Security breaches through package tampering continue to plague businesses worldwide. The Retail Customer Experience study found that 73% of customers permanently avoid brands after receiving tampered products. However, companies can reduce this risk by incorporating UV ink technology into their packaging.

This technology not only makes tampering detectable but also provides customers with an added sense of security, reinforcing brand trust. In this article, we will explore how UV ink enhances tamper-evident labels and tapes, the benefits it offers across various industries, and why it is becoming a crucial tool in modern packaging solutions.

What Is UV Ink and How Does It Work in Security Printing?

UV ink, or ultraviolet-reactive ink, is a special type of ink that becomes visible only when exposed to UV or black light. Under normal lighting, this security ink often remains completely invisible, making it ideal for security uses where hidden verification is needed. It doesn’t interfere with design, yet delivers strong protection.

There are different types of UV ink used in security printing.

- Invisible UV ink stays hidden until scanned with ultraviolet light.

- Reactive UV ink may change color or glow when exposed to UV rays.

- Fluorescent inks emit a bright glow and are often used to highlight logos or serial numbers for quick identification.

Security ink is commonly applied to tamper-evident labels and security tapes. It can be printed as hidden codes, logos, serial numbers, or watermarks. When tampering occurs, these markings may break, fade, or shift, making the tampering clear under UV light. This adds a strong layer of verification while keeping the product packaging clean and uncluttered.

Tamper-Evident Tapes and Labels with UV Ink: How They Work

Tamper-Evident Tapes

Tamper-evident tapes, also known as security tapes, use UV ink to add an extra layer of security. This ink stays invisible to the naked eye but glows under UV light. Once the tape is peeled or lifted, a tamper-reveal pattern appears. If someone tries to reseal it, the pattern stays broken.

Some tapes combine printed messages with hidden UV features. These include serial numbers, barcodes, or security ink codes that can only be detected with UV equipment. This makes it hard to tamper without being noticed.

These tapes are used in electronics packaging, pharmaceuticals, and shipping boxes. They help protect sensitive documents, devices, and high-value goods. They’re also ideal for warranty protection and tracking returns.

Tamper-Evident Labels

Tamper-evident labels, also known as security labels, go a step further. They combine visible signs of tampering with hidden UV verification. If a label is peeled or moved, it leaves behind a VOID message or breaks apart.

At the same time, UV-reactive inks on the surface or underside reveal hidden messages, logos, or serial codes under ultraviolet light. This dual-layer protection improves both visual and covert security measures. It supports traceability, ensures authenticity, and helps with quick verification.

These labels are used on product seals, warranty void labels, and for brand authentication. They help stop counterfeiting and signal tampering early, without needing complex tools.

Why UV Ink Matters: Key Benefits and Industries That Rely on It?

Tamper-evident UV ink adds an extra layer of security that’s hard to bypass. These invisible inks reveal hidden messages, logos, or codes only under special UV light. This makes tampering easy to detect, even if the surface looks untouched to the naked eye.

It’s a strong tamper-proof tool for anti-counterfeiting, offering fast visual authentication during inspections. UV ink works with serialization and custom printing, making each item easy to track. Unlike visible tags, it blends into the packaging and doesn’t affect branding. It’s also compatible with most security labels, tapes, and printed surfaces.

Because UV security ink is difficult to replicate, it helps protect products at every point in the supply chain. Businesses can print UV features directly on packaging materials, security seals, or tamper-evident labels. These features boost consumer trust and help meet security and compliance needs.

Several industries already depend on these security measures:

- Electronics: Used to expose warranty tampering or fake repairs. UV codes and security tapes show any interference.

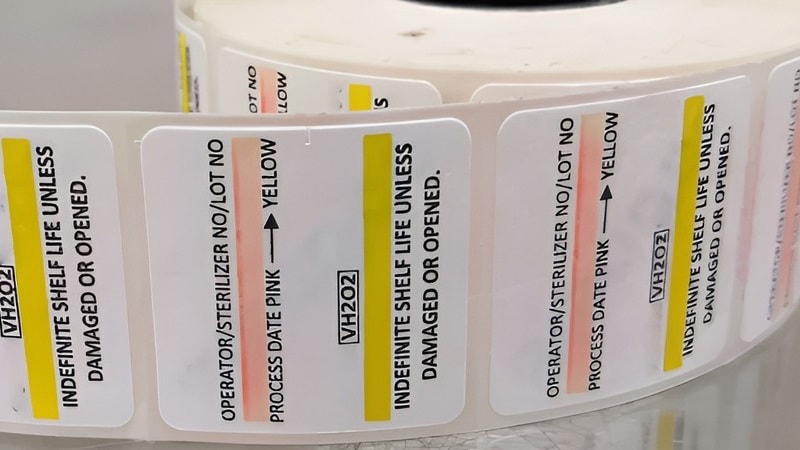

- Pharmaceuticals: Protect drugs and medical supplies with invisible UV codes and verification marks.

- Luxury goods: Block counterfeiting with UV labels and tamper-evident seals on high-end packaging.

- Government and legal: Keep sensitive documents safe with UV-printed watermarks and hidden messages to verify authenticity.

These solutions work quietly in the background but offer a powerful shield for both brands and customers.

UV Ink vs. Other Tamper-Evident Technologies

When it comes to protecting products and packaging, businesses now have more security features to choose from. These include UV ink, holograms, and QR/NFC authentication systems. Each offers unique security measures, but they differ in how they work, their visibility, cost, and how easy they are to use.

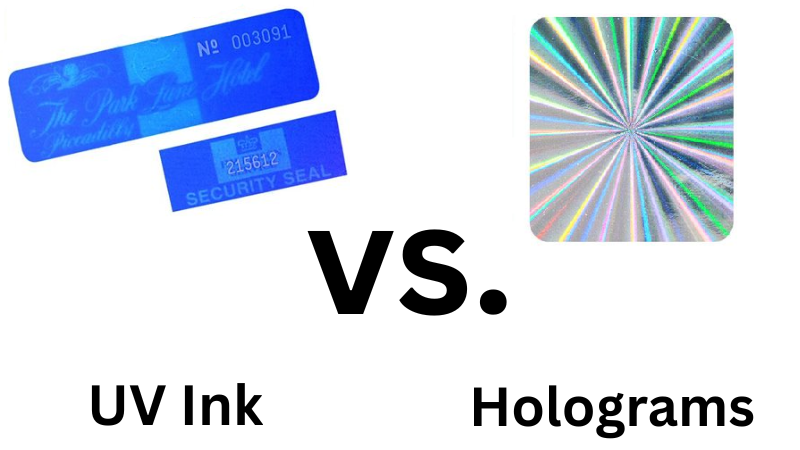

UV Ink vs. Holograms

As discussed above, UV inks offer invisible protection that only becomes visible under ultraviolet light. In contrast, holograms are always visible. They reflect light and are often used as a visual deterrent against tampering and counterfeiting.

But visible holograms can also be copied or removed. However, security ink is harder to replicate, especially when combined with tamper-evident labels or security tapes. Once applied, any tampering with the surface disrupts the ink pattern, triggering a clear tamper-evident signal.

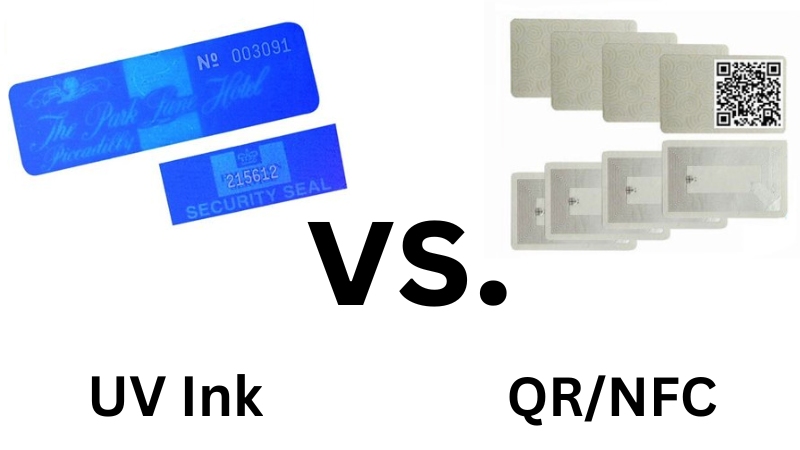

UV Ink vs. QR/NFC Authentication

QR codes and NFC tags rely on digital technology. Users scan the code or tap the tag with a mobile device to verify product details. These are effective for traceability, serialization, and consumer engagement.

Still, digital methods come with drawbacks. QR/NFC can be copied or spoofed if not backed by strong security measures. Also, they require scanning equipment or apps, which isn’t always convenient. UV security inks, on the other hand, can be quickly checked using a low-cost UV light—no internet, apps, or database access is needed.

Comparison Table: UV Ink vs. Other Technologies

| Feature / Tech | UV Ink | Holograms | QR/NFC Authentication |

|---|---|---|---|

| Visibility | Invisible under normal light | Always visible | Visible (QR), not secure by sight |

| Verification Method | UV/blacklight equipment | Visual inspection | Mobile device/app |

| Tamper-Evident | Yes, breaks on tampering | Sometimes removable | No physical tamper layer |

| Traceability | Compatible with serialization | Limited | High, system-based |

| Anti-Counterfeiting | Strong with the hidden message | Moderate, can be copied | Varies, depending on the system |

| Cost | Moderate | High | Varies (software + hardware) |

| Ease of Implementation | Easy to apply on labels, tapes, and surfaces | Needs lamination or adhesives | Requires tech integration |

| Shelf Life | Long, stable inks | Can degrade over time | Depends on tech maintenance |

Choosing the Right UV Ink Security Solution for Your Packaging

Selecting the best security ink depends on your specific packaging needs. The right setup helps ensure every security feature works as intended, is easy to verify, and supports your brand’s security applications across all product lines.

Below are key factors to consider when deciding which UV ink solution fits your packaging system.

Ink Compatibility with Material

Not all UV inks work on every surface. Some materials absorb ink differently, which affects how well the security printing stays intact. For example, plastic security labels, paper seals, and film-based tamper-evident tapes each require specific ink types.

Make sure your chosen UV ink bonds well with the label or tape material. Test samples before scaling to prevent poor adhesion or faded fluorescent marks. Most security label providers can guide you on the best ink and surface match for long-term performance.

Detection Equipment Required

Invisible UV inks need ultraviolet light or black light to become visible. So when you choose a UV ink solution, you also need to think about the right tools for detecting it. Ask yourself: Will warehouse staff, inspectors, or end users need portable UV lights? Will the checks be done in bright areas or low-light environments?

If your supply chain involves multiple checkpoints, simple handheld UV detectors might be best. In more controlled settings, like pharmaceutical plants, fixed UV light stations may work better for UV ink verification.

Volume and Scale of Packaging Needs

Consider your production volume. Larger operations may need UV ink solutions that support fast and high-volume printing. Look for options that integrate well with existing printing systems to avoid production delays.

Also, consider the security level you want across product tiers. High-value goods may need more advanced UV protection than everyday items, especially in industries like electronics or pharmaceuticals.

Customization and Working with Reliable Providers

The best results come from working with experienced security label manufacturers. They offer customized solutions, from dual-layer tamper-evident labels to invisible watermarking and fluorescent ink integration. Ask for samples that include your brand’s logo, QR code, or unique UV stamp.

Reliable providers will also support you with testing, equipment guidance, and regulatory compliance support. This helps ensure your packaging meets industry standards for product authenticity and tamper resistance.

FAQs

Is UV ink permanent?

Most UV inks are semi-permanent. They’re designed to resist fading but can be removed with strong solvents or abrasion.

Can UV ink be printed on any material?

Not all materials work with UV ink. It needs compatible surfaces like coated paper, plastic, or film-based labels for proper bonding.

How can I verify tamper-evident UV ink?

Shine a UV or blacklight on the label. Hidden marks, codes, or patterns will glow to confirm authenticity and detect tampering.

Conclusion

UV ink adds a strong layer of protection to tamper-evident tapes and labels. It makes hidden messages and signs of tampering easy to detect under ultraviolet light. This boosts product security, protects sensitive documents, and helps confirm authenticity. For businesses looking to upgrade security measures, UV ink is a smart, effective, and proven choice.

Upgrade Security with Shosky Security’s UV Ink Technology

Shosky Security’s UV ink solutions offer top-tier protection for your products. Detect tampering easily and ensure authenticity with our advanced security labels and tapes. Get in touch for personalized solutions today!