Consumers are increasingly demanding authenticity. They want to know the products they buy are genuine and come from trusted sources. However, with counterfeiting becoming more sophisticated, 30% of consumers have unknowingly bought fake goods.

A custom-made hologram sticker offers a powerful way to build trust and foster brand loyalty. The unique, visually impressive nature of these stickers reassures customers that they’re purchasing an authentic product while simultaneously enhancing your brand’s image as innovative and sophisticated. This article details how to use security hologram stickers to create a stronger connection with your customers and protect your revenue.

What are Holographic Stickers?

At their core, holographic stickers or holographic labels are advanced adhesive labels that incorporate diffractive optical technology to create a striking, multidimensional visual effect. The sticker’s surface features intricate microstructures or laser-etched patterns that refract light, generating a dazzling, 3D-like appearance.

It is vital to distinguish between a standard “decorative” hologram and a true “security” hologram. A decorative hologram, like those found on stickers for children, is a simple, repeating pattern that is easily copied.

A security hologram, however, originates from a unique master plate containing specific optical data. It includes covert features, forensic elements, and complex layering that make it incredibly difficult and expensive for counterfeiters to replicate.

5 Key Types of Hologram Sticker Options for Brand Protection

Choosing the correct type of hologram is crucial because different packaging materials and security risks require different technical solutions.

1. 2D/3D Hologram Sticker Types

2D/3D hologram stickers are the most common entry points for brands. They work by placing multiple two-dimensional layers of artwork at different visual depths. One layer might sit in the background while another appears to float in the foreground. The result is a distinct sense of depth and parallax.

These are excellent for general branding because they are bright, colorful, and easily recognized by consumers on a retail shelf.

Best For: General branding and visual appeal. They offer excellent depth and distinct colors, making them ideal for retail packaging where shelf appeal is a priority.

2. Dot-Matrix Hologram Sticker Solutions

If you need high-energy visual effects, dot-matrix is the industry standard. These holograms are created using computer-controlled laser systems that etch millions of tiny dots or “pixels” into the master plate.

Because this is done digitally, it allows for incredibly high resolution and complex “kinetic” effects. You can simulate animation, zooming, or spinning wheels that react when the customer tilts the package. This is often the preferred choice for electronics and high-tech industries.

Best For: Electronics, high-tech products, and documents requiring high-security details.

3. E-Beam (Electron Beam) Hologram Sticker Technology

For the highest level of security, brands turn to E-Beam technology. Instead of using lasers, this method uses electron beams to create optical grooves with nanometer precision. This allows for features like hidden images and microscopic text that are sharper than what optical lasers can produce.

E-Beam holograms are notoriously difficult to counterfeit because the equipment required to originate them is extremely rare and expensive.

Best For: Supply chain visibility (Track & Trace) and consumer verification. Customers can scan the code to verify authenticity instantly.

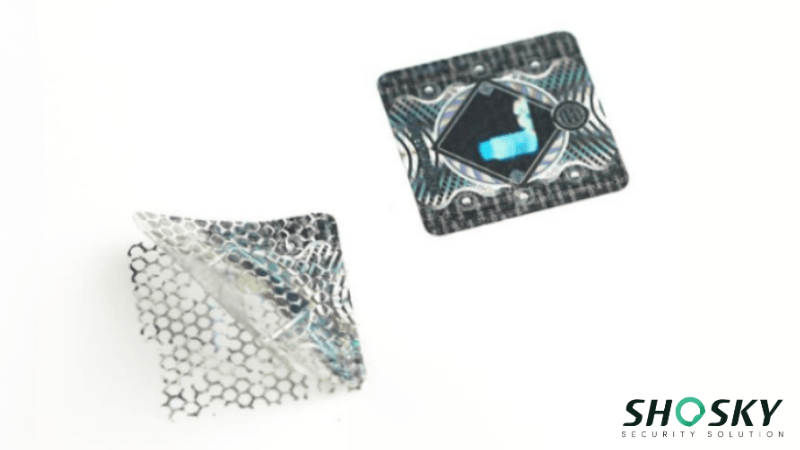

4. Transparent / Overlay Holograms Sticker Laminates

Sometimes you need to secure information without covering it up. Transparent holograms are clear films embedded with ghost-like holographic images. These are typically applied over printed data, such as a photograph on an ID card, a serial number on a pharmaceutical box, or a barcode.

They protect the underlying data from being altered (like scratching off a number) while verifying the document’s authenticity.

Best For: ID cards, passports, badges, and documents where information must remain visible.

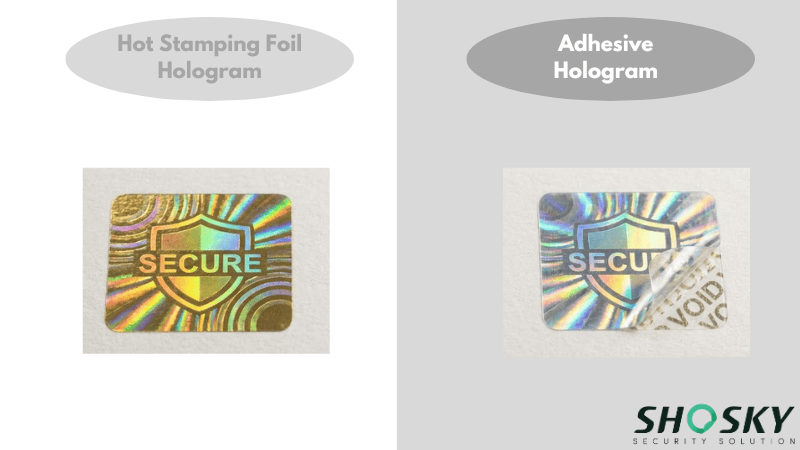

5. Hot Stamping Foil vs. Adhesive Hologram Sticker Labels

While most holograms are applied as stickers, hot stamping integrates the hologram directly into the packaging material. Using intense heat and pressure, the holographic image is transferred from a carrier foil onto the paper or carton board. Once applied, it cannot be removed or peeled off because it has effectively become part of the box surface.

Best For: Premium packaging boxes, wine labels, and cosmetic cartons where a seamless, luxury look is required and label removal must be impossible.

Once you have selected the type of hologram that fits your packaging, you need to decide which security features to embed within the image itself.

Essential Anti-Counterfeit Features of a Hologram Sticker

A truly secure hologram sticker functions like a fortress with multiple layers of defense. Instead of just throwing random effects together, security experts categorize these features into three distinct levels of verification: Overt, Covert, and Forensic.

Level 1: Overt Features (Visible to the Naked Eye)

These features are the front line of defense. They are designed for the end consumer who needs to verify a product in seconds while standing in a store aisle.

- Kinetic Movement: As the label is tilted, elements of the design should appear to move, rotate, or expand. This movement is impossible to replicate with a photocopier.

- True Color: The hologram switches between specific, bright colors at distinct angles rather than a generic rainbow wash.

- 3D Depth: The logo or central icon appears to sit deep behind the label surface.

Level 2: Covert Features (Hidden from Sight)

These features are invisible to the naked eye. They are designed for retailers, customs officers, and supply chain inspectors who have simple tools like a magnifying glass or a UV light.

- Microtext: This involves embedding text that is smaller than 0.1 millimeters into the design. To the naked eye, it looks like a solid line or a decorative border. Under a magnifying glass, the text becomes readable. Counterfeiters using digital scanners will lose this resolution, resulting in a blurry line on fake labels.

- UV Luminescence: Using invisible inks, manufacturers can print a logo or code on the hologram sticker that only glows red, blue, or yellow under an ultraviolet lamp.

- Laser-Viewable Images (CLR): This is a hidden image encoded into the hologram structure that can only be seen when a laser pointer is shone on the label at a specific angle, projecting the image onto a wall.

Level 3: Forensic Features (Lab Verified)

These are the deepest secrets of the hologram, known only to the brand owner and the manufacturer. They require laboratory equipment to identify. This might include molecular taggants added to the adhesive or specific nano-structures in the foil. These features are used in court cases to prove definitively that a product is counterfeit.

The effectiveness of these features relies heavily on how the hologram is manufactured. Understanding the production process can help you justify the investment.

The Manufacturing Process of Hologram Stickers

The creation of a security hologram sticker is a complex industrial process that blends optical physics with precision embossing.

Step 1: Master Origination

This is the most expensive and critical part of the process. A master plate (usually made of nickel) is created in a secure laboratory. This plate contains the microscopic grooves that will diffract light. This step is where the unique design, including all covert and overt features, is physically created.

Step 2: Recombination and Electroforming

A single hologram image on a master plate is not enough for mass production. The image is replicated hundreds of times onto a larger “shim” using a process called recombination. This shim is then placed in an electroforming tank to create durable metal stamping plates.

Step 3: Micro-Embossing

The holographic image is transferred onto a roll of polyester (PET) film. This is done using heat and massive pressure to press the microscopic grooves from the metal shim into the plastic film. This process, called micro-embossing, is what allows the plastic to reflect light in specific patterns.

Step 4: Metallization and Coating

To make the hologram reflective, the embossed film is placed in a vacuum chamber where a thin layer of aluminum is evaporated onto the surface. This turns the transparent grooves into a mirror-like finish. Finally, adhesive and release liners are added to turn the foil into a usable hologram sticker.

Understanding the technical complexity of manufacturing highlights why these labels are so secure. However, modern security goes beyond just the physical label. It now integrates with the digital world.

How to Choose the Right Hologram Sticker?

With so many technical options available, making the right choice can feel overwhelming. The key is to balance your security needs against your budget and operational realities. You do not want to under-protect a high-value asset, but you also do not want to overspend on forensic features for a low-cost consumer item.

To make the best decision, start by assessing your Risk Profile.

- Low Risk: For items like stationery or low-cost apparel where the main goal is shelf appeal, a standard 2D/3D hologram provides enough visual deterrence.

- High Risk: For pharmaceuticals, automotive parts, or electronics where safety is a concern, you must invest in E-Beam technology and covert features like microtext.

Once you have assessed the risk, you need to decide on two critical strategic elements: Digital Integration and Customization Level.

Digital Integration

In 2025, physical security is merging with digital traceability. A standalone hologram proves the label is real, but it does not track where that specific bottle or box has been. By combining holography with variable data, brands can achieve “Phygital” security.

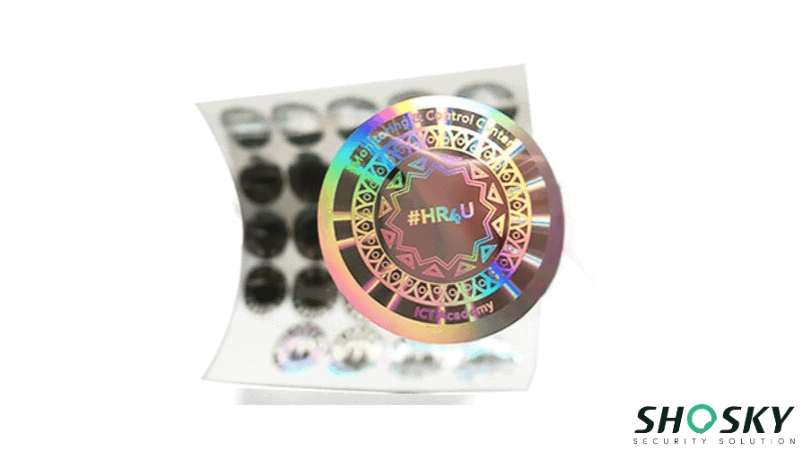

Track and Trace Capabilities

Manufacturers can laser-etch or inkjet-print a unique, sequential serial number or a QR code onto each hologram sticker. This allows brands to track individual units through the supply chain. If a batch of products goes missing or is diverted to an unauthorized market (grey market trading), the brand can identify exactly which distributor was responsible based on the serial numbers found in that region.

Consumer Verification Portals

QR codes integrated into the hologram allow consumers to interact with the brand directly. By scanning the code with a smartphone, the customer is taken to a verification webpage.

- Pass: The page confirms the code is valid and the product is genuine.

- Fail: The page warns the user that the code is invalid or has been scanned too many times, indicating a potential counterfeit.

This interaction also provides brands with valuable data on where their products are being scanned and sold. According to the International Hologram Manufacturers Association (IHMA), the integration of mobile authentication with holograms is one of the fastest-growing trends in anti-counterfeiting.

Customization Level

When purchasing holograms, you will generally face a choice between stock designs and fully custom solutions. This decision usually comes down to budget and timeline. Here is a breakdown of the differences.

| Feature | Stock Hologram Sticker | Semi-Custom Hologram | Fully Custom Master |

|---|---|---|---|

| Security Level | Low to Moderate | Moderate | High / Forensic |

| Origination Fee | None ($0) | Low | High (Setup cost involved) |

| Design | Generic pattern (e.g., "Generic Genuine") | Stock pattern + Overprinted Logo | 100% Unique Brand Design |

| Lead Time | Fast (Off the shelf) | Fast (Days) | Longer (Weeks for master) |

| Exclusivity | Non-exclusive (anyone can buy) | Brand-marked | Exclusive rights to the master |

| Best For | Low-risk items, tight budgets | Medium risk, urgent deadlines | High-risk, high-value brands |

Industry Applications: Who Needs a Hologram Sticker?

While luxury goods are the most obvious candidate, the application of security holograms extends deep into industrial and government sectors.

Automotive Parts

Counterfeit brake pads, airbags, and filters pose a lethal risk to drivers. Major automotive brands use holograms with track-and-trace codes to certify genuine spare parts. This helps mechanics and consumers verify that the part they are installing meets safety standards.

Government and Identification

From tax stamps on tobacco and alcohol to high-security overlays on passports and driving licenses, governments are the largest users of holographic technology. These holograms protect tax revenue and prevent identity theft. Organizations like Interpol regularly emphasize the role of physical security features in distinguishing genuine documents from fakes.

Electronics and Warranty

Tech companies use destructible hologram stickers as warranty seals. Placing a sticker over a screw hole or a casing seam ensures that if the user opens the device to attempt a repair, the seal breaks. This voids the warranty and protects the manufacturer from liability claims on tampered devices.

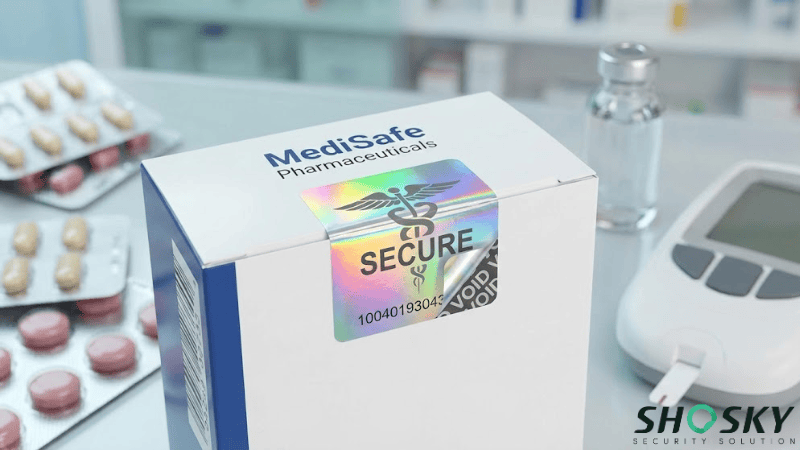

Pharmaceuticals and Healthcare

The World Health Organization estimates that a significant percentage of medicines sold in developing countries are substandard or falsified. A hologram sticker acts as a seal of safety on medicine bottles and boxes. It reassures patients that the drug has not been tampered with and originated from a certified laboratory.

FAQs

Q1: What are hologram stickers made of?

Hologram stickers are typically made from plastic films with a reflective layer that creates a 3D, multi-dimensional visual effect when viewed from different angles.

Q2: How do hologram stickers help prevent counterfeiting?

Hologram stickers feature tamper-evident technology that makes it difficult to replicate or alter. They provide a unique identifier for your brand, making counterfeit goods easier to spot.

Q3: What is the cost of hologram stickers?

The cost of hologram stickers varies depending on factors like customization, quantity, and material. Contact suppliers for specific pricing based on your needs.

Conclusion

Hologram stickers are versatile solutions that combine advanced security features with eye-catching designs to protect products and enhance branding. Businesses across industries, from pharmaceuticals to luxury goods, can use hologram stickers to safeguard their reputation and stand out in competitive markets. Whether used for security, branding, or promotions, hologram stickers provide a unique and effective solution for modern businesses.

Get Premium Custom Hologram Stickers from Shosky!

Shosky Security is your trusted partner for innovative hologram stickers. With over 18 years of expertise, we deliver high-quality, customizable solutions, including advanced features like micro text, QR codes, and dynamic guilloche patterns. Contact us for samples and pricing to elevate your business. Get started today!