That all changed in 1925, when adhesive tape was invented. What started as a simple solution for auto body painters quickly evolved into one of the most versatile tools in homes, industries, and packaging lines around the world.

Today, adhesive tapes aren’t just easier to use. They offer cleaner, faster, and more efficient bonding solutions without damaging surfaces or slowing down production. In this article, you’ll discover how adhesive tapes work, explore the materials and adhesive types behind them, and learn how they’re made, from polymerization to the final spool.

Common Adhesive Tape Materials

There are different classes of adhesive tapes, such as water-activated, heat-activated, and pressure-sensitive adhesives (PSA).

The PSTC or Pressure Sensitive Tape Council denotes PSAs as a continuous flexible strip of paper, cloth, metal, or plastic coated on one or both sides with a permanently tacky adhesive at room temperature that adheres to various surfaces. It only requires light finger pressure with no change of phase on a roll form.

What differentiates a PSA tape from other kinds of adhesives is that activation by any solvent, water, or even heat is no longer needed just to exert a strong adhesive force towards diverse materials like paper, plastic, glass, wood, or even metal.

Although the adhesive used on PSA tapes might seem likely, as they all adhere well, are tacky, and resist stress, it turns out they are pretty different. There are advantages and disadvantages for each class of tape, whether it is rubber, acrylic, or silicone-based adhesives.

Rubber

Rubber is the oldest kind of adhesive made from natural rubber, but it needs resin in order to make it into an adhesive. Rubber adhesive systems are usually used for indoor applications with low-stress requirements, including masking tapes, duct tapes, carton sealing tapes, and laminating tapes.

They generally adhere well to low surface energy substrates and are formulated for excellent removability. Moreover, they are not tacky by nature. Therefore, it is necessary to add tackier resins to produce them. Here are the two main categories of rubber adhesives:

- Natural Rubber

These natural rubber adhesives typically have a high molecular weight with long polymer chains. They usually adhere to low surface energy (LSE) substrates and portray clean removability and good shear.

Apart from being often less expensive, natural rubbers have an initial high tack, unlike acrylic, which needs time to cure. However, they are poor when it comes to temperature resistance and aging properties.

- Synthetic Rubber

Synthetic rubber is commonly known as a “hot melt” adhesive. This adhesive tape material is thermoplastic with a short polymer chain or low molecular weight. It is more customizable compared to natural rubber adhesives for better LSE adhesion with more tack and some temperature or UV aging resistance.

Since it offers higher adhesion and shear resistance, synthetic rubber is perfect for sealing cartons and packages.

Acrylic

Interestingly, the weak features of rubber adhesives are bested by colorless acrylic adhesives. This is because acrylics are stable to oxidation and exposure to UV light, and their stability in oxidation provides years of protection against UV light.

Acrylic adhesive systems are used for indoor and outdoor applications that need more permanent, long-term bonding solutions. Acrylics are naturally tacky, and the tackier feature is beneficial to boost their quick-stick properties. However, acrylic adhesives cost about twice as much as rubber adhesives.

Also, they are not quite as good as natural rubber when it comes to harder-to-adhere surfaces, plus they require a significant period to cure. Here are the two main types of acrylic adhesives:

- Solvent Acrylic

Solvent acrylic adhesives got their name because their polymer grains dissolve in a solvent. Generally, these PSAs do not adhere well to LSE substrates, but they showcase better property retention than rubber under several circumstances.

- Emulsion Acrylic

These water-based PSAs contain spherical particles surrounded by a surfactant in a water carrier. Emulsion acrylics are generally less expensive and more eco-friendly than solvent acrylics.

Still, they do not provide good moisture resistance because of their water-based properties, which leads to solvent acrylics being preferred for critical applications.

Silicone

Silicone adhesives offer many years of service life, but they are considered the most expensive kind of adhesive. They possess a very high temperature resistance and can handle harsh environmental conditions.

Despite silicone adhesives’ bonding strength, they are often incorrectly perceived as having deficient sticking capability due to their low initial bond strength.

Tapes with silicone adhesive solutions are generally utilized for critical applications where adhesives are exposed to extreme temperatures or environments. This includes the electrical industry, where the temperature is a difficult feat.

Moreover, they cost twice as much as acrylics, but similarly to the latter, they can also be used against the skin, making them widely used for medical applications.

Adhesive Tape-Making Machine Introduction

Adhesive tape was invented in 1925 as a painter’s masking tape for auto body shops, which led to transparent tape designed to seal the cellophane wrap used by the food industry. Then, the adhesive tape was introduced as a household item, and the idea just stuck.

The science of the adhesive tape manufacturing process starts with polymerization. This means the structure of adhesives and the polymers or molecule chains are combined in the chemical process. In the aftermath, the adhesives are prepared to be applied quickly and very thinly to the preferred backing material.

But how this takes place entirely depends on the adhesive.

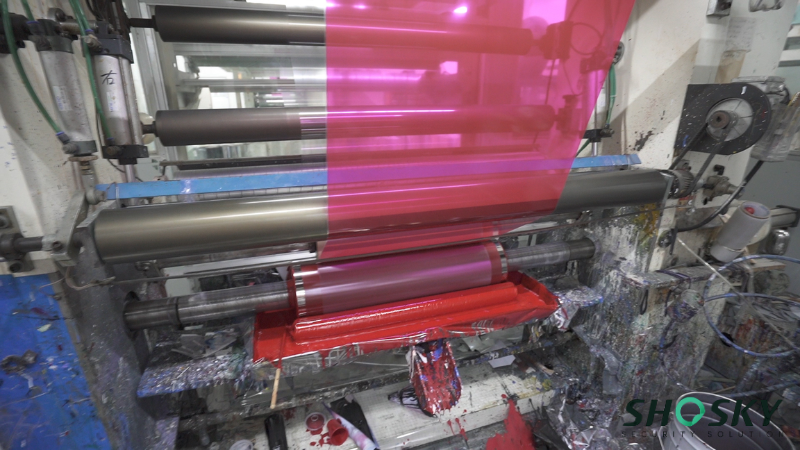

In the process of adhesive tape making, the adhesive mass, backside treatment agent, primer, and other important components are either in-house manufactured or purchased.

Then, a tape base element is coated using these materials, with the solvent removed by drying, and then wound around in the form of a roll. The coated roll is further cut to the desired width and then packed.

In addition, the transfer of the PRTR (Pollutant Release and Transfer Register) chemicals other than the solvents (both liquid and solid) used for the base material, adhesive mass, primer, backside treatment agent, and so on also took place from the production process such as coating, rewinding, and slitting of tape rolls.

Adhesive Tape Manufacturing Process

Here is a general step-by-step process of adhesive tape making:

1. Polypropylene Film in Unwinder

Whether the production floor is making shipping tape, electrical tape, and so on, the adhesive tape manufacturing process starts with rolls of a plastic film called polypropylene.

The rolls go on a machine called the unwinder. Workers then position a strip of adhesive splicing tape along the end of each row to enable them to connect one roll after another, creating an uninterrupted feed to the production line.

2. Unwinding Rolls onto Splicing Tape

Once the roll unwinds completely, its end sticks onto the splicing tape at the beginning of the next row. When that rolls unwound, its end will stick to the beginning of the next, and so on.

3. Automatic Tension Adjuster

An automatic tension adjuster makes sure that the machine pulls the film evenly to prevent it from ripping.

4. Application of Solvent

The unwinder also applies a solvent to the film surface. This prevents the film from sticking while unrolling. In order to transform this film into tape, the machine coats one side with a hot adhesive known as hot melt, which is made from several ingredients.

The synthetic rubber gives it flexibility, a UV protector keeps it from drying and discoloring, while an antioxidant prevents aging. The addition of synthetic resin makes it sticky, while adding pigmentation oil provides a choice of color, like a tan, for packing tapes.

5. Preheated Holding Tank

Next is loading the hot melt into a preheated holding tank, which keeps it at a temperature of 390 degrees Fahrenheit to prevent the tape from hardening. The tank pumps adhesive to a machine called the blower. Then, wipe away the excess and roll the film.

6. Use of Cooling Roller

A cooling roller that went on top immediately hardened it. A computerized sensor ensures there is an even coat of adhesive. Otherwise, it automatically signals the pump to adjust the output if there is not. If the adhesive tape is double-sided, a separating layer is also inserted when winding.

Afterward, the process begins again to coat the other side of the adhesive tape.

7. Rewinder Machine

On a rewind machine, roll the tape into spools. Remember the unwinder that spliced the rolls together? The rewinder machine unsliced them. When all are filled, a knife separates the adhesive tape at the splice point so that winding can begin on the next phase.

8. Slitter Machine

The tape on just one of the manufactured spools would run an average length of 85 football fields. The spool speeds up a row of sharp razor blades called the slitters, which divide the five-foot-wide tape into several strips. A shipping tape, for instance, is almost 2 inches wide, so you can get 31 strips per spool.

9. Finished Tape Rolls

Each strip winds on a tilted cardboard core, and its end is sealed with the tab. The length of tape per roll varies according to the customer’s specifications. As the machine ejects the finished tape rolls in the next batch of cardboard cores, it is off to the packaging department.

10. Quality Control Check

Before packing and shipping, manufacturers make sure that their adhesive tapes pass through a quality control check as they test the sample roll from each spool.

For instance, in one test, they unroll the tape’s sticky side up and release a tiny stainless steel ball down an incline, measuring how far the ball rolls before it sticks and comes to a stop. The ball has to adhere within a certain distance to pass the test. The stopping distance varies depending on the type of adhesive tape.

Other Materials Used for the Backing of Adhesive Tapes

Adhesive tapes and films differ primarily in the carrier or backing material used, which significantly affects their properties and applications. Understanding the most common types of carriers can help in selecting the right adhesive tape for specific tasks.

The table below summarizes the various backing materials and their key characteristics:

| Backing Material | Description / Key Features |

|---|---|

| Paper | Known as flatback tape; features a paper backing. |

| Cloth | Woven cloth or fabric layer; provides reinforcement, strength, and heat resistance. |

| Felt | Non-woven material; applied to prevent scratching on substrates. |

| Foam | Backed with foam and liner-protected adhesive; used for sealing, mounting, and weather-stripping. |

| Metal Foil | Includes aluminum, copper, and lead; resists humidity, heat, and flames; used for sealing and PCB production. |

| Plastic Film/Polymer | Thermoplastics and thermosets; can be layered and combined with paper or aluminum for diverse uses. |

| Polyethylene Terephthalate (PET) | Also known as Mylar; polyester film or laminate backing for durability. |

| Polyimide | Heat-resistant tape with polyimide film and silicone adhesive; ideal for flexible circuit manufacturing. |

| Polyvinyl Chloride (PVC) | Vinyl backing that resists wear, abrasion, and weathering. |

| Glass/Fiberglass | Offers durability and resistance to shrinking, burning, and rotting; suitable for extreme conditions. |

| Filament | Also called strapping tape; reinforced with filaments for bundling and shipping irregularly shaped items. |

Each of these materials plays a vital role in determining the tape’s suitability for tasks such as sealing, bundling, insulation, or electronic applications. Choosing the right backing can greatly improve performance and durability in both industrial and commercial settings.

FAQs

1. Are acrylic adhesives good for outdoor use?

Yes, acrylic adhesives are great for outdoor use due to their UV and oxidation resistance.

2. How is adhesive tape quality tested?

Manufacturers roll a steel ball on the tape and measure how far it travels before sticking.

3. What are the common uses of rubber adhesive tapes?

Rubber tapes are often used for masking, packaging, and sealing low-stress, indoor applications.

Conclusion

From its invention in 1925 as a simple painter’s tool to its widespread use across industries today, adhesive tape has become an essential material in modern life. With a wide range of adhesive types, such as rubber, acrylic, and silicone, and backing materials suited for different applications, tape technology has evolved to meet diverse needs.

The detailed manufacturing process behind every roll ensures strength, flexibility, and precision. Whether for packaging, medical use, or electronics, adhesive tapes offer efficient and reliable bonding solutions that continue to support innovation across sectors.

Get Your Adhesive Tape From Shosky Today!

If you wish to find a reliable adhesive tape manufacturer to support your business, Shosky is a good choice. Check out with us for affordable and high-quality adhesive tapes today!