In the aftermath of the 1982 Tylenol crisis, tamper-evident packaging became a regulatory standard for pharmaceuticals. And today, its applications span virtually every industry, with a 2024 Harris Poll indicating 73% of consumers now expect visible security features on everything from food products to electronics.

However, despite its widespread adoption, businesses must evaluate their specific needs before implementing tamper-evident solutions. This article outlines five key questions to help you determine whether tamper-evident packaging is essential for your product and how it can align with your business needs.

The Role of Tamper-Evident Packaging in Business Security

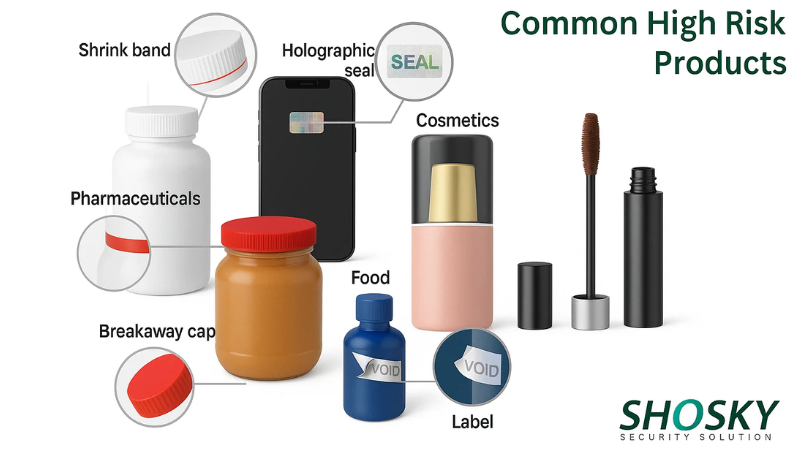

Tamper-evident packaging consists of specialized materials that provide visible evidence when unauthorized access occurs. These security components include labels that display “VOID” patterns, security tapes that tear distinctly, and security seals that break upon opening. Security bags with irreversible closures are also widely used.

Industries dealing with sensitive data, high-value goods, or consumables rely heavily on tamper-evident packaging to ensure product integrity and safety. In pharmaceuticals, tamper-evident seals protect against counterfeit drugs and ensure consumer safety.

Electronics and luxury goods, like watches and jewelry, also use tamper-evident packaging to prevent theft and counterfeiting. In the food industry, packaging provides critical security for consumer safety and meets regulatory compliance.

| Industry | Common Tamper-Evident Methods | Primary Security Concerns |

|---|---|---|

| Pharmaceuticals | Foil seals, shrink bands, breakable caps | Product safety, regulatory compliance |

| Electronics | Security labels, specialty tapes, void seals | Data security, sensitive information protection |

| Food & Beverage | Inner seals, tear strips, breakaway closures | Consumer safety, brand protection |

| Luxury Goods | Holographic labels, security threads, serialized seals | Counterfeiting, brand authenticity |

| Medical Devices | Ultra-destructible labels, RFID tags, tamper bands | Patient safety, compliance requirements |

Tamper-evident packaging serves key functions: deters tampering and indicates unauthorized access. By leaving clear marks of tampering, it helps protect product integrity and customer trust. It also ensures compliance with regulations like FDA food safety standards or GDPR for data protection, providing proof of adherence to legal requirements.

5 Critical Questions to Determine If Your Product Needs Tamper-Evident Packaging

Before investing in tamper-evident packaging, it’s important to evaluate whether your product truly needs it. The following five questions will help you assess your risk, understand your responsibilities, and decide on the right level of packaging security.

1. Is Your Product Prone to Tampering or Counterfeiting?

Certain product categories face significantly higher risks of tampering or counterfeiting due to their value or nature. Pharmaceuticals, electronics, cosmetics, and food products typically require stronger protection measures throughout the supply chain. Understanding your specific risk profile helps determine appropriate security investments.

Industry data reveals concerning trends across sectors. National Institutes of Health (NIH) documented over 5,000 incidents of pharmaceutical tampering annually, while the cosmetics industry faces estimated $5.4 billion yearly losses from counterfeit products. Such statistics highlight the need for protective packaging components.

High-risk product categories requiring tamper-evident features include:

- Pharmaceuticals and medical devices

- Premium electronics and components

- Luxury cosmetics and personal care items

- Food products, especially infant formula and supplements

- High-value branded merchandise

Implementing tamper-evident labels, security tapes, and breakaway closures provides visible evidence of unauthorized access. These security elements create immediate visual indicators when tampering attempts occur, deterring potential tampering and alerting consumers to compromised packaging. According to security experts, even basic tamper-evident features can prevent most opportunistic tampering attempts.

2. Are You Operating in a Highly Regulated Industry?

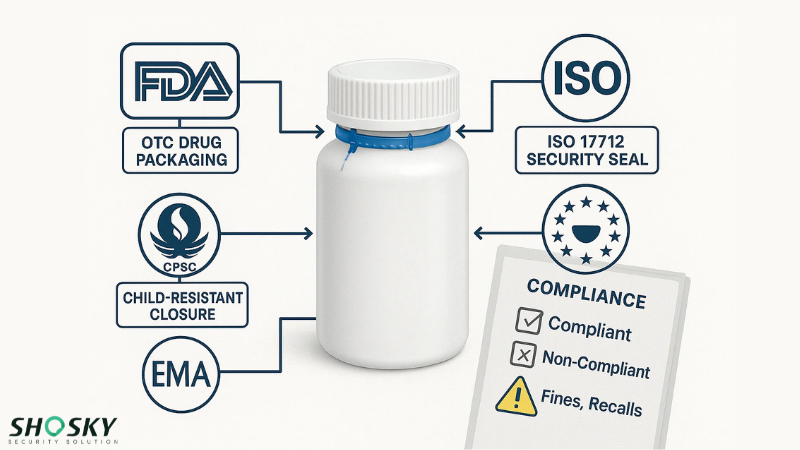

Many industries face strict regulatory requirements that mandate specific tamper-evident packaging components as compliance measures. These regulations exist to protect consumers from potential harm and establish standardized security practices across sectors. Failing to meet these requirements can lead to significant penalties.

The Food and Drug Administration (FDA) requires tamper-evident packaging for over-the-counter pharmaceuticals in such a manner that provides visible evidence when compromised. Similar standards exist across industries, including ISO 17712 for cargo security seals and specialized requirements for medical devices. Companies must understand which standards apply to their specific products.

Key regulatory bodies mandating tamper-evident features include:

- Food and Drug Administration (FDA)

- Consumer Product Safety Commission (CPSC)

- International Organization for Standardization (ISO)

- European Medicines Agency (EMA)

- National regulatory authorities in export markets

Beyond compliance, proper documentation of your tamper-evident packaging systems becomes crucial during regulatory audits. Companies unable to demonstrate adequate protection measures face potential fines, product recalls, or market restrictions. Maintaining detailed records of security implementations helps ensure audit readiness while protecting organizational goals.

3. Do You Ship Products Through Long or Complex Supply Chains?

Products moving through extensive logistics networks face increased exposure to tampering risks at multiple touchpoints. Each handling stage presents another opportunity for unauthorized access, from manufacturing facilities to distribution centers, warehouses, and retail locations. Extended supply chains inherently increase security vulnerabilities.

Supply chain security analyses show products with five or more handling stages experience a 37% higher risk of tampering compared to direct-to-consumer models. International shipping introduces additional complexities, with customs inspections and cross-border transfers creating potential security gaps requiring specialized protection methods.

Critical supply chain vulnerability points include:

- Manufacturing-to-distribution transfers

- Third-party logistics handoffs

- Customs and international transit

- Warehouse storage periods

- Retail receiving and shelving processes

Implementing void labels, security tapes, and serialized seals provides critical protection throughout complex supply chains. These tamper-evident features create readily identifiable indicators when products have been compromised at any stage. Companies utilizing comprehensive tamper-evident systems report stronger relationships with distribution partners and higher customer trust levels.

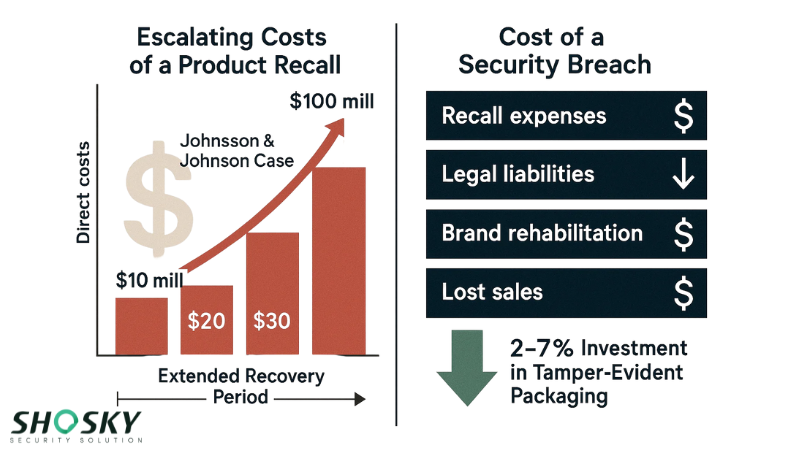

4. What Would Be the Cost of a Security Breach or Recall?

The financial impact of compromised products extends far beyond immediate replacement costs into potential reputational damage. According to a study, a single product recall typically costs between $10 and $ 30 million in direct expenses. However, long-term brand damage often proves even more devastating to business sustainability.

Major recalls demonstrate these consequences clearly. The 1982 Tylenol tampering incident cost Johnson & Johnson over $100 million in immediate expenses, while more recent tampering cases have led to multi-year sales declines for affected brands. Consumer trust, once broken, requires significant resources and time to rebuild.

Potential costs of security breaches include:

- Immediate product recall expenses

- Legal liabilities and settlements

- Brand rehabilitation campaigns

- Lost retailer relationships

- Sustained sales declines

- Market share erosion

Tamper-evident packaging serves as a cost-effective risk mitigation strategy compared to potential damages. Companies investing in appropriate security features typically spend 2-7% more on packaging components but significantly reduce exposure to catastrophic losses. This preventative approach protects both financial assets and hard-earned customer relationships.

5. Do Your Customers or Retailers Expect Visible Security Features?

Consumer expectations around product safety continue evolving, with research showing 76% of shoppers specifically looking for tamper-evident features before purchasing consumable products. This trend extends beyond pharmaceuticals into electronics, cosmetics, and household goods as customers increasingly demand visible security assurance.

Major retailers have responded by implementing stricter vendor requirements around tamper-evident packaging. Leading retail chains now include specific security labeling guidelines in their compliance standards, making these features necessary for market access and maintaining positive vendor relationships.

Rising consumer security expectations by product category include:

- Consumables: 76% expect visible tamper-evident features

- Pharmaceuticals: 89% check for intact seals

- Premium electronics: 67% prefer security-labeled packaging

- Children’s products: 82% prioritize tamper-evident packaging

- Health and beauty items: 71% look for security features

Tamper-evidence components provide visible symbols of brand protection that strengthen consumer trust. Forward-thinking manufacturers recognize these security elements as more than compliance measures—they represent a tangible demonstration of your commitment to product safety and customer protection. This visible evidence helps differentiate products in competitive markets.

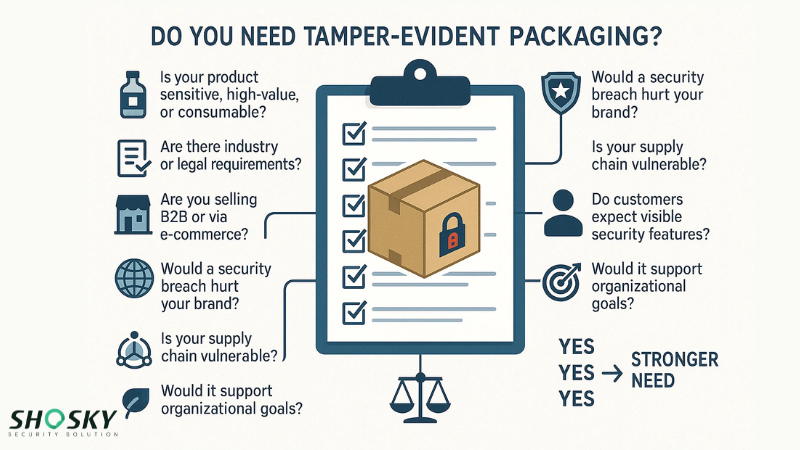

Tamper-Evident Packaging Checklist (Quick Summary)

Besides the 5 critical questions discussed above, assess your product’s security needs by answering these essential questions:

- Is your product sensitive, high-value, or consumable?

- Are there industry or legal requirements?

- Are you selling B2B to retailers or via e-commerce?

- Would a security breach hurt your brand?

- Is your supply chain vulnerable to tampering?

- Do your customers expect visible security features?

- Would tamper-evident packaging support your organizational goals?

- Have you evaluated the benefit-risk balance?

These questions help you decide if tamper-evident packaging is truly necessary. They highlight key risks—like product sensitivity, legal requirements, or a complex supply chain—and show where added security may be needed.

They also help weigh the cost against the risk of damage to your product, customers, or brand. Asking them ensures your packaging decisions match your business goals and customer expectations.

Choosing the Right Tamper-Evident Solution for Your Product

Selecting the right tamper-evident solution starts with understanding what options are available. From tapes and labels to bags and seals, each solution plays a key role in protecting your products. Let’s take a closer look at the different types of tamper-evident packaging and what to consider when choosing the best fit for your needs.

Types of Tamper-Evident Packaging

Tamper-evident packaging comes in various forms that are designed to protect your products from unauthorized access. Security bag tape, ultra-destructible labels, tamper-evident bags, and security seals are just a few examples. Each type serves a different purpose, but all are essential in preventing tampering and safeguarding against data breaches.

These tamper-evident solutions are also critical for ensuring compliance with regulations like the General Data Protection Regulation (GDPR). By clearly indicating if tampering has occurred, these solutions offer a better understanding of your product’s security and help identify potential risks.

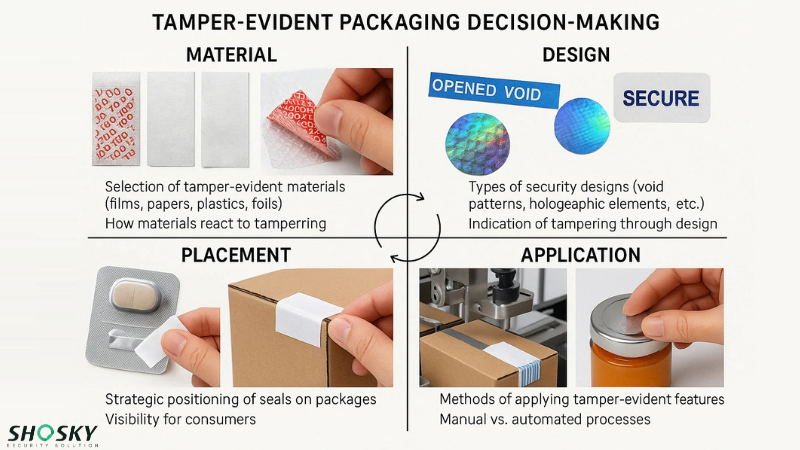

Considerations: Material, Design, Placement, and Application

When selecting the right tamper-evident solution, consider the material used for packaging. The material should be durable enough to withstand external manipulation, protecting your product and sensitive data. It’s important to choose materials that align with your product’s specific needs and security requirements.

Design and placement also play an important role in the effectiveness of tamper-evident packaging. The security features should be strategically placed so they’re easily visible and functional. Commonly used designs offer a balance between visibility and practicality, ensuring that tampering is easily identified without compromising the user experience.

The application process of tamper-evident features should be simple yet effective. By ensuring that these solutions are easy to apply in large quantities, you can streamline production while maintaining high security standards. This balance between ease of use and effectiveness is crucial to preventing data breaches.

Customization for Brand Alignment and Security

Customizing your tamper-evident packaging is an excellent way to reinforce both your brand identity and security. By integrating logos, colors, and branding elements into your security features, you can create a packaging solution that speaks to your brand’s commitment to quality and protection.

Customization also enhances the consumer’s experience, allowing them to easily identify your product while knowing it is securely packaged. With a strong focus on tamper technologies, customers can feel more confident in your products, which can improve trust and brand loyalty.

This customization, paired with the importance of security, makes your packaging stand out. It not only provides tamper-evidence but also aligns with data protection regulations, ensuring that your products are safe and compliant with industry standards like GDPR (General Data Protection Regulation).

Work with a Supplier for B2B-Tailored Solutions

Partnering with a trusted supplier offers a better understanding of the available tamper-evidence solutions. Suppliers can help you identify the best packaging options that meet both security needs and branding objectives. Their expertise ensures that your packaging is both effective and compliant with relevant regulations.

Working with a supplier also ensures that you have access to tailored solutions for your business. Suppliers commonly offer customized solutions that address the unique challenges of your industry, preventing data breaches while maintaining product integrity.

Having a reliable supplier allows for a consistent flow of high-quality tamper-evident packaging, meeting your security and business needs. This partnership can help you streamline operations while ensuring your packaging remains secure and effective!

FAQs

What is tamper-evident packaging?

Tamper-evident packaging is designed to show visible signs of tampering, ensuring product security.

Which industries require tamper-evident packaging?

Industries like pharmaceuticals, food and beverages, electronics, and logistics commonly require tamper-evident packaging.

Can tamper-evident features be branded?

Yes, tamper-evident features can be customized to match your brand’s design. This allows you to incorporate logos and colors while maintaining security.

Conclusion

Tamper-evident packaging isn’t just about following rules—it’s about protecting your product, your brand, and your customers. And asking the right questions helps you assess risk and choose the best solution. When done right, tamper-evident packaging builds trust, prevents loss, and shows your commitment to safety, exactly what today’s consumers and retailers expect.

Secure Your Supply Chain with Tamper-Evident Packaging from Shosky Security

If you’re looking for high-quality, reliable tamper-evident packaging for your products, Shosky Security is the partner you need. Talk to the experts at Shosky Security and safeguard your packaging with custom tamper-evident solutions! Contact us to get started.