Packaging security is more than just a precaution. It’s a legal requirement in many industries. Without tamper-evident solutions, products are vulnerable to counterfeiting and contamination. These risks can harm consumers and lead to serious legal consequences.

Legal consequences include heavy fines, product recalls, and lawsuits. So, businesses must follow these regulations to avoid penalties and protect their reputation. In this article, we will explore global compliance standards and how companies can meet them.

What Are Tamper-Evident Packaging Standards?

Tamper-evident packaging standards are regulatory guidelines. They define the required characteristics for secure product packaging. These standards establish benchmarks for detecting unauthorized access. And dictate the types of evidence that must be present.

In fact, these standards provide a framework for manufacturers. They outline the necessary measures for product safety. These measures might include security seals, security labels, and security tapes. The aim is to prevent counterfeiting and tampering from manufacturing to consumption.

Key Global Regulations and Standards

Tamper-Evident Packaging Standards: ISO 8317:2015

ISO 8317:2015 is an international standard for child-resistant and tamper-evident packaging. It sets guidelines for packaging that prevent unauthorized access while allowing easy use for adults. The standard applies to industries such as pharmaceuticals, chemicals, and household products.

To meet ISO 8317:2015 requirements, packaging must pass strict safety tests. These include evaluations for resealability and resistance to tampering. Compliance ensures product security and helps businesses meet international safety regulations.

U.S.: FDA & FSMA Regulations

The FDA (Food and Drug Administration) enforces strict tamper-evident packaging regulations. These rules apply to pharmaceuticals, food, and cosmetics. Packaging must include visible security features that indicate interference.

The FSMA (Food Safety Modernization Act) strengthens food packaging safety. It requires manufacturers to implement protective measures against contamination. Companies must use tamper-evident seals to comply with food safety laws.

EU: Falsified Medicines Directive (FMD)

The EU Falsified Medicines Directive (FMD) mandates tamper-evident packaging for pharmaceuticals. It aims to prevent counterfeit drugs from entering the supply chain. Packaging must include security seals and unique serial numbers.

Manufacturers must ensure that all prescription medicines have traceable safety features. The directive requires a standardized verification system. This helps pharmacies and consumers confirm a product’s authenticity.

ISO 17712: Tamper-Evident Seals in Logistics

ISO 17712 is the international standard for tamper-evident seals in shipping and logistics. It sets security requirements for container seals used in global trade. These seals prevent unauthorized access and protect goods during transportation.

To meet ISO 17712 compliance—seals must undergo strength and tamper resistance testing. High-security seals must meet strict design and durability standards. This ensures shipments remain secure throughout transit.

GMP: Good Manufacturing Practices

Good Manufacturing Practices (GMP) ensure packaging safety in the pharmaceutical industry. GMP guidelines require strict quality control during manufacturing. Companies must use validated tamper-evident packaging solutions. This helps protect consumers from counterfeit or unsafe products.

Regulatory agencies like the FDA, WHO (World Health Organization), and EMA (European Medicines Agency) enforce GMP standards. Non-compliance can lead to recalls, fines, and reputational damage. Businesses must follow GMP rules to ensure product safety.

Food Packaging Standards: FDA, EFSA, and HACCP

Food packaging must comply with strict safety regulations. The FDA (U.S.), EFSA (European Food Safety Authority), and HACCP (Hazard Analysis and Critical Control Points) enforce global food packaging security.

FDA and EFSA guidelines require tamper-evident packaging for food and beverages. Sealed containers, security labels, and protective films prevent contamination. These measures help ensure product integrity from production to consumption.

HACCP outlines risk prevention in food packaging. It focuses on identifying hazards and preventing foodborne illnesses. Businesses must use secure packaging solutions to comply with international food safety laws.

Steps to Ensure Compliance with Tamper-Evident Packaging Standards

Step 1: Conduct a Compliance Audit

A thorough audit helps identify gaps in current packaging security. Companies must assess their processes, resources, and documentation against international organization guidelines. Key areas to evaluate include:

- Labeling Act and Consumer Commodities Compliance: Ensure net contents, warnings, and security labels meet regulations.

- Pharmaceutical Packaging & Medical Devices: Verify adherence to FDA, EU, and WHO security rules.

- Carbon Emissions & Sustainability: Review packaging materials to meet eco-friendly requirements.

An effective audit helps companies stay compliant and avoid legal issues.

Step 2: Choose the Right Tamper-Evident Packaging Solutions

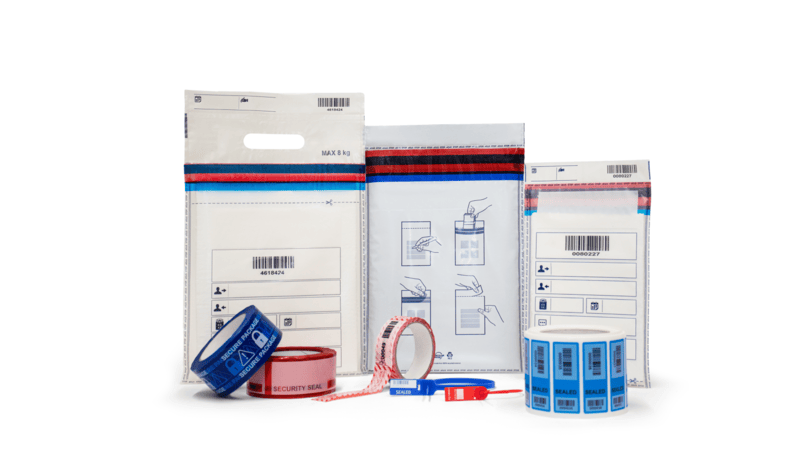

The second step is to select the right tamper-evident packaging solutions. The right solutions depend on factors like product type, risk level, and regulatory mandates. Companies in pharmaceutical packaging, medical devices, food, and other areas must implement effective security measures.

These include security seals, security labels, tapes, bags, and bag tapes. Choosing the correct solution helps meet national institute standards, protect consumers, and reduce carbon emissions by preventing waste from tampered goods.

The following table outlines different tamper-evident solutions and their types:

Solution | Types |

Security Seals |

|

Security Labels |

|

Security Tape |

|

Security Bags |

|

Security Bag Tape |

|

Step 3: Implement Compliance Training & Quality Control

Next, training employees and supply chain partners is crucial for compliance. They must understand reporting requirements, documentation—and security protocols. Regular training ensures that all stakeholders follow industry regulations.

Companies should focus on pharmaceutical packaging, medical devices, and consumer commodities. Different individual states and the European Union have specific regulations, as discussed in detail above. Clear guidelines help businesses meet compliance across all the countries they operate in.

Strong quality control processes prevent tampering risks. Regular inspections and investigation of security breaches are necessary. A compliance team should oversee audits and ensure proper implementation of safety measures.

Step 4: Monitor & Update Compliance Measures

Regulatory Compliance is an ongoing process that requires continuous evaluation. Companies must conduct routine investigations and testing to ensure their tamper-evident packaging and tamper technologies meet the latest international organization and European Union standards.

Researching stakeholder expectations, industry trends, and regulatory updates allows businesses to adapt and improve their packaging security. Understanding developments in other areas ensures long-term regulatory compliance and competitive advantage.

Common Challenges & How to Overcome Them

Ensuring regulatory compliance in tamper-evident packaging comes with challenges. Addressing these issues requires a proactive approach. Here are a few common challenges and their solutions.

Keeping Up with Changing Regulations

Solutions: Regulatory monitoring tools.

New compliance frameworks and global standards emerge regularly. Companies must stay informed to avoid penalties. Using regulatory monitoring tools helps track updates from bodies like the Federal Trade Commission and international agencies. A compliance officer should oversee policy changes and ensure packaging meets new regulatory requirements.

High Costs of Tamper-Evident Packaging

Solutions: Cost-benefit analysis & ROI evaluation.

Security solutions can be expensive, but they reduce risks like counterfeiting and tampering. Businesses should conduct a cost-benefit analysis to compare expenses with long-term savings. An ROI evaluation helps justify investments by highlighting reduced losses and stronger consumer trust.

Supply Chain Enforcement Difficulties

Solutions: Smart tracking & digital verification.

Ensuring tamper-evident packaging remains intact throughout distribution is complex. Smart tracking technologies and digital verification tools enhance visibility. Using security labels, seals, or packaging with visible evidence of tampering helps identify breaches early. Strong compliance frameworks ensure all partners follow the same security protocols.

Overcoming these challenges strengthens regulatory compliance and protects both products and consumers.

FAQs

What industries require tamper-evident packaging compliance?

Industries like pharmaceuticals, food and beverage, cosmetics, and logistics must follow tamper-evident packaging rules.

How can small businesses afford international compliance?

Small businesses can use cost-effective solutions like security labels and tamper-evident tapes. Conducting a cost-benefit analysis and choosing industry-specific compliance frameworks helps manage expenses.

What are the penalties for non-compliance with packaging security regulations?

Fines, recalls, and legal action vary by industry and region.

Conclusion

Tamper-evident packaging is vital for security and compliance. Businesses must follow global regulations to protect their products and consumers. Regular audits, strong security measures, and staff training ensure long-term compliance. Stay ahead by adapting to new standards. Invest in reliable packaging solutions today to secure your business and build trust.

Shosky Security: Your Partner in Meeting International Tamper-Evident Standards

Don’t let compliance challenges put your business at risk! Shosky Security offers quality tamper-evident packaging solutions to keep your supply chain secure. Contact us to get a quote today!