Counterfeit medicines are a silent crisis in the global healthcare system. According to the World Health Organization (WHO), approximately 1 in 10 medical products in low- and middle-income countries is substandard or falsified.

This is why regulatory bodies worldwide have stepped in. From the Falsified Medicines Directive (FMD) in Europe to the Drug Supply Chain Security Act (DSCSA) in the United States, the message is clear. Pharmaceutical packaging must be tamper-evident. In this guide, we will explore how tamper-evident pharmaceutical labels serve as the frontline defense for your products to help you choose the right solution for your products.

Why Pharmaceutical Packaging Compliance Needs Destructible Labels?

Compliance is the primary driver for packaging changes in the pharma industry. Regulations like ISO 21976 require medicinal products to have an “anti-tampering device” on the outer packaging.

Ultra destructible labels for medicine are widely considered the most efficient way to meet these standards. Unlike shrink wrap, which requires expensive machinery changes, a pressure-sensitive security label can be applied using standard labeling equipment. Beyond compliance, these labels offer three critical business advantages:

- Visual Assurance: Patients can instantly verify if the seal is intact before purchase.

- Liability Protection: A broken seal shifts responsibility away from the manufacturer if the contents are altered.

- Brand Integrity: High-quality security seals signal that the product inside is genuine and premium.

These advantages make destructible labels not just a legal necessity, but a strategic investment in your brand’s longevity and consumer trust.

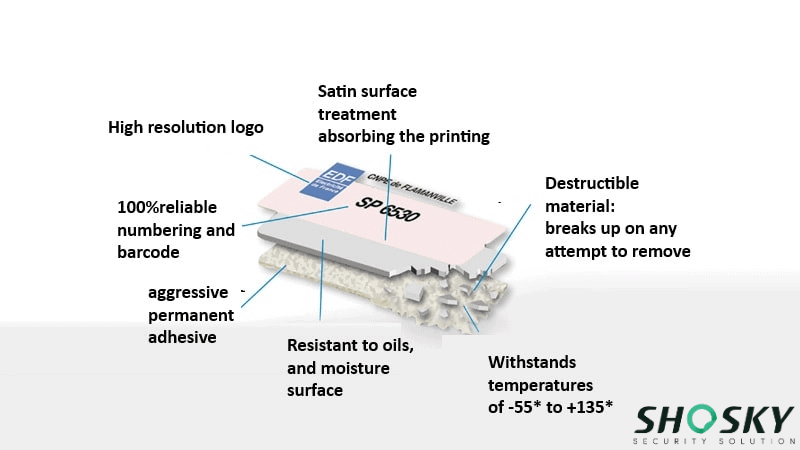

What Is an Ultra Destructible Label for Medicine?

You might be wondering what makes these labels different from the stickers you see on a fruit or a notebook. Standard labels are made of durable paper or film that can be peeled off and often re-applied. This represents a massive security risk in the medical field.

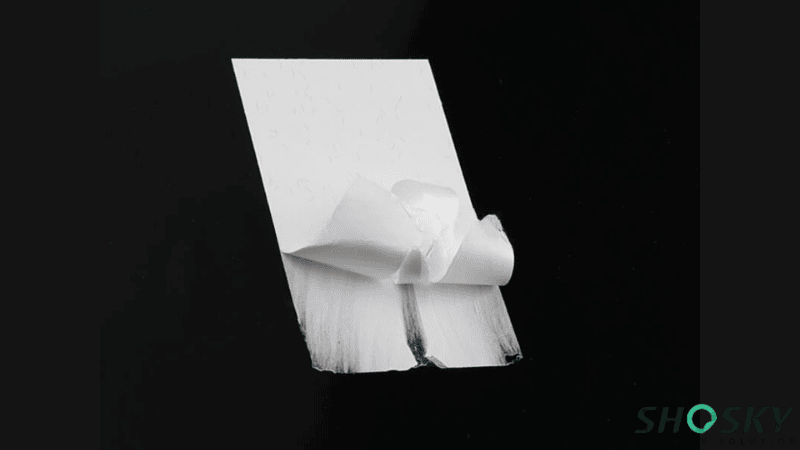

Tamper-evident labels, an ultra-destructible label, operate on a deliberate imbalance of forces. It relies on a property known as ‘frangibility.’ The physics are simple yet effective: the tensile strength of the face material is significantly lower than the bond strength of the adhesive. This means the label is physically incapable of withstanding the force required to peel it off.

When someone attempts to peel this label off a medicine carton or bottle, the bond between the adhesive and the packaging is stronger than the label material itself. The result is immediate fragmentation. The label shatters into tiny, eggshell-like pieces that cannot be put back together. This irreversible damage provides forensic evidence of tampering that is impossible to hide.

Comparing Destructible Label Materials for Pharma Applications

Not all destructible labels are created equal. A label that works perfectly on a flat cardboard box might fail miserably on a small glass vial with a tight curve. Choosing the right tamper-evident pharmaceutical labels depends on your specific packaging substrate.

To help you navigate the options, we have created this material selection matrix. Use this to match your packaging type with the correct security label:

| Label Material Type | Best Surface Application | Key Technical Advantage | Frangibility Level |

|---|---|---|---|

| Foamtac (Foam Vinyl) | Small Diameter Bottles, Vials, Syringes | Flexible; No edge lifting on curves; Layers separate upon removal. | High |

| Destructible Synthetic Paper | Flat Cardboard Cartons, Large Bottles | Smooth Printing Surface; Excellent for barcoding; Tears paper fibers. | Medium-High |

| Holographic Destructible | High-Value Boxes, Biologics | Visual Authentication; Prevents copying; Combines branding with security. | High |

| Clear VOID Seal | Printed Retail Boxes | Transparent; Does not obscure branding text; Leaves "VOID" residue. | N/A (Residue based) |

Selecting the right material from this table ensures that your security label survives the supply chain while failing precisely when attacked. Now, let’s dive into this part.

Foamtac Destructible Label Material

For many pharmaceutical applications, Foamtac is the superior choice. It is a unique, destructible vinyl with a foam-like, layered structure that solves the problem of labels lifting off surfaces.

Key Features:

- Zero Memory Effect: It does not try to “flatten out,” meaning it won’t lift off the edges of curved bottles.

- Layered Destruction: When tampered with, it separates into layers like a delaminating sponge.

- Soft Texture: It conforms perfectly to small diameters like test tubes and syringes.

This combination of features makes Foamtac the industry standard for securing small, high-value vials that require absolute seal integrity.

Co-extruded Destructible Synthetic Paper

Co-extruded, destructible synthetic paper is made from PP synthetic paper, the workhorse for sealing standard paper cartons. It is slightly stiffer than foam, which gives it a smoother surface finish ideal for high-resolution printing. It is a cost-effective solution for outer packaging where the surface is flat.

Key Features:

- Superior Printability: The smooth face stock is perfect for printing sharp barcodes, serial numbers, and small regulatory text.

- Fiber-Tear Bond: The adhesive is formulated to aggressively bite into paperboard, tearing the box fibers upon removal.

- Cost Efficiency: It offers a lower price point compared to foam or holographic options, making it suitable for high-volume runs.

For manufacturers sealing thousands of outer cartons daily, this material provides the perfect balance of security, print quality, and budget.

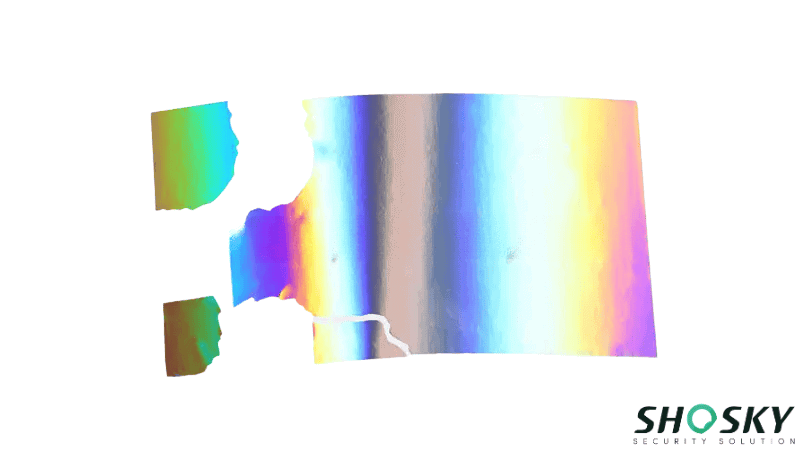

Holographic Ultra Destructible Label Material

If you want to combine security with brand protection, holographic ultra-destructible label material is the answer. This material uses tough vinyl with a shiny holographic layer. This makes them both attractive and secure.

Key Features:

- Tamper Evidence: The destructible nature prevents the package from being opened without damage.

- Anti-Copying: The complex custom hologram is extremely difficult for counterfeiters to replicate.

- Visual Appeal: The shiny finish signals a premium product, enhancing shelf appeal.

By integrating optical security with physical fragility, these labels offer a double layer of defense against sophisticated counterfeiting rings.

Advanced Anti-Counterfeit Drug Packaging Features

Modern tamper-evident pharmaceutical labels can be smart as well as strong. Integrating technology into your labels transforms them from a passive seal into an active data carrier.

1. Serialization and Track & Trace

Supply chain transparency is vital. Destructible labels can be printed with variable data, such as unique serial numbers, QR codes, or Data Matrix codes. This allows you to track individual units from the factory to the pharmacy. Because the code is printed on destructible material, it cannot be transferred to a fake product.

2. UV Invisible Inks

For an extra layer of hidden security, Shosky can print invisible markings with UV invisible ink that only show up under UV light. This is a powerful tool for your internal quality control teams to spot fake products quickly without alerting the counterfeiters.

3. Micro-Text Printing

This involves printing extremely small text that looks like a solid line to the naked eye but is readable under magnification. Standard photocopiers or digital printers cannot reproduce this level of detail. Adding micro-text to your destructible label makes it nearly impossible for counterfeiters to clone your packaging design accurately.

By layering these covert and digital features onto your physical labels, you create a “smart” packaging system that is exponentially harder for criminals to defeat.

Application Scenarios: Where to Use Tamper-Evident Pharmaceutical Labels

Effective security requires placing the right label in the right spot. Here are the three most common application points for anti-counterfeit drug packaging.

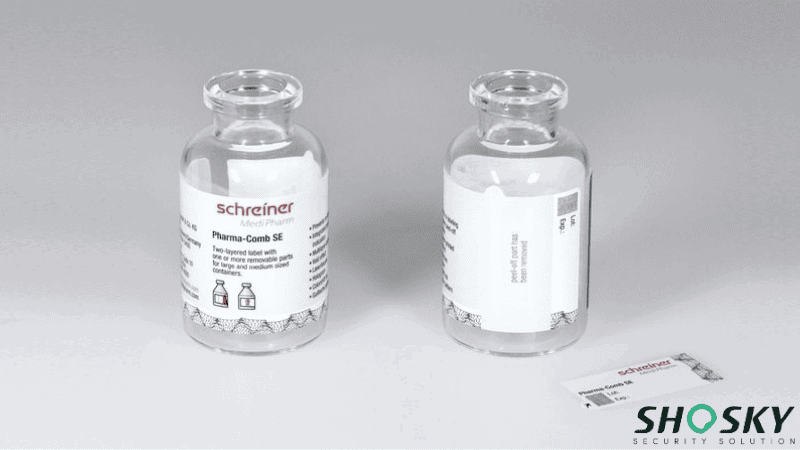

Sealing Small-Diameter Vials and Bottles

Small glass vials, test tubes, and eye drop bottles present a unique physics challenge known as the “memory effect.” Because the label is wrapped around a very tight curve (often less than 20mm in diameter), stiff materials naturally want to straighten back out. This causes the edges of standard labels to lift or “wing up” after a few weeks, creating a false impression of tampering.

For these applications, you must use Foamtac destructible label material. Its soft, foam-like structure has zero restoring force, meaning it stays wrapped tight around the cap and neck of the bottle indefinitely. It acts as a cap-to-body seal, effectively locking the closure system. This ensures that the rubber stopper or cap remains sterile and untouched until the patient opens it.

Securing Outer Cardboard Cartons

Most blister packs and injectable trays are sold inside a paperboard carton. Under regulations like the EU Falsified Medicines Directive (FMD), this outer carton must have a verification feature to prevent contents from being swapped. A clear or white ultra destructible label for medicine placed over the tuck flap is the industry standard solution.

However, thieves often use a technique called “steaming” to melt standard adhesive and peel stickers off without damage. To defeat this, our labels use a solvent-based acrylic adhesive that aggressively penetrates the paper fibers. If a thief tries to peel it, the label will not just break; it will tear the surface of the carton box itself (known as “fiber tear”), rendering the packaging visibly unsellable.

Sealing Plastic (HDPE/PP) Pill Containers

While glass and paper are easy to bond to, plastic containers present a different challenge. Most pill bottles for over-the-counter medicines or supplements are made from HDPE (High-Density Polyethylene) or PP (Polypropylene). These are known as “low surface energy” materials. In simple terms, these plastics are “slippery” to adhesives. A standard security label might sit on the surface without actually bonding, allowing a thief to peel it off cleanly after a few hours.

For these containers, you need a destructible label with a specially formulated high-tack rubber or hybrid adhesive. This adhesive is designed to “wet out” quickly on plastic surfaces, creating an instant, permanent bond. This ensures that even on a slippery plastic cap, the label will shatter immediately if someone tries to twist it open.

Case Studies: Preventing Medicine Tampering in the Supply Chain

Let us look at real-world examples of how medical safety with ultra-destructible label solutions works in the field.

The Dilution Scheme (Liquid Medicine)

A mid-sized pharmaceutical company exporting cough syrup found that distributors were heating and peeling standard paper seals to dilute the medicine before re-sealing it.

The Solution: The company switched to Shosky’s Foamtac destructible labels.

The Result: When thieves tried to heat and peel the new Foamtac labels, the material fractured into layers. It could not be removed in one piece. The visible damage made it impossible to resell the tampered bottles, forcing the criminal ring to stop targeting the brand.

The Gray Market Diversion (Vaccines)

A vaccine manufacturer found that subsidized products meant for Country A were being sold illegally at higher prices in Country B.

The Solution: They implemented Serialized Destructible Labels with unique QR codes on every box.

The Result: By scanning the codes on the diverted boxes, the manufacturer traced the leak back to a specific authorized distributor. Because the labels were destructible, the distributor could not remove the tracking codes without destroying the packaging. The manufacturer successfully closed the leak in their supply chain.

FAQs

Q1: Can ultra-destructible labels for medicine be applied by machine?

Yes, but tension settings must be adjusted. Materials like Foamtac are specifically designed to be stable on high-speed labeling lines.

Q2: Are these labels compliant with the EU Falsified Medicines Directive?

Yes. A high-quality destructible label that leaves visible evidence of opening satisfies the FMD requirement for an anti-tampering device.

Q3: Do these labels work on plastic and glass bottles?

Yes. Our adhesives are formulated to bond permanently to HDPE, PET, and glass surfaces.

Q4: Can I print variable QR codes on destructible materials?

Absolutely. Our labels are compatible with thermal transfer and UV inkjet printing for unique serial numbers.

Q5: What is the difference between “void” and “destructible” labels?

Void labels leave a text message (e.g., “VOID”) when peeled, but the film stays intact. Destructible labels shatter into pieces. Destructible is often preferred for pharma cartons as it offers higher security.

Conclusion

Ensuring medicine safety with ultra-destructible label solutions is not just about avoiding fines. It is about protecting the patients who rely on your products for their health. In a world where supply chains are complex and counterfeiting is sophisticated, a fragile label is your strongest defense.

Whether you need the flexibility of Foamtac for small vials or the optical security of holographic seals for high-value boxes, the right material makes all the difference. Don’t leave your packaging integrity to chance.

Improve Your Medicine Safety with Shosky Now!

Shosky Security specializes in advanced tamper-evident solutions. We specialize in anti-counterfeiting. This keeps your products safe and compliant with industry standards. Contact us today to find the best security labeling solution for your business!