Production

Home

Production

Optimized Production

Taking advantage of modern machinery and automated processes, Shosky Security is able to manufacture at high levels of efficiency and process VOID printing 6 times faster than most of our peers.

Shosky Security Figure

15 +

Years of Experience

5,000 ㎡

Plant Area

7

Production Lines

3,500,000 ㎡

Annual Production

Our Efficient Production Process

Plate Making

The printing plates are embossed with the desired VOID message designs which will be used for printing on the facestocks.

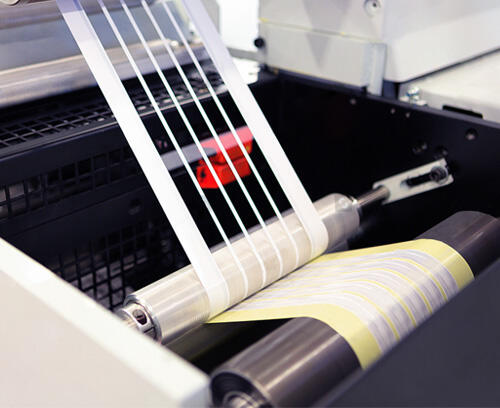

VOID Printing

Using the right amount of pressure, the nickel plates are pressed on the facestocks, imprinting the design on the strips. The rolls are then set to ensure the design stays on the surface.

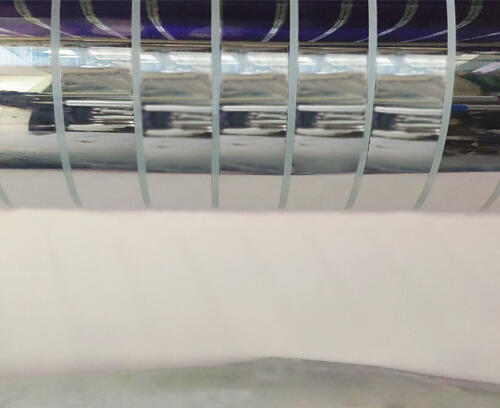

Protective Layer Adding

A layer of protective chemical ink is printed on the surface of the facestock, the layer assists in leaving the clear VOID message when tampered with.

Color Applying

Customers can specify colors (i.e., matte green, dull red, etc.) for the facestock. We also give suggestion on color selection based on the carton color. While the labels seem less obvious and just looks like a normal label, the ones who want to tamper the products will leave the using trace unconsciously.

Adhesive Coating

A coat of pressure-sensitive acrylic adhesive is applied on the materrial, which is followed up by the release liner at the bottom of the materrial. The adhesive is formulated based on intended use, with the release liner preventing the adhesive from sticking into unintended surfaces.

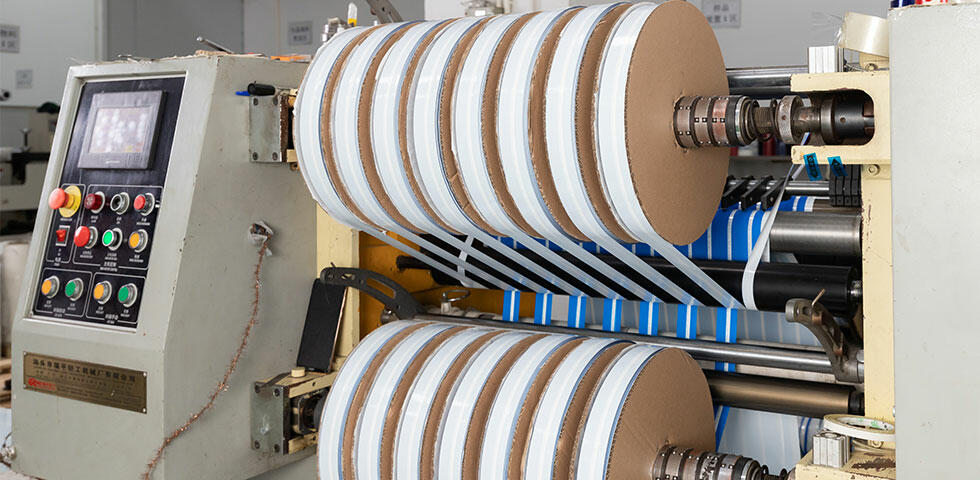

Slitting

Shosky Security has the custom slitting capabilities to convert product widths according to your specific requirements. Our state-of-the-art slitting capabilities allow us to slit the tamper evident products with a tolerance of +/- 1/64" or tighter depending on the material type.

Die Cutting

High-powered automated die-cutting machines cut through the labels, segmenting the labels per desired dimensions. The efficiency of the die-cutting machines reduces waste during production and ensures accurate measurements for use.

Fully-Automated Workshop

Shosky Security’s 5,000-square meter facility houses 7 automated production lines producing up to 3.5 million sq. meters of tamper evident security solution products, allowing for smooth and efficient production.