When seconds count in detecting tampering, the right security bag tape can make all the difference. Bag manufacturers face increasing pressure to provide tamper-evident solutions that balance high security with ease of use.

Whether you’re manufacturing bags for banking, logistics, or e-commerce, the security of your bags hinges on the quality of the tape used. In this article, we’ll outline the factors that bag manufacturers should consider to select the right security bag tape for bag protection.

What is Security Bag Tape?

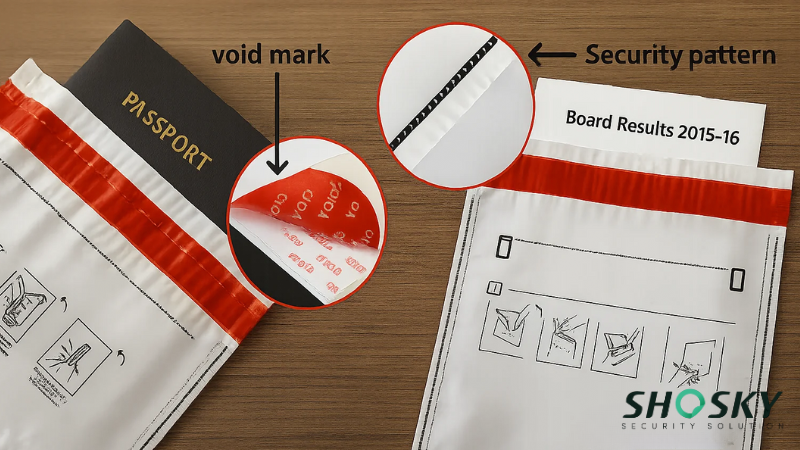

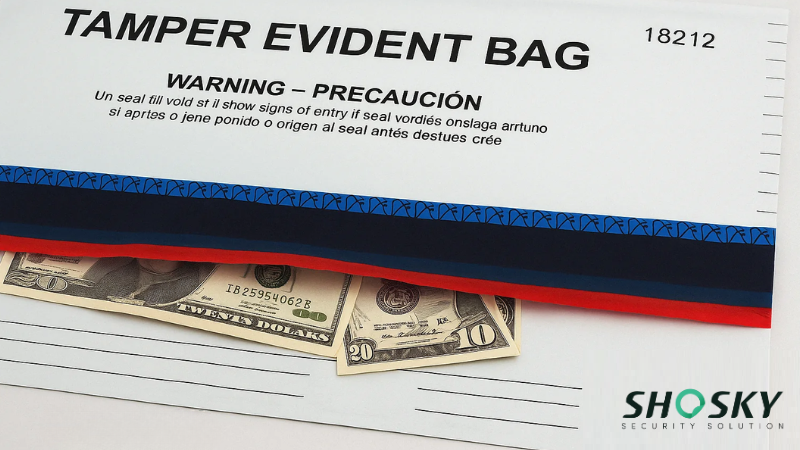

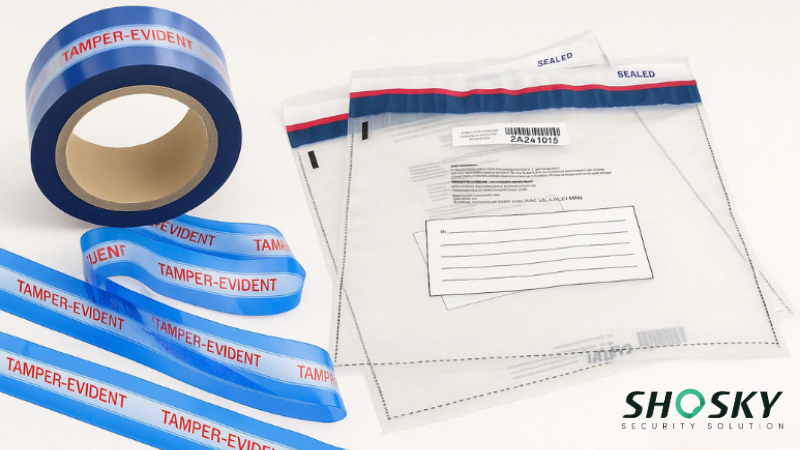

Security bag tape is a specialized adhesive strip designed with tamper-evident features that provide a visual indication if a sealed package has been compromised. It plays a critical role in protecting valuable items, confidential documents, and sensitive goods during transport and storage.

Unlike standard packaging tape, security tapes incorporate various tamper technologies, such as void-revealing patterns, hidden messaging, or color-changing properties, that make unauthorized access attempts immediately visible.

The following table shows the key differences between standard packaging tape and security bag tape.

| Feature | Standard Packaging Tape | Security Bag Tape |

|---|---|---|

| Purpose | General sealing and packaging | Protecting bags with tamper-evident security |

| Security Level | Basic adhesion only | Enhanced security with anti-tampering design |

| Applications | Everyday shipping or storage | High-risk uses: cash bags, pharmaceuticals, confidential items |

| Customization | Limited or none | Custom printing, barcodes, logos, and unique serial numbers |

| Materials & Adhesives | Standard glue for general surfaces | Advanced adhesives for plastic, paper, and fabric bags |

| Durability | Not designed for harsh conditions | Heat, cold, and moisture resistant for secure protection |

| Tampering Detection | Tampering often goes unnoticed | Clear evidence of tampering attempts instantly |

Research from the International Association of Packaging Security (IAPRI) found that packages sealed with tamper-evident security tapes experienced 64% fewer successful breaches compared to those using standard packaging tape, even when subjected to sophisticated tampering methods.

Why Manufacturers Use Security Tapes for Protection and Authentication

Manufacturers implement security tapes for multiple reasons.

First and foremost is the protection of contents against theft or contamination. A 2020 publication in Research Gate found that implementing tamper-evident security features reduced in-transit losses by an average of 27% across multiple industries.

Additionally, security tapes serve as authentication mechanisms that verify product integrity throughout the supply chain. According to a study, 78% of surveyed logistics professionals cited verifiable security features as “very important” or “critical” for maintaining chain of custody documentation.

Furthermore, regulatory compliance drives adoption in industries like pharmaceuticals. FDA reports that properly implemented tamper-evident packaging has contributed to a 58% reduction in reported product tampering incidents over the past decade.

6 Key Factors in Choosing the Right Security Bag Tape

Picking the right security bag tape goes beyond just sealing a package. These six factors help manufacturers match the right tape to the product’s risk level, material, and handling needs.

1. Level of Tamper Protection Required

Different situations call for different levels of tamper-evident technology features. Basic tamper-evident features like visible breakage or simple tear indicators are enough for low-risk applications. These tapes still act as a strong deterrent by showing signs of interference.

For medium-risk packaging, such as mailing sensitive items or handling customer returns, bag manufacturers should use security bag tapes with hidden visible void messages or color-changing elements. These features help detect tampering before the seal is fully broken.

However, high-value items or evidence bags used at crime scenes often need high-level security measures. Holographic features, destructible adhesives, or serialized tracking codes provide added assurance. They help protect the integrity of the contents and offer proof of authenticity.

2. Adhesion Strength and Compatibility with Bag Materials

Not all security bags are made from the same materials, so bag manufacturers must choose tapes based on the bag’s composition. For plastic security bags made from polyethylene or polypropylene, tapes need high-bond adhesives that ensure a lasting, tamper-evident seal even under pressure.

Paper bags and padded envelopes require a different approach. While the tape must provide security, it should also allow for easy tearing when necessary. Standard security tapes with basic tamper-evident features work well here.

For specialty or fabric-based bags, manufacturers may need heat-activated or pressure-sensitive adhesives. These tapes can offer an additional layer of tamper-evident security without compromising the look or usability of the packaging.

3. Durability in Various Environmental Conditions

Durability is crucial for bags that hold valuable items or sensitive documents. Bag manufacturers need to select tapes that withstand various environmental conditions, such as moisture or extreme temperatures.

In hot environments, such as warehouses or trucks in warm climates, standard adhesives may fail. Heat-resistant tamper-evident security tape ensures the seal holds firm and that any attempt to break it still triggers visible tamper indicators.

Cold storage bags used in food, pharmaceuticals, or medical sectors need tapes compatible with low temperatures. These tapes protect the business by preserving the security of perishable or sensitive goods from storage to delivery.

4. Customization Options for Branding and Security

Many businesses need more than just a security seal—they want their brand to be visible and secure. Custom-printed tape with logos helps build trust with customers while acting as a tamper-evident security measure against counterfeiting.

Barcodes, serial numbers, or QR codes provide traceability, especially for high-value items or regulated shipments. These additions help track products and prove chain-of-custody in case of disputes.

Covert features like UV or infrared ink markings add an extra level of security for products that need discretion. For example, luxury items or official documents benefit from these hidden features without drawing attention.

5. Cost-Effectiveness and Bulk Ordering Considerations

Budget matters, but not at the cost of compromising security. Bag manufacturers must weigh the level of protection they need against available funds. For example, using a basic tamper-evident tape on bags may work for everyday shipments, while premium options are reserved for critical assets.

Bulk ordering can help reduce per-unit costs and maintain consistency. If the same tamper-evident tape is applied across all bags, it ensures uniform security measures and prevents confusion across product lines.

Reliable suppliers who offer high-quality tapes and customization support are worth the investment. They help protect business integrity and provide consistent solutions tailored to the industry’s evolving needs.

6. Regulatory and Industry Compliance Requirements

Bag manufacturers must consider industry-specific regulations when selecting tamper-evident tape. For example, tamper-evident security bag tape used in banking or financial institutions must meet strict standards to secure documents or cash and ensure no unauthorized access.

The medical and pharmaceutical sectors have zero tolerance for contamination or security lapses. Tapes used on bags here need to comply with safety guidelines and protect patient safety from production to end-user delivery.

In e-commerce, where packages change hands multiple times, tamper-evident tape protects customer trust. Using tapes that meet courier and shipping regulations ensures secure delivery and reduces claims due to tampering.

Different Types of Security Bag Tape

Security bag tapes come in different types, each offering a unique level of tamper evidence and protection. Here’s a breakdown of the main types and how they help keep your packaging secure.

Level 1 Aluminum Backing Security Tamper Tape

This Level 1 tape is designed for general security sealing on bags. Its aluminum-backed polyester film is tough yet easy to apply, with hot melt adhesive that sticks well to most bag surfaces. Ideal for security bags across industries, it comes in jumbo rolls for converters and maintains strong performance in a wide temperature range.

Specifications and Key Features:

- Face stock: 25-micron polyester film

- Adhesive: Hot melt glue

- Liner: 25# PET release film (clear, white, red, or custom)

- Roll widths: 30mm / 35mm / 40mm / 45mm

- Roll length: 1000m (standard)

- Core size: 3-inch

- Security message: VOID / VOID OPEN / STOP

- Color: Red (custom options available)

Level 2 VOID Tamper Proof Seal Tape

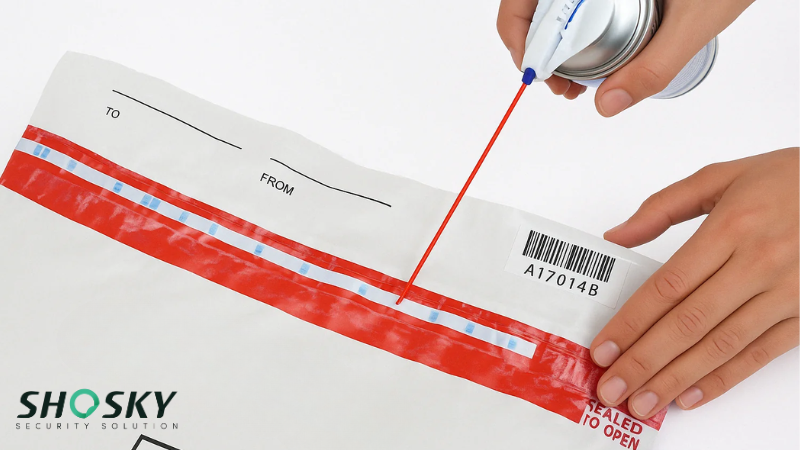

This Level 2 security tape is built for higher-risk scenarios where heat-based tampering may be attempted. Made with durable PE film, it uses thermochromic ink that permanently changes color when exposed to heat, making thermal interference instantly noticeable. The tape also reveals a bold VOID message if lifted or removed, offering a reliable layer of visible tamper evidence.

Specifications and Key Features:

- Face stock: 50-micron PE film (better heat cutting than PET)

- Roll length: 1000m (custom sizes available)

- Core size: 3-inch

- Residue type: Low or high (customizable)

- Adhesive: Non-adhesive by default

- Security features: VOID message + thermochromic ink (permanent and irreversible)

- Color: Standard blue, customizable

Level-3 Tamper-Evident Strips for High-Risk Shipments

Designed for packaging that carries valuable assets and medical equipment, this Level 3 tape adds an extra layer of advanced security. It comes equipped with thermochromic ink, which changes color under heat, while water-soluble ink reacts to liquids, offering visible evidence of interference.

Specifications and Key Features:

- Face stock: PE Film

- Film thickness: 50 microns

- Finish: Matt

- Roll width: 30mm / 35mm / 40mm / 45mm

- Roll length: 1000m or custom

- Core size: 3 inches

- Security message: Standard VOID / VOID OPEN

- Color: Orange or custom

Custom Level 4 Bag Security with UV Ink

This Custom Level 4 security bag tape offers advanced protection with features like die-cut technology, VOID message activation, and UV ink printing. It’s specifically designed to perform reliably in cold storage, refrigerated, and frozen environments, maintaining its integrity across temperatures from -40°C to +80°C.

Specifications and Key Features:

- Face Stock: Polyester Film

- Film Thickness: 25 microns

- Roll Width: 30mm / 35mm / 40mm / 45mm

- Finish: Matt

- Adhesive: Hot melt glue

- Liner: 25# PET release film

- Security Message: Standard VOID/VOID OPEN/STOP

- Color: Red, Green, or custom

How to Integrate Security Tape in Bag Production

Security bag tapes come in different types, each offering a unique level of tamper evidence and protection. Here’s a breakdown of the main types and how they help keep your packaging secure.

Step 1: Select the Right Tape and Application Method

Start by choosing the tamper-evident tape that fits your bag type and production volume. Matching the application method with your production needs reduces rework, especially when scaling production or switching to a new tape type.

Manual application works well for short runs or custom orders, while automated machines are better for large batches. From there, decide between heat-sealed or pressure-sensitive tapes—each suited for different environments. Heat-sealed options are more secure and ideal for crime scene or medical bags, while pressure-sensitive tapes are quicker to apply and better for general use.

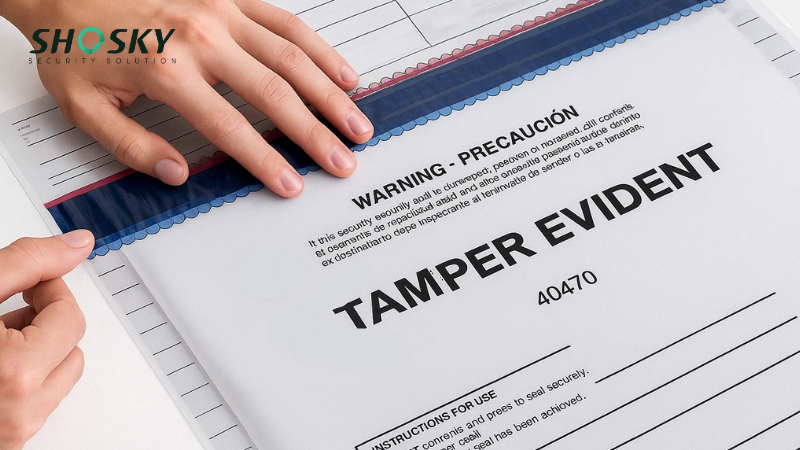

Step 2: Prepare Bag Surfaces for Bonding

Proper surface preparation is key to strong adhesion. Make sure the bag surface is dry, clean, and free of dust, oil, or coatings. Adhesives can’t bond properly on dirty or textured surfaces, which leads to tape lifting or failing under pressure.

Follow the tape supplier’s prep guidelines, especially for difficult materials. Depending on the adhesive, curing time may vary—some tapes stick instantly, while others need several minutes to set. Skipping this step can compromise the whole tamper-evident seal.

Step 3: Add Tamper-Evident and Custom Features

Once you’ve nailed the base application, move on to security features. Void messages that appear when the tape is peeled are standard. For higher security, holographic tapes or tapes with layered effects make copying harder and add visual impact.

You can also add custom printing to the tape, like serial numbers, QR codes, barcodes, or logos. These features don’t just brand the product; they make it easier to track bags and detect tampering attempts across different stages of handling.

Step 4: Set Up Production for Smooth Tape Application

Adjust your machines or workstations to handle the specific tape you’re using. This includes calibrating for tape width, pressure settings, and alignment. Wrinkled or uneven tape can weaken the tamper-evident effect or interfere with printed messages.

A well-tuned setup cuts down on waste and keeps production moving. Missed seals, wasted tape, or poor application can all increase cost and delay orders. Efficient tape handling also helps keep your tamper-evident bags consistent in quality.

Step 5: Test Tape Performance and Adhesion Strength

Before running full batches, test the tape under different stress conditions—peeling, heat exposure, moisture, and physical tampering. This ensures the void message shows up clearly, and the seal won’t fail when handled or shipped.

Include performance checks in your quality control routine. Regular peel tests or retention checks help spot weak seals early. This is especially important for bags used in harsh conditions or for high-value contents like electronics or medical gear.

Step 6: Tackle Common Problems Early On

Misaligned tape is one of the most common issues. It can look unprofessional or reduce the tape’s effectiveness. Add guides or alignment tools in production to fix this. Keeping machines calibrated also helps apply tape straight every time.

If ink fades or adhesives don’t stick, review your storage conditions. Tape should be stored in cool, dry areas, away from sunlight. Use UV-resistant ink if your bags are exposed to light or stored for long periods. These small adjustments can prevent big issues later.

Security Bag Tape vs. Other Security Sealing Methods

To use tamper-evident tape effectively during bag production, it’s important to follow a step-by-step process that ensures secure sealing and consistent quality. Here’s how to smoothly integrate security tape into your bag manufacturing workflow.

How Security Tape Compares to Labels and Seals

Security bag tape provides full-surface coverage, which makes it more effective at exposing tampering attempts. Unlike small labels or seals, the tape creates a complete tamper-evident closing with clear indicators like a visible void message when peeled.

On the other hand, tamper-evident security labels are ideal for sealing cartons or electronics. However, they don’t offer the same level of hold or enhanced security for flexible bags. Similarly, plastic and metal security seals are good for larger containers but can’t show detailed evidence of subtle interference.

When to Use Bag Tape Over Built-In Security Features

Many security bags include built-in features like permanent closures or tear-off strips. These are useful, but once sealed, they can’t be reused or easily customized. Tamper-evident tape, on the other hand, gives bag manufacturers more flexibility and control over sealing processes.

Use tamper-evident tape when you need:

- Extra branding or tracking with serial numbers or barcodes

- Strong adhesion to different bag surfaces

- An additional layer of protection for high-risk content

- Easy-to-apply sealing in both manual and automated settings

- Clear tamper-evident signs with VOID patterns or color change

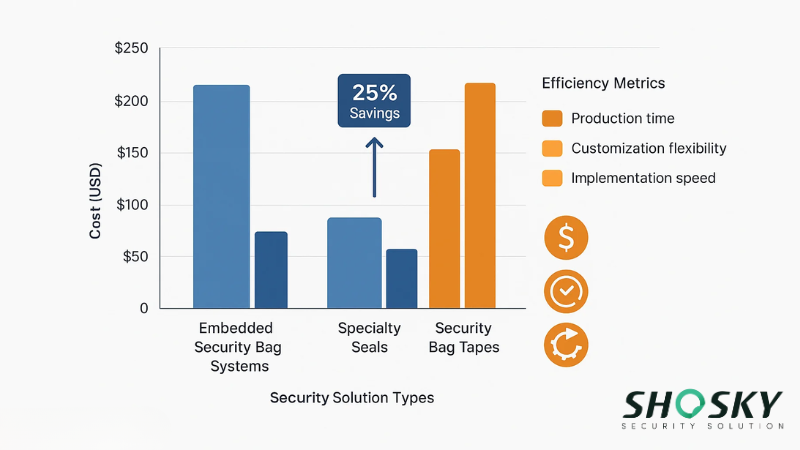

Cost and Efficiency Considerations

Compared to bags with embedded security systems or specialty seals, security bag tapes are often more affordable and adaptable. They don’t require custom molding or special bag designs, which helps reduce production time and cost.

At the same time, tapes with tamper-evident security features provide high protection standards. They’re a cost-effective way to maintain integrity, meet industry security measures, and reassure your customers that their items are well protected.

FAQs

How do I know if a security tape is high quality?

It should leave a visible void message or show damage when tampered with. It should also stick well without peeling.

Can security tape be removed without detection?

No, it leaves clear signs of tampering, such as void messages or broken pieces.

What’s the best tape for securing confidential documents?

Void tapes or self-adhesive tapes with hidden messages are ideal, as they show tampering clearly.

Conclusion

To conclude, bag manufacturers should not overlook the importance of selecting high-quality security bag tape. Prioritizing features such as tamper-evident messages and durability enhances product protection. By choosing the right tape, manufacturers can guarantee secure and trustworthy packaging for their customers.

Shosky Security’s Security Bag Tape for Bag Manufacturers: Unmatched Protection

For reliable, tamper-evident security, trust Shosky Security’s security bag tape for bag manufacturers. Our high-quality tape ensures your packaging is safe from tampering. Contact us to learn more about our secure solutions.