When a product leaves the factory, it needs more than just a user manual and a warranty card. It needs protection against tampering, unauthorized repairs, and misuse. And using warranty void labels ensures that the integrity of the product remains intact throughout its lifecycle.

Besides, these tamper-evident solutions do more than secure key parts; they help build trust between the brand and the buyer. As product security becomes a bigger concern across industries, using warranty void labels is essential. Here’s how they work and why every company should consider them.

What is a Warranty Void Label?

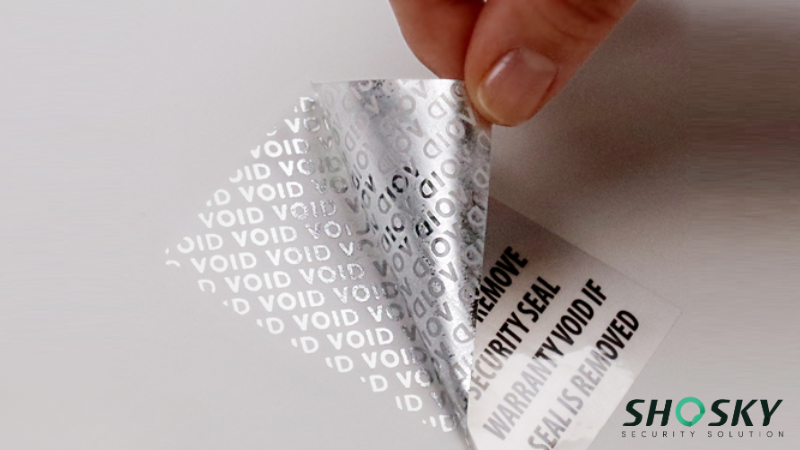

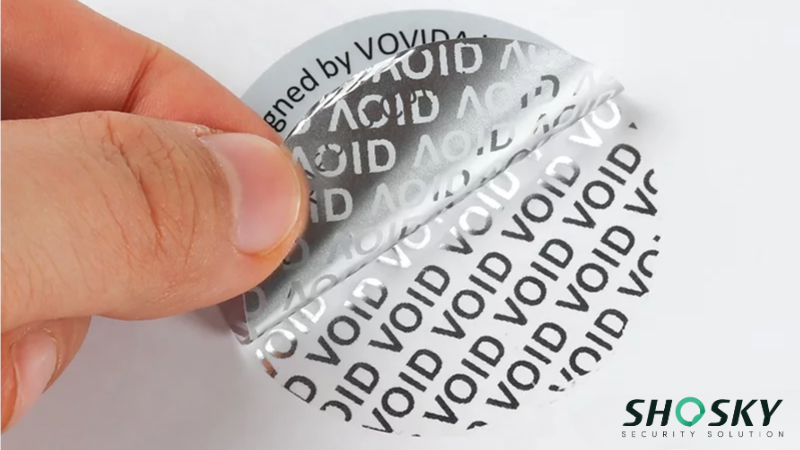

Warranty void labels are advanced security labels that leave a visible “VOID” mark if someone tries to remove or tamper with them. They serve as a critical security mechanism for protecting high-value technological assets across multiple industries.

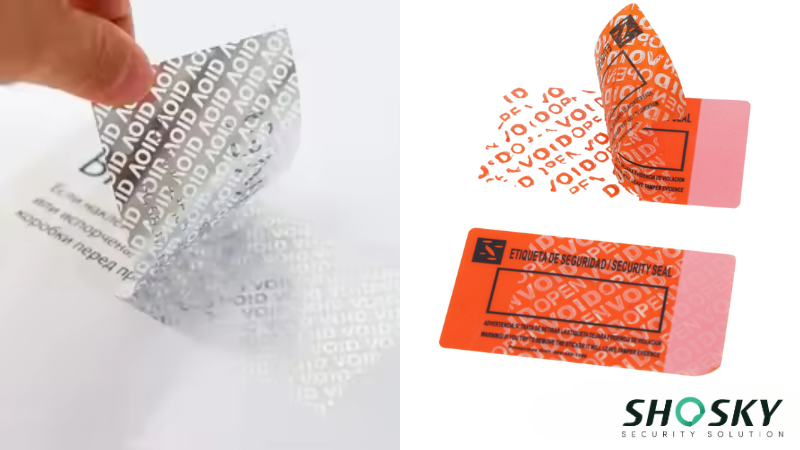

They exist in various material types, shapes, and types of adhesion to suit varying surface types and security requirements. The following are various types used for various product purposes:

- Destructible Paper Labels: Break apart into pieces when removed, making them impossible to reapply.

- Void Pattern Labels: Leave a clear “VOID” mark on the product or surface after removal.

- Holographic Security Labels: Use visual authentication with shifting colors and patterns for higher security.

- Custom-Printed Warranty Labels: Add a company logo, barcode, or serial number for easier tracking and branding.

Warranty void labels are applied to about 78% of consumer electronics and 64% of mechanical equipment to safeguard various products, as per industry reports. Organizations strategically deploy these labels on electronics, industrial machinery, software packages, and precision equipment to offset risks of unauthorized interference and avoid fraudulent warranty claims.

How Do Warranty Void Labels Work?

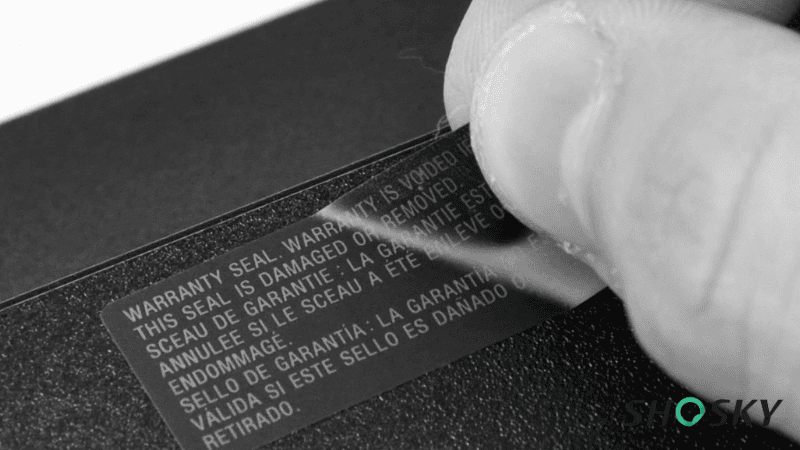

Warranty void labels work on the principle of tamper technologies. They feature special adhesives and materials that respond visibly to any attempt at removal.

The majority of modern labels use pressure-sensitive adhesives that become stronger with time through a process known as “wet-out”, in which the adhesive seeps into microscopic surface irregularities.

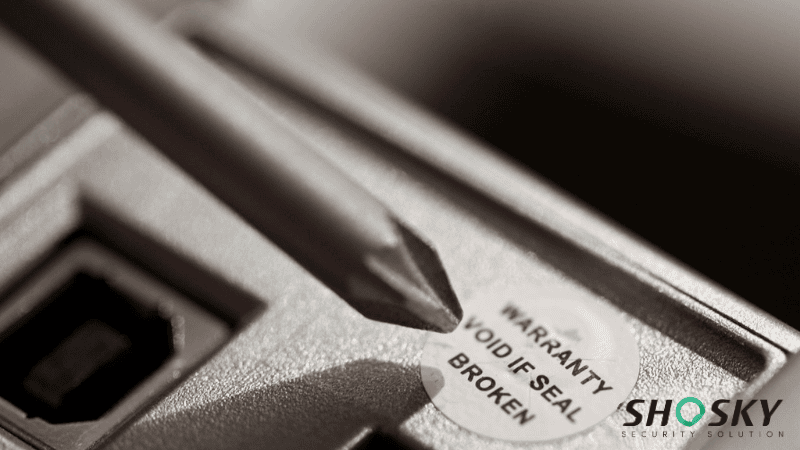

Once applied to seams, screws, or access points, the label creates a seal that cannot be broken without visible damage.

This renders it nearly impossible to remove the label cleanly without destroying the seal. And destroying this seal indicates that the product was opened or tampered with, allowing businesses to enforce warranty conditions.

These labels are commonly applied to electronics, automotive parts, and industrial equipment. Removing or damaging a warranty label can have serious legal implications.

Many companies clearly state in their warranty policy that if the sticker is broken, altered, or missing, the warranty is void. This helps businesses protect against false repair claims and ensures that customers respect the warranty coverage rules.

Why Are Warranty Void Labels Important?

Warranty void labels do more than just mark a product. They help protect your brand, save repair costs, and build stronger trust with customers. Let’s take a closer look at why these labels matter so much for businesses across different industries.

Preventing Unauthorized Repairs or Tampering

One of the main issues that companies and businesses face is the risk of unauthorized repairs or tampering with their products. When customers or third parties attempt to alter a product without proper authorization, it can lead to performance issues, damage, or even void the warranty.

Warranty void labels help mitigate this problem by making any attempts to tamper with the product immediately noticeable by leaving VOID marks.

This discourages end users or third-party individuals from trying to adjust or repair products in a way that can damage sensitive or delicate parts.

Using void labels also helps companies cut down on repair costs caused by unapproved fixes. By showing clear evidence of tampering, businesses can fairly deny warranty claims tied to altered products.

Building Customer Trust with Clear Warranty Enforcement

Clear warranty enforcement builds stronger customer trust. When customers know that a company has measures like warranty void labels in place, it shows that the company values product quality and transparency. Customers can feel more confident that the items they purchase are authentic and protected.

Based on the Marketing Charts report, 7 out of 10 consumers report that they are more likely to trust a brand that secures their products with adequate security measures. And warranty void labels are part of that protection. They help companies show their commitment to customers.

Good warranty practices, combined with visible tamper-proof labels, not only improve a company’s image but also make buyers more likely to return for future purchases. Such enhanced confidence can bring in more customer retention and repeat business, generating long-term business success.

Reducing Product Returns and Fraudulent Claims

Warranty void labels help lower the number of product returns and false warranty claims. If a label shows tampering, companies have solid proof to refuse coverage under the warranty policy. This saves time and resources and protects companies from losses caused by fraud.

A report from the Association of Certified Fraud Examiners (ACFE) found that businesses lose up to 5% of revenue each year due to fraud, including warranty fraud. Adding clear tamper-evident seals like void labels is a simple but powerful way to fight back.

With fewer fraudulent claims to process, businesses can focus more on real warranty cases, improve customer service, and protect their products’ reputation. This also ensures that resources are used more efficiently, allowing companies to allocate funds to areas that genuinely need attention, such as quality control.

Warranty Void Labels vs. Other Tamper-Evident Solutions

When it comes to product protection, warranty void labels are just one of many tamper-evident options. Each method has its strengths depending on the type of item, surface, and security risk involved.

Let’s break down how warranty void labels compare to other popular solutions like security seals, QR-code verification, and RFID tracking, and when it makes sense to combine them.

Warranty Void Labels vs. Security Seals: Which One Offers Better Protection?

Warranty void labels are made to break apart, peel, or reveal a “VOID” mark when tampered with. They stick directly to a product’s vulnerable parts, making unauthorized repairs much harder to hide. This protects the company’s warranty policy and provides visible proof of tampering.

Adhesive security seals, in contrast, are mainly used on boxes and packaging to spot tampering during shipping or storage. They’re easy to apply and work well for bulk handling. However, for electronics, medical gear, or machinery where internal tampering is a concern, warranty void labels offer better precision.

Comparison with QR-Code Verification and RFID Tracking

QR codes and RFID tracking are digital security tools that serve different purposes. QR codes can help customers check warranty status or product authenticity, while RFID chips allow real-time inventory tracking through radio waves.

However, these systems can sometimes be bypassed without obvious signs of tampering. They rely on backend databases and scanning equipment, not on physical tamper-proof evidence.

On the other hand, a damaged warranty void label immediately signals an issue without needing any scanning tool. For businesses looking for simple, visible tamper signs at the product level, warranty void labels are often a better first line of defense.

Situations Where Multiple Anti-Tampering Solutions May Be Needed

In industries like medical devices, aerospace, and consumer electronics, relying on one tamper-evident method may not be enough. High-risk products often use both warranty void labels and digital tracking to secure both the product surface and its data.

For example, an electronics company may apply a destructible vinyl label over a screw and pair it with QR-code verification for online warranty registration. If either layer is compromised, they have proof for a denied repair or return.

The best protection plan usually depends on the product category, shipping conditions, customer expectations, and how valuable or sensitive the product is.

Quick Comparison Table: Warranty Void Labels vs Other Solutions

As companies work to strengthen product security, it’s important to understand how each tamper-evident option compares side-by-side. Here’s a simple table showing the key differences between warranty void labels, security seals, QR-code verification, and RFID tracking.

| Feature | Warranty Void Labels | Security Seals | QR Code Verification | RFID Tracking |

|---|---|---|---|---|

| Visible tamper evidence | ✅ | ✅ | ❌ | ❌ |

| Protects individual parts | ✅ | ❌ | ❌ | ❌ |

| Digital tracking ability | ❌ | ❌ | ✅ | ✅ |

| Cost-effective | ✅ | ✅ | ⚠️Moderate | ⚠️High |

| Surface-level protection | ✅ | ⚠️Partial (outer package) | ❌ | ❌ |

| Needs special equipment to read | ❌ | ❌ | ✅ | ✅ |

While warranty void labels offer a clear and low-cost way to flag tampering, adding QR or RFID systems can enhance tracking and data collection. Choosing the right mix of solutions helps ensure that both the physical product and the warranty process stay fully protected.

Real-World Applications of Warranty Void Labels

Warranty void labels aren’t just theoretical security tools but actively transforming product protection strategies across multiple sectors. Let’s explore how different industries use these specialized labels to maintain product integrity and manage warranty claims.

1. Consumer Electronics: Protecting Complex Devices

In the consumer electronics world, warranty void labels are crucial for safeguarding intricate internal components. Smartphone manufacturers like Apple and Samsung use multi-layered holographic labels that break apart when smartphone cases are opened, immediately revealing unauthorized access.

Key applications include:

- Protecting circuit boards

- Marking battery compartments

- Securing processor and memory components

- Tracking device history through embedded serial numbers

2. Medical Equipment: Critical Safety Compliance

Medical device manufacturers rely on warranty void labels to ensure patient safety and regulatory compliance. These labels help prevent unauthorized modifications that could compromise equipment functionality.

Critical use cases include:

- Marking diagnostic equipment calibration points

- Protecting surgical instrument integrity

- Tracking maintenance history for complex medical machines

- Ensuring sterile packaging remains uncompromised

3. Automotive Industry: Preventing Unauthorized Modifications

Heavy machinery and industrial equipment benefit significantly from the use of robust warranty void labels, which serve a vital role in maintaining operational efficiency and ensuring equipment longevity.

Manufacturers rely on these labels to:

- Track Electronic Control Unit (ECU) tampering

- Monitor warranty-related repairs

- Prevent unauthorized performance modifications

- Validate original manufacturer specifications

Industrial Manufacturing: Equipment Reliability Tracking

Heavy machinery and industrial equipment rely on robust systems to maintain their performance and minimize the risk of failure. Warranty void labels play a crucial role in this by helping manufacturers keep track of the equipment’s condition over time.

Manufacturers use them to:

- Monitor critical component wear

- Track maintenance intervals

- Prevent unauthorized repairs

- Validate original equipment specifications

Tips to Apply and Use Warranty Void Labels Effectively

Using warranty void labels correctly is important to protect your stock, reduce warranty disputes, and keep customer trust strong. Whether you’re preparing products for office use, USA dispatch, or direct sales, a few extra minutes spent applying them properly can make a big difference.

What to Do

Always clean the surface carefully before loading the label. Dust, oil, or debris can weaken the adhesive. A clean surface helps the label bond strongly, saving you from problems during shipping or warranty checks in your office or dispatch center.

Choose the right material and size for the product. Smooth surfaces like metal or plastic fit standard void labels, while rough surfaces work better with destructible vinyl. Many suppliers offer free sample offers, so you can test what fits best before placing a full stock order through your account.

What Not to Do

Do not alter the product after applying the label. Any change that damages the label, like repairs or upgrades, can trigger the VOID mark and cause quick denial of warranty claims during returns or office inspections.

Avoid using basic, non-tamper-evident labels, especially for high-value items. Without strong features, it’s easier for tampering to go unnoticed, leading to more returns, lost trust, and more customer service issues that take time to navigate.

FAQs

Can you remove a warranty void label without damage?

No, warranty void labels are designed to leave permanent marks or damage when removed, indicating tampering.

Are warranty void labels legally binding?

Yes, they are legally binding, as they help protect manufacturers’ warranties by showing evidence of tampering.

How do businesses order custom warranty void labels?

Businesses can order custom warranty void labels by contacting suppliers, providing design details, and selecting materials or security features.

Conclusion

Strong warranty practices start with strong protection, and warranty void labels deliver exactly that. These tamper-evident solutions help businesses stop tampering, lower return fraud, and reassure customers that products meet original standards. No matter what industry you work in, adding high-quality warranty labels can make a real difference!

Boost Brand Trust with Shosky Security Warranty Void Label Options

Don’t leave your products unprotected. Partner with Shosky Security for high-quality warranty void label options that deliver real security and brand protection. Contact us to explore our free sample offer and see how Shosky Security can help you build stronger product trust.