Even well-run factories face inventory shrinkage. According to the most recent stats, internal theft and diversion cost global manufacturers over $50 billion annually. Many of these losses come from unnoticed stock movement between shifts, unsecured storage areas, and weak tracking during internal transfers.

Adding tamper-evident seals and tapes to critical points in your operation can help close those gaps. These tools don’t just flag breaches—they also reinforce accountability and reduce reliance on manual checks. In this article, we will discuss how these products work, when to use them, and why they’re becoming essential for manufacturing plant security.

Why Internal Theft & Diversion Happens: Understanding the Threat

Internal theft and diversion often start at security blind spots in the production process. In many manufacturing plants, raw materials, components, and finished products move between departments without tight inventory control.

This lack of visibility can affect safety stock levels, disrupt order fulfillment, and inflate inventory costs without immediate signs of loss.

Insider threats grow when visibility is limited. Unlike external theft, these cases involve employees who already have access to critical areas—such as storage rooms, transit cages, or quality control zones.

A 2022 National Retail Federation report found that 44% of businesses see internal theft as a rising issue, especially in operational settings. In manufacturing, this often means untracked losses and tampered goods.

Thieves usually target high-value items like electronic parts, tools, or components in transit. Items between departments or in temporary storage are more exposed.

Without tamper-evident security seals, they can be stolen or swapped with counterfeit products. This causes inaccurate cycle counting and unreliable records and forces plants to hold more safety stock, raising warehouse space and storage costs.

Digital tracking helps, but it isn’t enough. A 2023 Forrester study found that 37% of manufacturers rank physical inventory loss as a top risk.

Tamper-evident solutions provide quick, visible signs of access breaches. When placed at key points—like bins, cages, or carts—they strengthen risk assessment and help maintain inventory control.

What Are Tamper-Evident Seals and Tapes?

Tamper-evident seals and tapes are physical security solutions designed to make any unauthorized access immediately noticeable. These products are used across the manufacturing sector to protect access points, equipment, and inventory.

When applied correctly, they leave visible marks or messages if tampered with, making unauthorized actions easy to detect.

These products are an important part of any inventory control strategy. While software tracks numbers and movement, tamper-evident packaging solutions deal with the physical side of access. They help facilities close gaps where manual oversight isn’t always possible—like overnight shifts, cross-department transfers, or shared storage areas in the warehouse.

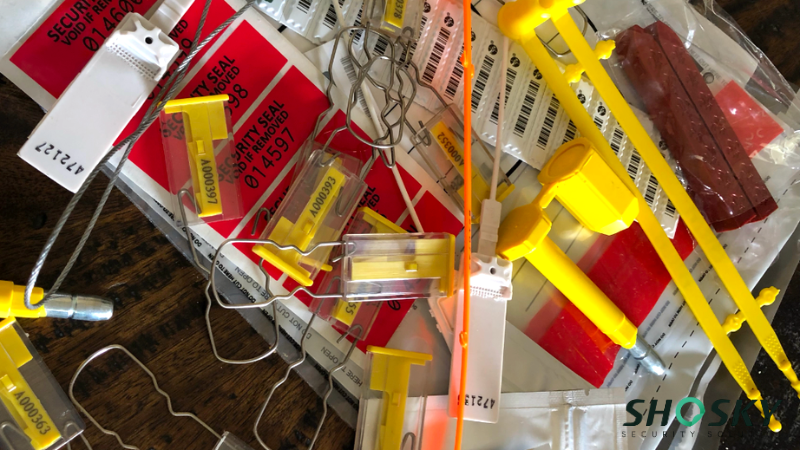

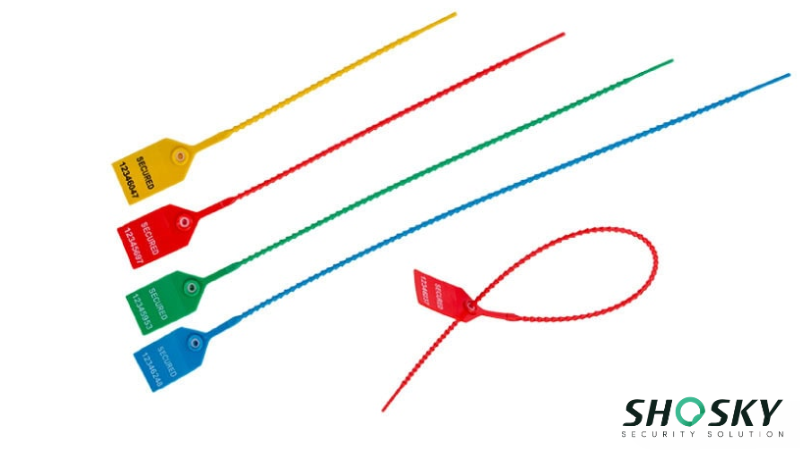

Here are the common types used in industrial and manufacturing setups:

- Tamper-evident tapes with VOID residue – Applied to packages or pallet wrap; reveal tampering by showing a “VOID” pattern when removed.

- Plastic strap seals – Used on bins, internal cages, or rolling containers; once broken, they can’t be reapplied.

- Serialized security labels – Include barcodes or numbers to track access across departments or delivery routes.

Adding tamper technologies solutions improves day-to-day visibility and strengthens accountability. For facilities dealing with frequent handling and shared access points, these solutions act as simple but effective barriers that support both warehouse management and loss prevention.

Core Benefits Beyond Tamper Detection

Tamper-evident seals and tapes do more than just reveal if something was accessed—they also strengthen key parts of your operations. Below are four ways tamper-evident solutions help improve both security and workflow across your manufacturing facility.

Psychological Deterrent Against Opportunistic Theft

The presence of a tamper-evident seal or tape often stops theft before it happens. When employees or contractors know that access points are sealed and monitored, they’re less likely to take chances.

This small layer of visible control sends a strong message that movement is tracked, and every break in the system will be noticed. In high-turnover environments, this added pressure can reduce incidents linked to insider threats.

Supports Process Integrity and Accountability

In manufacturing, many workflows involve multiple people handling the same inventory. Whether it’s raw materials being moved to the line or finished stock heading to storage, each step creates a risk.

Tamper-evident tools improve inventory control by creating clear checkpoints. When a seal is applied at one step and inspected at the next, it reinforces accountability and reduces room for error or interference.

Helps Meet Regulatory and Compliance Standards

Industries like pharmaceuticals, food processing, and electronics face strict standards around quality control and traceability. Using tamper-evident products helps meet guidelines under ISO, GMP, and FDA regulations by showing that access is monitored and controlled.

Seals and tapes provide visible, documented proof that proper handling protocols were followed, especially in audits or inspections.

New Ways Tamper-Evident Tools Are Used in Modern Plants

Manufacturing plants face risks from both internal and external sources. Tamper-evident solutions are now being used in smarter ways—from preventing product tampering during transit to blocking unauthorized access in critical zones.

The examples below show how they support key parts of the supply chain.

1. Securing Inventory Management and Outbound Shipments

Tamper-evident seals and tapes are now widely used to secure outbound packaging, especially during third-party delivery. If a seal is broken or a tape reveals a “VOID” message, it signals that the shipment may have been accessed without approval.

This gives manufacturers a simple way to track movement across the supply chain. When used with barcodes or serial numbers, these tools tie into inventory management systems and help maintain custody records, especially for high-value or sensitive items.

2. Reducing Shrink with Internal Department Transfers

Shrinkage also happens inside the facility—during transfers between departments or work zones. Sealing totes, bins, or internal containers ensures raw materials and components aren’t tampered with in between steps.

These tamper-evident tools create visible proof that the stock was untouched in the supply chain during movement. This builds accountability between teams and helps reduce errors, especially when handling safety stock or time-sensitive inventory.

3. Controlling Access in High-Risk or Sensitive Areas

Tamper-evident products are increasingly used to restrict and monitor access to critical areas inside manufacturing facilities. If someone enters without permission, the broken seal gives an immediate, visible sign of unauthorized access.

This is especially useful during audits, overnight hours, or shift changes when fewer personnel are present. Sealing equipment cabinets, tool drawers, or inspection carts during these periods helps protect assets and avoid disputes about who last accessed what.

How to Choose the Right Security Product for Your Use Case

Not all tamper-evident tools serve the same purpose. Knowing where to use which solution can help you tighten inventory control and reduce risk without slowing down operations.

Which Tamper-Evident Tool Fits Your Use Case?

Each type of tamper-evident product serves a different purpose depending on where and how it’s used. The table below gives a quick comparison to help you choose based on your inventory control needs, storage conditions, and risk level.

| Type | Best For | Key Benefit |

|---|---|---|

| Tamper-Evident Tape | Shipping boxes, pallets | Fast application; shows tampering instantly |

| Seals (Plastic/Metal) | Bins, lockers, internal containers | Stops shrinkage; enforces internal control |

| Security Labels | Individual items, storage units | Adds traceability; links to inventory records |

| Single-Use Options | High-value or regulated stock | Strong control; can’t be reused |

| Multi-Use Options | Shared tools or reusable containers | Flexible; still deters unauthorized access |

| Custom Branded | Branded goods, high-risk products | Blocks counterfeit; protects IP |

No single solution works for every scenario. Use this guide to evaluate your options based on your technology, how your products move, what risks you face, and where control matters most. Picking the right tools helps reduce loss, increase customer satisfaction, and improve supply chain performance.

Consider Material Durability in Harsh Environments

Some products need to perform in tough conditions like cold storage, heat, or dusty zones. If the seal breaks too easily or the adhesive fails, the security is gone. Always choose materials that match your facility’s real conditions.

A seal in a high-humidity area will fail differently than one in a freezer. For example, food or chemical plants often need heavy-duty options to ensure quality control. If not, you risk gaps in your inventory records and spoilage issues.

Durability also protects your intellectual property and helps avoid lost stock. A durable seal helps maintain inventory levels and supports proper order fulfillment—even in areas with repeated handling or limited oversight.

Single-Use vs. Multi-Use Tamper Indicators

Single-use seals or tapes are ideal when access should be strictly controlled. Once broken, they can’t be reused—perfect for sensitive stock, high-value items, or regulated inventory with expiration dates.

Multi-use options work better in shared environments where equipment or stock needs to be accessed multiple times. While not as secure, they still discourage tampering and help maintain order in daily workflows.

Choosing between the two depends on your inventory management goals. If you’re using ABC analysis to prioritize stock, single-use is best for A-items. Evaluate usage frequency and storage space needs before deciding.

Custom Branding and Serialization to Prevent Counterfeit Swaps

Custom tamper-evident tools make it harder for anyone to swap or fake products. Adding your logo, company colors, or a serial code builds trust and protects your intellectual property. It’s especially helpful when selling or moving high-value goods.

Serialized labels with barcodes or RFID tags can be scanned and matched to inventory records. This supports tracking, improves inventory accuracy, and helps meet customer demand faster and more reliably.

For small businesses, this kind of detail may seem complex—but it can be scaled easily. Implementing custom seals improves both warehouse management and your ability to catch risks before they affect product quality.

Real-Life Examples: Tamper-Evident in Action

Tamper-evident tools aren’t just theory—they’re actively used in management plans by manufacturers to solve real problems. Companies across various sectors are adding continuous improvements and are now using these products.

The following examples show how different facilities apply seals, labels, and tapes to protect critical points in their operations.

- Electronics Manufacturer: Uses tamper-evident seals on bins containing small, high-value parts to reduce internal theft.

- Pharmaceutical Plant: Applies serialized tape to cartons to maintain traceability and meet regulatory standards.

- Auto Parts Factory: Seals transfer carts that move components between assembly lines to prevent swaps or loss.

- Warehouse Operation: Tracks nighttime pallet tampering using VOID tapes, improving after-hours accountability.

In each case, simple tamper-evident solutions support larger inventory management goals—like maintaining stock accuracy, improving supply chain visibility, and preventing product diversion. These solutions work quietly in the background but make a measurable difference across daily operations.

FAQs

Are tamper-evident seals reusable for inventory control?

No, most tamper-evident seals are single-use. Once broken, they can’t be reapplied or hidden.

Can these tapes withstand chemical exposure?

Yes, many tamper-evident tapes are made for harsh environments and resist heat, cold, and chemicals.

How do you track seal numbers for risk assessment?

Use serialized seals with barcodes and scan them into your inventory management system for quick tracking.

Conclusion

Manufacturing plants face increasing pressure to protect assets, meet compliance standards, and reduce shrinkage. Tamper-evident solutions support these goals without slowing down operations. When paired with strong procedures, they play a key role in preventing loss and keeping your operation secure from start to finish. If internal theft is a concern, now’s the time to upgrade!

Secure Your Workflow with Shosky Security’s Tamper-Evident Seal & Tape Solutions

Need to secure your production line or warehouse workflow? Shosky Security offers a wide range of tamper-evident seals, tapes, and labels designed for real manufacturing challenges. Contact us for custom tamper-evident solutions or request a free product sample.