Businesses rely on security labels to track products, prevent tampering, and ensure compliance. But these labels often face extreme conditions, including heat, cold, chemicals, and friction. And these conditions can cause labels to fade, peel, or lose their adhesive strength.

A failing label can lead to lost assets and security breaches. So, to maintain protection, businesses must invest in durable tamper evident solutions and know how to extend the lifespan of security labels in harsh environments. This guide covers the best ways to enhance security label longevity through proper material selection and maintenance.

What Are Security Labels?

Security labels are tamper-evidence labels used to protect products, equipment, and sensitive assets. They help prevent tampering, counterfeiting, and unauthorized access. Many industries rely on them to ensure safety, authenticity, and regulatory compliance.

These labels come in different types, each designed for specific security needs. The right label depends on the level of protection required and the environmental conditions. Common types include:

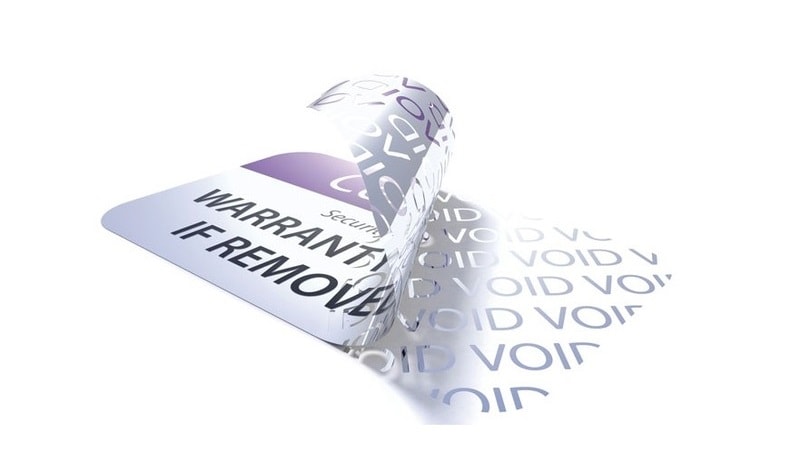

- Tamper-evident labels: Show visible signs of tampering when removed or altered.

- Void labels: Leave a “VOID” message or pattern on the surface when peeled off.

- Holographic security labels: Use unique holograms to prevent counterfeiting.

- RFID and smart security labels: Contain embedded chips for tracking and authentication.

Security labels are exposed to harsh conditions that can weaken their effectiveness over time. Factors like temperature extremes, moisture, or UV radiation can cause fading, peeling, or complete failure. So, understanding these challenges is essential for ensuring that security labels remain intact for long.

Key Environmental Factors That Reduce Security Label Lifespan

Factor 1: Temperature Extremes

Extreme heat and cold can damage security labels. High heat can melt adhesives. And this makes labels peel or slide. Cold temperatures can make adhesives brittle.

This leads to cracking. Material expansion and contraction also occur. This stresses the label. Labels may become unreadable or fall off. Labels used in industrial settings, warehouses, or outdoor applications often face these risks.

Factor 2: Humidity and Moisture on Label Adhesion

Humidity and moisture weaken label adhesives. Water can seep under the label. This causes the adhesive to fail. Labels may bubble or peel. Moisture can also damage label materials.

Ink may run or fade. Paper labels can warp or disintegrate. Industries like food production, pharmaceuticals, and outdoor logistics commonly experience these challenges.

Factor 3: UV Radiation and Label Degradation

UV radiation from sunlight damages label materials. It fades colors and weakens the label surface. Some materials become brittle. Adhesives can break down. This reduces the label’s lifespan.

Outdoor labels, especially those used in construction, shipping, and vehicle tracking, face a higher risk of UV damage, which reduces their lifespan and effectiveness.

Factor 4: Physical Abrasion from Handling and Transportation

Handling and transport cause physical wear. Labels rub against other surfaces. This leads to scratches and tears. Labels may peel at the edges. Rough handling can also remove parts of the label. And this makes the label unreadable.

Packages dropping or shifting worsens this problem. Industries that rely on heavy equipment, logistics, and industrial manufacturing frequently deal with label wear due to abrasion.

Factor 5: Chemical Exposure and Corrosion Risks

Chemicals can dissolve or damage label materials. Cleaning agents and solvents are common culprits, too. Some chemicals corrode adhesives.

And this causes labels to detach. Industrial environments often have chemical exposure. This poses a significant risk to label integrity.

How to Choose the Right Security Labels for Harsh Environments?

Here’s a table summarizing the key factors for choosing the right security labels for harsh environments:

| Factor | Details | Best for |

|---|---|---|

| Material Selection | Use polyester, polyimide, or metal tags | Extreme temperatures, chemicals |

| Adhesives | Permanent for durability, removable for flexibility | Moisture-prone and industrial areas |

| Protective Coatings | UV-resistant and moisture-proof laminates | Sunlight, water, abrasion |

| Printing Method | Thermal transfer printing for longevity | High-durability applications |

| Customization | Custom labels with barcodes and branding | Asset tracking, industry needs |

Every industry has unique needs. That’s why custom harsh environment labels are also available. These engineered labels can handle specific challenging conditions. For durable prints, you can consider thermal transfer printing. This option works well for long-term visibility.

Ways to Extend the Lifespan of Security Labels in Harsh Environments

Choose the Right Type of Security Label

Selecting the right security label is essential. Not all labels can withstand harsh environment. So, it’s important to choose one designed for the specific environment. Using the wrong type can lead to premature failure, reducing protection and increasing replacement costs.

The custom harsh environment labels are designed to resist damage. Weatherproof labels withstand rain and snow. Water-resistant labels handle moisture.

Lastly, UV-resistant labels protect against sunlight. Choosing the right label upfront saves time and money. Also, it ensures that it can perform its intended function.

Opt for High-Quality Materials

The durability of security labels depends on the materials used. Choosing the right materials ensures they withstand harsh environments without fading, peeling, or becoming unreadable. When selecting materials, focus on both the substrate material and adhesive material to ensure long-lasting performance.

- Substrate Material: The face material should be resistant to tearing, moisture, and chemicals. Polyester, polyimide, and vinyl are common choices for harsh environments due to their durability. Metal tags offer extra strength in extreme conditions where plastic or paper labels may fail.

- Adhesive Material: The adhesive determines how well the label sticks to both smooth and rough surfaces. Permanent adhesives are best for long-term use in high temperatures, moisture, and abrasion-prone areas. Removable adhesives provide flexibility for temporary applications.

By selecting the right substrate and adhesive materials, security labels remain intact, readable, and reliable in demanding environments.

Proper Application Techniques

Even the best security labels can fail if applied incorrectly. So, proper application is key! It prevents early label failure. Start with a clean surface. Remove dirt, dust, and grease using a suitable cleaner. A contaminated surface weakens adhesion, causing the label to peel or detach over time.

Apply even pressure when placing the label. Press firmly across the entire surface to ensure full contact. This strengthens the bond and reduces the risk of lifting or curling. Avoid air bubbles, as they can weaken adhesion. Smooth out the label carefully to eliminate trapped air.

Lastly, always follow the manufacturer’s instructions. Each label type has specific requirements for optimal performance. Proper application ensures the label stays secure and provides lasting protection.

Protective Coatings

Protective coatings extend label life. They shield the label from damage. There are different types of coatings exist including laminates, varnishes, and overcoats.

- UV-Resistant Coatings: Prevent fading and degradation from sun exposure.

- Waterproof Laminates: Shield labels from humidity, rain, and water contact.

- Abrasion-Resistant Overlays: Reduce the impact of friction and rough handling.

Applying them ensures that labels remain legible and secure over time. So, carefully consider coatings that resist specific environmental factors.

Regular Monitoring

Periodic inspections help detect signs of wear before labels become unreadable. Labels in high-traffic areas may experience faster degradation due to physical abrasion and exposure to elements. Routine checks ensure that security features like void patterns, holograms, and RFID chips remain intact.

- Look for fading, peeling, or damage on labels exposed to UV rays and extreme temperatures.

- Replace labels that show signs of wear to maintain security and traceability.

- Use thermal transfer printing for barcodes and text to prevent smudging over time.

Regular maintenance extends label life and ensures that security measures stay effective in harsh environments. A proactive approach prevents costly replacements and security breaches due to unreadable or missing labels.

Common Mistakes to Avoid When Using Security Labels in Harsh Environments

Applying Labels in the Wrong Conditions

Applying labels on surfaces that are too hot or too cold is a common error. This impacts adhesion. Adhesives are designed for specific temperature ranges.

Applying labels outside these ranges weakens the bond. Hot surfaces can cause adhesives to melt. Cold surfaces can make them brittle. The applied surface temperature is crucial for proper adhesion.

Consider the environment’s temperature. If labels are applied in direct sunlight, the surface may be too hot. If applying labels in a freezer—the surface may be too cold.

Always check the surface temperature before application. Use a thermometer if needed. Applying labels in the wrong conditions leads to premature failure. This wastes time and resources.

Using Generic Labels

Generic security labels or tamper evident labels are not designed for harsh conditions. They lack the necessary durability. They may not withstand extreme temperatures or chemical exposure. They may also degrade under UV rays. Using generic labels leads to early failure. This compromises security and traceability.

Specific environmental factors require specialized labels. For outdoor use, choose UV-resistant labels. For industrial settings, select chemical resistant labels. If labels face high heat, use heat resistance labels. Each environment has unique challenges. Using the right label ensures it performs as intended. Generic labels fail to provide adequate protection.

Ignoring Manufacturer Instructions

Ignoring manufacturer instructions is a frequent mistake. Manufacturers provide guidelines for optimal performance.

These include application techniques and storage conditions. Following these instructions ensures the label functions correctly. Ignoring them leads to problems.

Labels may not adhere properly. They may also degrade faster. Manufacturer instructions are based on extensive testing.

Recommended conditions include temperature and humidity ranges. They also include surface preparation. Ignoring these recommendations leads to label failure. This can result in security breaches.

Storage and Maintenance Tips for Long-Lasting Security Labels

Proper storage keeps security labels effective for longer. If labels are not stored correctly, they may lose adhesion, fade, or become brittle before application. To prevent this, labels should be kept in a controlled environment with stable temperature and humidity levels.

It is best to keep labels in their original packaging until use to prevent contamination. Avoid stacking heavy objects on them, as bending can reduce adhesion and security performance. Handling labels with care prevents damage before application.

Handling security labels with care is equally important. Avoid touching the adhesive side because the oils from fingers can reduce their ability to stick properly to both the applied surface and coated layers.

Proper storage, handling, and maintenance extend label life, keeping security features reliable in challenging conditions.

FAQ

What is the best type of security label for high-humidity environments?

Use labels made from moisture-resistant materials like polyester or vinyl. Choose waterproof adhesives designed to maintain a strong bond in damp conditions.

What are the best adhesives for extreme temperatures?

Select acrylic adhesives for high heat resistance and long-term durability. Use rubber-based adhesives for cold temperatures, as they remain flexible and maintain adhesion in freezing conditions.

How often should security labels be inspected and replaced?

Inspect labels regularly, especially in harsh environments. Replace them when you see damage or fading.

Conclusion

Security labels play a crucial role in preventing tampering. However, harsh environments can compromise their effectiveness. Businesses can extend the lifespan of security labels by carefully choosing materials and adhesives.

With the right approach, security labels will continue to provide reliable protection even in the most challenging environments.

Need Reliable Security Labels? Shosky Has Got You Covered

For reliable and long-lasting security labels, trust Shosky Security! Whether you need security labels, void labels, or ultra-destructible labels ― we provide industry-specific solutions to meet your needs. Contact us today to find the perfect security labels for your business.