A recent study by the National Institute of Standards and Technology (NIST) found that traceability in the supply chain can reduce fraud and product tampering by up to 30%. And one of the most effective ways to enhance traceability is through custom security seal numbering.

Assigning different serials to each security seal gives companies tighter oversight of their goods and reduces the risk of loss or interference. In this article, we’ll explore how serial numbering improves traceability and why it matters for today’s supply chains.

What Is Serial Numbering on Security Seals?

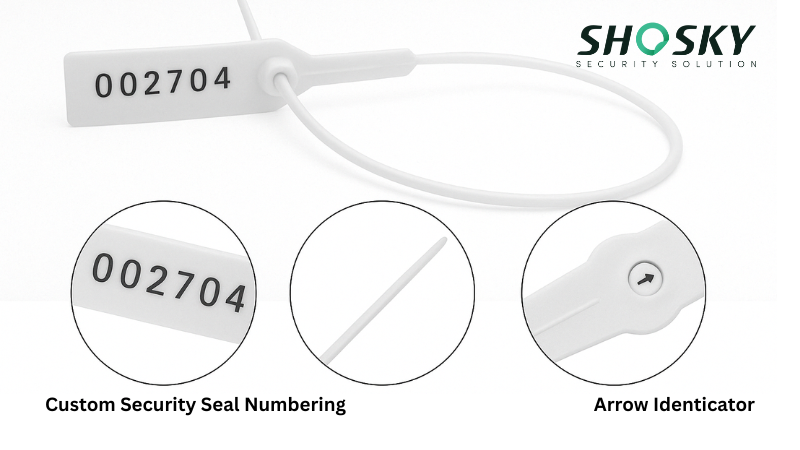

Serial numbering on a security seal is a security feature that assigns a unique number to the seal. This number is printed, engraved, or laser-marked on the security seal, making each seal distinct.

When each seal carries a unique serial number, it becomes easier to log, monitor, and verify individual shipments at every stage — from packaging to delivery. If tampering or theft occurs, the serial numbers help pinpoint where it happened, enabling faster investigations and stronger preventive measures.

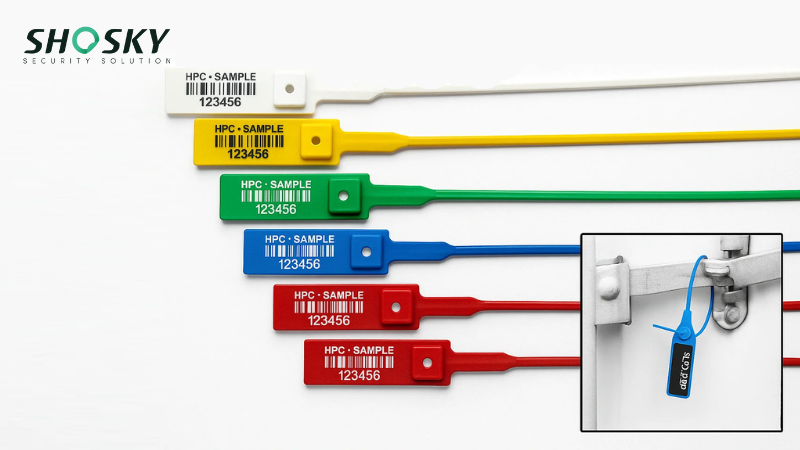

Unlike generic numbering, companies can include barcodes, QR codes, or alphanumeric sequences as numbering for better identification.

Standard Numbering vs. Custom Numbering

Standard numbering on security seals usually follows a basic sequence like 001 to 1000. While easy to apply, it’s predictable and offers low protection in high-security settings. Because these numbers follow a pattern, they can be copied or altered. This makes counterfeiting and unauthorized replacements much easier.

Custom serial numbering uses unique identifiers that are harder to replicate. These may include company-specific codes, barcodes, or encrypted data. For example, a seal marked “XYZ-2025-A3B7” could show the company, year, and unique code. This makes the seal more secure and trackable.

Custom numbers also connect with tracking systems, helping companies spot tampering, trace movements, and stay compliant with industry rules.

How Does Custom Serial Numbering on Security Seals Enhance Security?

For Manufacturers: Prevents Unauthorized Access and Counterfeiting

Custom serial numbers help manufacturers prevent counterfeiting and protect their goods. When each seal has a unique code, it’s hard to copy. If someone tries to swap a seal, the mismatch will show instantly. Furthermore, if there is an unauthorized attempt to access it, the seal will be broken or damaged, alerting to tampering.

For manufacturers, this is especially important. Custom numbering:

- Lowers the risk of fake products entering the chain

- Deters unauthorized access at every stage

- Strengthens product traceability from raw materials to delivery

These unique codes improve product traceability by linking tamper-technology seals to a specific item or batch. Manufacturers can track raw materials, monitor movement, and improve chain traceability across the process. It’s not just security—it’s a key part of modern, responsible manufacturing.

For Logistics: Enables Real-Time Shipment Tracking and Authentication

Serial numbers allow companies to track shipments in real-time. Digital logging systems record the movement of each seal. By integrating barcodes or QR codes, instant authentication becomes possible. This ensures that only authorized personnel can verify and break the seals.

For logistics, the custom serial numbering on security seals:

- Offers immediate visibility into the location and status of shipments.

- Allows for rapid authentication using scanning technology.

- Limits verification access to designated personnel.

Real-time tracking allows businesses to manage their supply chain operations better. The systems provide valuable data that allows them to identify any potential issues quickly. This enhances traceability and improves the overall efficiency of the distribution process.

For Quality Assurance: Improves Traceability and Accountability

Serial numbers make it possible to trace defective or tampered products back to their original source. This reduces the risk of contamination, particularly in sensitive industries like food and pharmaceuticals. This is vital for maintaining high-quality standards.

For quality assurance, the custom serial numbering on security seals:

- Enhances internal audits and promotes accountability among handlers.

- Reduces the potential for contamination in sensitive industries.

- Facilitates tracing of defective or tampered goods to their origin.

These numbers enhance traceability throughout the manufacturing process. They help to identify the source of any defective products, allowing for rapid product recall. This improves overall production and ensures that consumers receive safe and reliable goods.

For Retail & E-Commerce: Prevents Fraud

Stores and online shops use security seals to protect valuable e-commerce shipments. These include things like electronics, luxury items, and medicines. Serial numbers add extra security. They stop people from opening packages without permission. They also prevent false claims.

For retail and online stores, the custom serial numbers on security seals do several things:

- They keep goods safe from the warehouse to the customer.

- They help check returns by matching numbers to the original shipment.

- They guard against theft and package tampering during delivery.

When businesses use security seals with serial numbers, they build customer trust. Customers feel more confident knowing their orders are secure. Seals show that packages have not been opened or altered. Reliable deliveries create a better shopping experience.

For Compliance Teams: Enhances Regulatory Adherence

Serial numbers play a key role in meeting industry regulations. Many sectors, such as pharmaceuticals, food safety, and customs, require strict traceability measures. Unique numbering ensures that businesses follow ISO standards and other security protocols.

For compliance teams, the custom serial numbering on security seals:

- Supports adherence to ISO standards and government security protocols.

- Helps companies avoid penalties for non-compliance.

- Facilitates the creation of accurate documentation for audits and legal needs.

Keeping detailed records of serial numbers simplifies regulatory checks. Auditors can quickly verify that the right security measures are in place. This reduces compliance risks and ensures smooth operations across different industries. This is essential for businesses that want to operate responsibly and legally.

Types of Security Seals with Custom Numbering

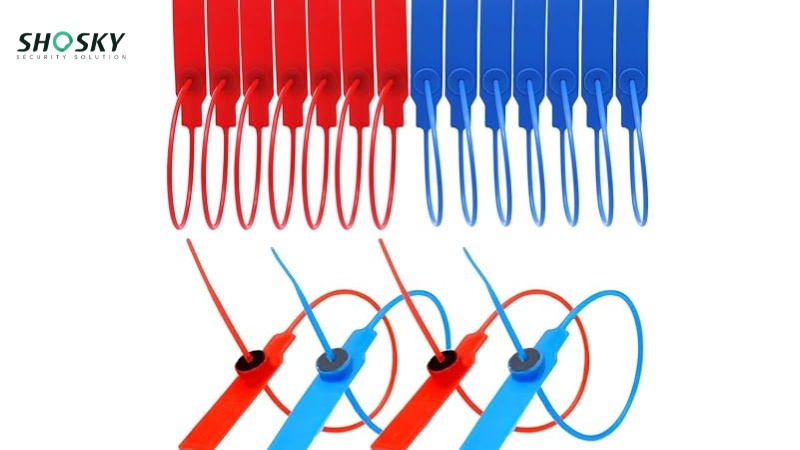

Plastic Security Seals

Plastic security seals are a lightweight, cost-effective, and easy-to-use security seal type. They are commonly used in healthcare, logistics, and retail to prevent unauthorized access. These seals come with unique serial numbers, allowing for easy tracking and verification.

They break when tampered with, providing clear evidence of interference. Examples of plastic seals are numbered cable ties and pull-tight seals. Plastic seals are good for short-term security needs. They’re versatile, so they can be used to secure various assets.

Metal Security Seals

Metal security seals offer more durability and protection against tampering. They’re used in transportation, shipping, and high-security applications. Each seal has a custom serial number so you can track and detect unauthorized access.

These seals require tools for removal, preventing accidental breakage. Examples of metal security seals include bolt seals, cable seals, and indicative seals. The tamper technologies used in them ensure strong protection against theft.

Electronic Seals

Electronic security seals provide advanced tracking and authentication. They integrate digital technology, such as barcodes, QR codes, and RFID chips, for real-time monitoring. These seals improve traceability and security in industries handling sensitive or high-value goods.

Examples of electronic seals include barcode seals, QR code seals, RFID seals, and GPS-enabled seals. These seals help businesses enhance security while ensuring compliance with strict industry regulations. They are particularly useful in the pharmaceutical, food safety, and logistics industries.

Implementation and Management of Custom Security Seal Numbering

Security seal numbering can work with existing systems. Many businesses integrate serial numbering with barcode or RFID technology. This speeds up tracking and reduces human error. Scanners can quickly verify seals, ensuring smooth operations.

To maximize effectiveness, companies should:

- Use tamper-proof printing methods: Engraving, embossing, or laser marking prevents number alterations.

- Set up a centralized database: All numbers should be logged for easy tracking and verification.

- Train employees on proper handling: Staff must know how to record, apply, and inspect numbered seals.

- Conduct regular security checks: Routine audits help identify and address potential issues.

- Integrate with supply and chain systems: Linking seal data with inventory and logistics software improves monitoring.

Effective implementation also requires periodic evaluation of numbering strategies. Businesses should review their security seal data to detect patterns, identify vulnerabilities, and refine processes.

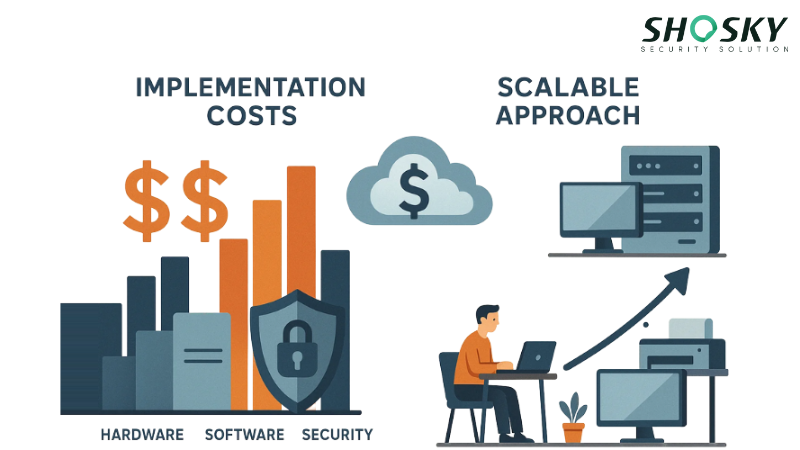

Challenges in Implementing Custom Serial Numbering

Businesses face several challenges when integrating custom serial numbering into their operations. These challenges can affect efficiency, security, and overall workflow.

High Implementation Costs

Developing a custom serial numbering system requires investment in software, hardware, and security measures. Small businesses may struggle with these costs.

Solution: Start with a scalable system that fits current needs and allows future expansion. Cloud-based solutions can reduce upfront expenses.

Compatibility with Existing Systems

Many companies use legacy systems that may not support new numbering formats. Integration issues can lead to data mismatches and workflow disruptions.

Solution: Conduct a system audit before implementation. Use middleware or APIs to bridge gaps between old and new systems.

Employee Training and Adoption

Employees may resist change or struggle to understand the new system. Errors in data entry can lead to tracking issues.

Solution: Provide hands-on training and user-friendly interfaces. Automate serial number generation to minimize human errors.

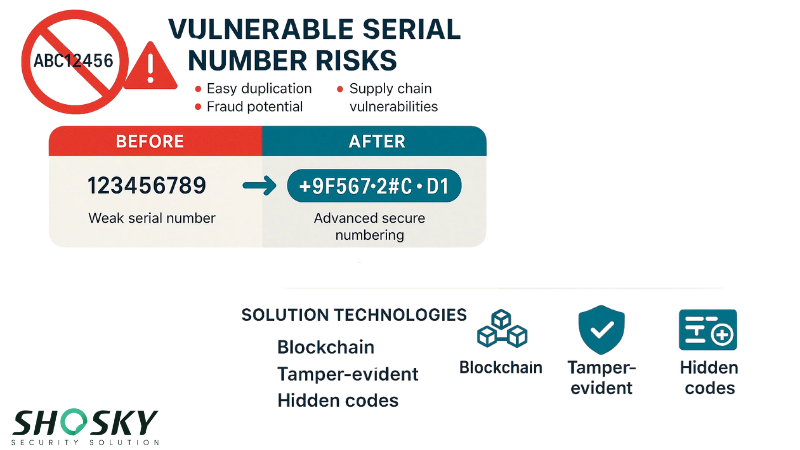

Security Risks and Counterfeiting

Poorly designed serial numbers can be duplicated or manipulated, leading to fraud.

Solution: Implement advanced security features like tamper-evident markings, hidden codes, or blockchain-based tracking.

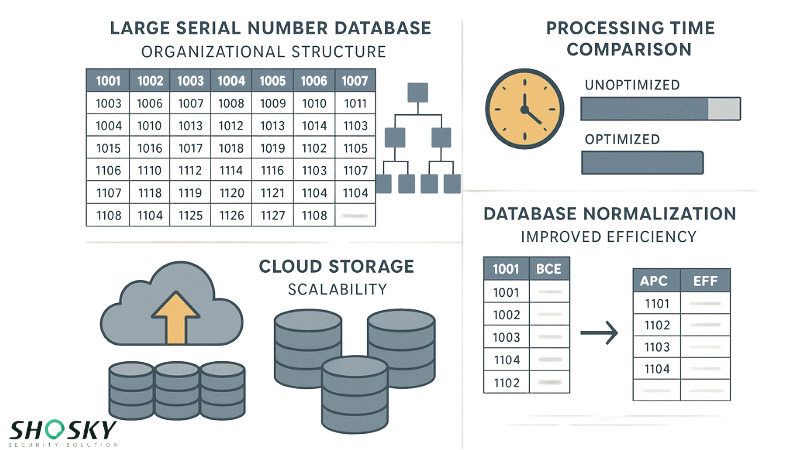

Data Management and Scalability

Handling large volumes of serial numbers requires a well-structured database. Poor data management can cause slow processing times and errors.

Solution: Use database normalization techniques and cloud storage for efficient scaling.

By addressing these challenges early, businesses can implement a secure, efficient, and scalable serial numbering system that improves traceability and operational efficiency.

Best Practices for Security Seal Numbering

Use unique and authentic numbers for each product or batch. No two numbers should be alike. Each number should be distinct and impossible to duplicate. This prevents counterfeiting and makes it easier to track products throughout the supply chain. Businesses should store these numbers in a secure database.

A secure database is essential for effective serial number management. So, businesses should regularly update and audit their databases to ensure accuracy. Automated tracking systems can streamline verification and reduce human errors. Clear guidelines on how to handle and document security seal numbers should be in place.

Custom colors and batch numbers can further enhance security and authenticity. These features make it easier to identify seals. They also make it harder to create fakes. This strengthens the overall security of the shipping process. It also helps track goods more efficiently. This reduces the risk of product defects.

FAQs

Can I customize the numbering format on security seals?

Yes, you can. Businesses can choose custom formats, including sequential, alphanumeric, or barcode-based numbers.

What industries use custom serial numbering on security seals?

Many industries use them. This includes pharma and food. Logistics and retail use them, too.

Are there digital solutions for tracking serial-numbered security seals?

Yes, digital solutions exist. Barcodes and QR codes help track seals.

Conclusion

Security seal numbering is a critical element in maintaining product integrity. Unique numbers improve security. They act as tamper-evident solutions. They also build customer trust, leading to a stronger brand reputation. Overall, investing in custom-numbered security seals creates a secure and efficient supply chain that ensures smooth operations.

Shosky Security’s Security Seal Numbering – Your Best Defense Against Fraud!

Shosky Security provides high-quality, custom-numbered security seals for maximum protection and traceability. With advanced security features and reliable performance, our tamper-proof seals safeguard your supply chain. So, ready to protect your products? Contact us today!