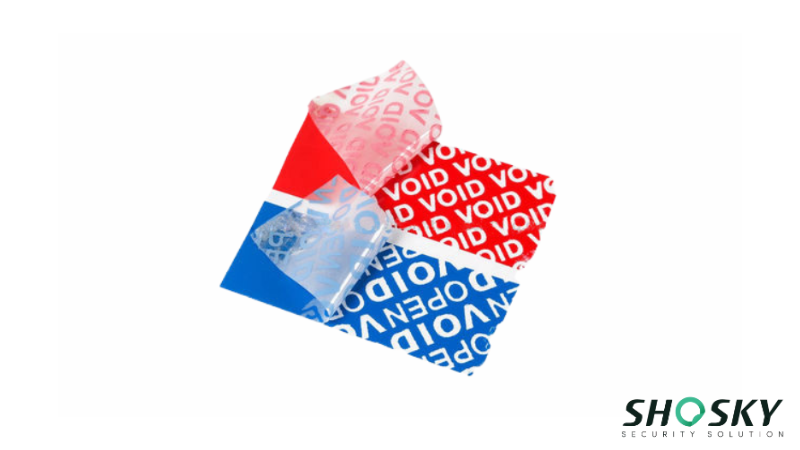

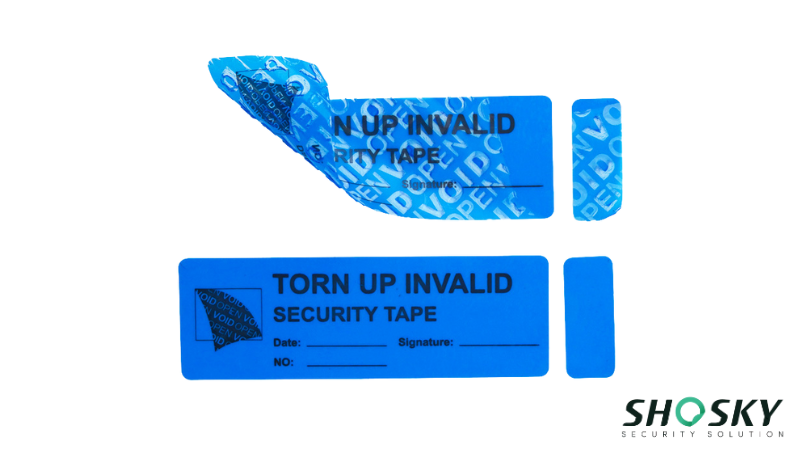

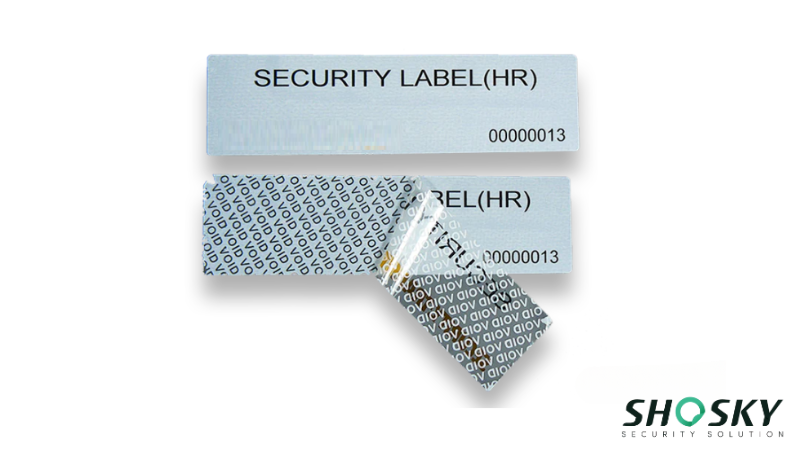

- Tamper-Evident Surface: Breaks or leaves marks if tampered with, making it hard to reuse or reseal the packaging unnoticed.

- Weather Resistance: Stays intact through heat, cold, and moisture, making it ideal for transport, outdoor use, or storage.

- Advanced Security Printing: Supports holograms and UV features that strengthen protection against fakes and tampering.

- Void Film Activation: Reveals hidden warnings like “VOID” once removed, offering strong visual proof of interference.

- Smart Tech Compatibility: Works with RFID tags, QR codes, and other tracking systems for enhanced supply chain visibility.

Plastic security labels are best for tough conditions and long-term use. While they may not be compostable, they’re ideal where security, durability, and advanced features are the priority.

They support high-risk packaging, improve supply chain visibility, and help brands maintain trust, especially in regulated sectors.

Environmental Impact of Labeling Solutions: Material Comparison

With more companies leaning into sustainable packaging, the label material matters just as much as the product wrap itself. Paper and plastic labels both offer functional benefits, but their environmental effects are very different. Here’s how they compare in key areas:

| Factor | Paper Security Labels | Plastic Security Labels |

|---|---|---|

| Biodegradability | Breaks down quickly, especially in compost setups | Not biodegradable; remains in landfills or oceans |

| Recyclability | Widely recyclable with common materials | Needs special processing; often ends up as waste |

| Carbon Footprint | Lower if sourced from renewable materials | Higher due to petroleum-based production |

| Disposal Issues | Compatible with compostable and recyclable systems | Can contaminate recycling or compost streams |

| Innovation Potential | Easily adapted to new eco-friendly adhesives | New compostable plastics exist, but aren't common |

Despite progress in label design, disposal remains a challenge. To avoid harmful chemicals and reduce waste, companies should explore sustainable labels and test how their materials perform in composting systems or recycling channels. Small changes here can lead to a lower environmental impact across your entire packaging solution.

A 2024 life cycle assessment comparing plastic RFID tags to paper‑based equivalents found that paper tags cut greenhouse gas emissions by up to 23%, reducing global-warming impact significantly. That shows how paper alternatives can offer real environmental benefits.

Performance Analysis of Packaging Solutions: Different Use Cases

Understanding how each material performs under real-world conditions helps narrow down your options. From durability to tamper evidence and surface compatibility, here’s how paper and plastic labels hold up in different use cases.

Durability and Resistance

Plastic security labels show strong heat resistance, withstanding temperatures over 150°F without warping or losing adhesion. Paper labels start to weaken at around 120°F, especially in humid or high-pressure settings.

For packaging solutions exposed to hot environments, like transport in direct sunlight or heated storage, plastic is often more reliable.

When it comes to moisture, plastic outperforms paper by a wide margin. Plastic absorbs less than 0.1% moisture, keeping the label intact and legible.

In contrast, paper labels may soak up 8–12% moisture, which weakens the adhesive and can blur text. For cold-chain or damp conditions, plastic packaging labels are a better option.

Durability in handling tests reveals even bigger differences. Plastic labels remain intact for over 1,000 flex or rub cycles, while paper shows damage after about 100 cycles. For products that require frequent handling, scanning, or shipping, plastic labels avoid early wear and help maintain a professional look.

Tamper Evidence Technology Integration

Security and tamper-technology layers behave differently depending on the label material.

Plastic allows advanced VOID-style, holographic effects, and layered features thanks to its smooth surface. Paper labels offer visible tear patterns that show tampering but lack the precision and complexity of plastic.

Material choice impacts how well each labeling solution works as part of the whole package.

While basic pre-printed security features function on both materials, intricate designs often lean on plastic’s stability. When choosing between labels, brands should match the feature design to both the material and expected use.

Each individual component – adhesive, face material, or liner – affects the final performance.

The paper offers eco-friendly options with compostable adhesives that support sustainability goals. Plastic provides strong bonding and advanced security, but requires careful recycling planning to avoid compost contamination or waste.

Application Surface Compatibility

Paper labels work best on textured or porous surfaces like cardboard, kraft, or compostable food service containers. Their natural fibers help adhesives grip paper fibers well, making them ideal for dry, recyclable packaging. For eco-friendly brands seeking biodegradable packaging options, paper remains a top choice.

Plastic labels are better suited for smooth, non-porous surfaces such as metal, glass, and plastic packaging. They conform to curved bottles or tubes with minimal wrinkles and avoid peeling under cold or wet conditions. In cold storage or humid transport, their adhesive holds tight without failing.

Choosing the right label means matching the material to both surface and environment. For indoor, dry conditions, paper works well. But when protection against moisture, bending, or low temperatures is needed, plastic labels keep products secure and intact, helping brands stay professional across different handling scenarios.

Factors to Consider When Selecting the Right Security Label Material

Selecting the right material for your security labels isn’t always a one-size-fits-all decision. Each product comes with its own handling, storage, and compliance needs.

Whether you’re packaging food, shipping electronics, or selling eco-friendly goods, your material choice should support both performance and sustainability. Below, we break down three key factors that can guide you toward the best fit.

Factor 1: Match Materials to Application Needs

When deciding between paper vs plastic security labels, consider these factors:

- Product environment – indoor/dry vs outdoor/wet

- Security feature needs – simple destructible vs advanced VOID/holograms

- Sustainability goals – prioritize lower environmental impact or durability

- Compliance standards – e.g., composting standards, circular economy mandates

For eco‑friendly brands like organic skincare or bulk grocery, paper labels with compostable adhesives and industrial composting compatibility often work best. For medical, electronics, or logistics with strict hygiene needs, plastic labels deliver the performance required.

Factor 2: Balance Costs, Storage, and Bulk Orders

Paper labels often cost less per unit but require higher inventory space and may have a higher weight. Plastic labels are lightweight and compact, ideal for bulk, especially when looking at bulk discounts and custom pack size orders.

- Paper labels: lower material cost, but possibly higher minimum purchase limits.

- Plastic labels: efficient shipping, lower per‐label cost at high volume.

- Bulk buyers must consider labeling solution costs, adhesive type, transport weight, and storage.

These cost factors depend on expected use, product safety needs, and whether you seek recycled or compostable materials.

A 2022 report from the European Label Institute found that orders under 10,000 labels of any material saw a 15–25% price increase compared to larger batches. That shows how economies of scale affect per‑unit cost – keeping storage efficiency and bulk pricing front of mind can make a big difference.

Factor 3: Stay aligned with Regulatory & Compliance

When choosing labels, check that the material meets relevant composting standards or regulatory guidelines.

Paper often fits circular economy frameworks, renewable resources, and eco-friendly materials criteria.

Plastic labels may require recommended testing to ensure compliance for food packaging or pharmaceuticals.

Consider:

- Is the adhesive FDA-approved for food packaging?

- Does the label back liner contaminate recycling systems?

- Are labels pre-printed with necessary traceability or serialization?

These factors influence valid customer acceptance and meeting sustainability certification.

FAQs

Are paper security labels waterproof?

Not typically. Some coatings can improve resistance, but plastic is better for moisture-heavy environments.

Can paper security labels include VOID features?

Yes, but with less precision than plastic. They’re better for destructible or frangible designs.

Are there 100% plastic-free tamper-evident labels?

Yes, there are many more sustainable packaging options made from compostable paper and natural adhesives – ideal for eco brands.

Conclusion

Both paper and plastic security labels serve important roles across industries. The right choice depends on your product’s handling, environmental exposure, and labeling needs. Paper fits best for dry retail or eco-focused items, while plastic works better for industrial or regulated environments. Still unsure which tamper-evident solution is right for your product? Let us help you find the perfect match!

Find the Best Fit: Paper vs Plastic Security Labels with Shosky Security

At Shosky Security, we offer both paper and plastic labeling solutions of different sizes tailored to your industry, product consumers, and compliance needs. Get in touch today to explore our custom tamper-evident label options or request a free quote to see how