With global e-commerce orders passing the 4.5 billion mark monthly, product protection in transit is more critical than ever. And tamper-evident packaging is one of the most effective ways to prove your product’s integrity from warehouse to doorstep.

However, not all tamper-evident solutions provide the same level of protection or value. Some materials offer basic visual cues, while others use advanced technology. The cost difference can be huge. This guide explores the materials that make modern packaging more secure.

Why Material Choice Matters in Tamper-Evident Packaging

The material used in tamper-evident packaging directly impacts its strength and effectiveness. High tensile strength materials (over 5,000 psi) offer significantly better resistance to tampering compared to other options, enhancing overall protection. This added strength helps prevent unauthorized access.

Durability is also key. About 23% of tamper-evident issues arise from material breakdown during transport, which can compromise packaging integrity. By choosing strong, stable materials, brands can ensure the protection remains intact from factory to shelf.

Material properties also affect how tampering is spotted. Clear polymers allow visual checks, and 68% of buyers look for visible seals. Also, in pharmaceuticals, advanced materials with barrier features help cut product damage by 82%. So, it’s not just about tamper signs—it’s also about safety and product quality.

Common Materials Used in Tamper-Evident Packaging

Tamper-evident packaging relies on specialized materials that provide clear signs of tampering. Each material has distinct properties that contribute to security, durability, and functionality. Here are the most commonly used materials in tamper-evident solutions:

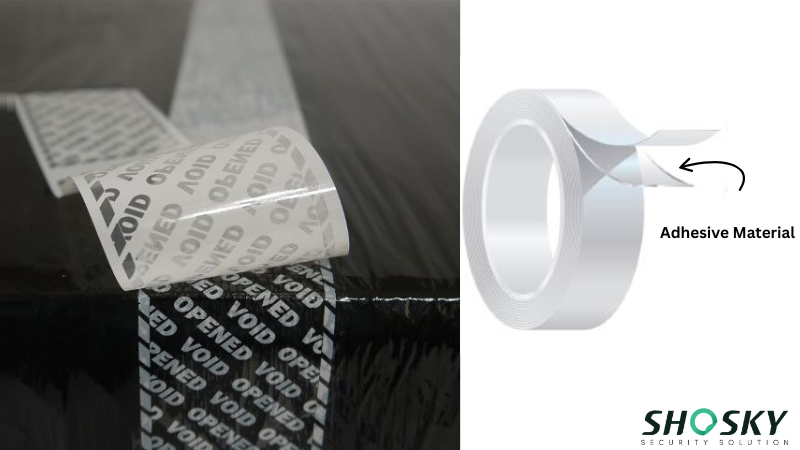

1. Adhesive-Based Materials

Adhesives are a critical layer of defense in tamper evident packaging like security tapes, security labels, and security seals. Once applied, they make resealing either impossible or highly visible. They play a vital role in maintaining product safety, especially in items like essential oil containers, electronics, and pharmaceuticals that require protection from interference.

- Key properties: Shows clear signs of tampering (e.g., “VOID” messages, color shifts, or residue)

- Types: Permanent adhesives, void-pattern adhesives, and frangible adhesives

- Material composition: Acrylic, rubber, polyester, polypropylene, and ultra-low tack adhesives

- Best uses: Used on tamper-evident containers, small sleeves, and as labels across multiple colors

There are different types of adhesive-based materials, each with its own reaction when tampered with. Some tear, others leave behind messages, while a few crumble entirely. Their strength lies not only in their bond but in how they make any attempt at tampering immediately obvious to the consumer.

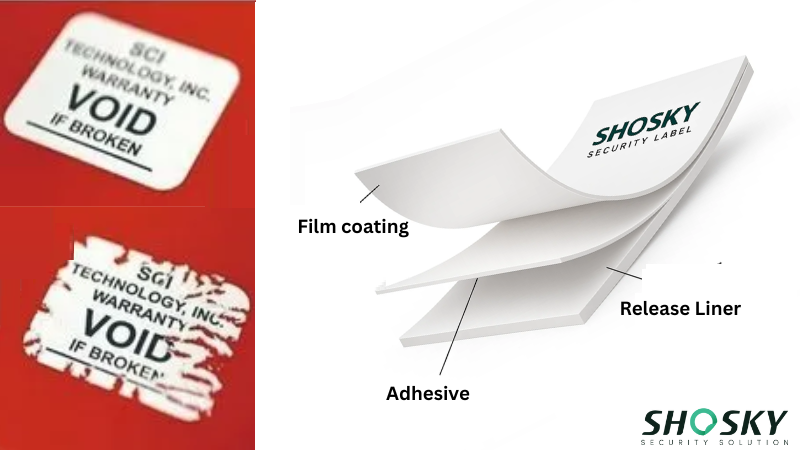

2. Tamper-Responsive Films and Laminates

Tamper-responsive films are used when secure packaging needs a clear, physical reaction to tampering. These materials are popular in tamper-evident containers, security seals, and overwrapping for industries like food, cosmetics, and pharmaceuticals.

- Key properties: Respond by tearing, breaking, or distorting if someone tries to open or remove them

- Types: Destructible vinyl films, polyester (PET) films, and holographic films

- Material composition: Includes PVC, PET, and multi-layered polycarbonate films

- Best uses: Used on items that require protection and tamper visibility in multiple colors

These films are designed to be both strong and sensitive. They are resistant to scratches, moisture, and light handling. And their strength protects the product, while their tamper response helps expose any interference. Many are applied as shrink bands or wraps that change shape or break apart when handled improperly.

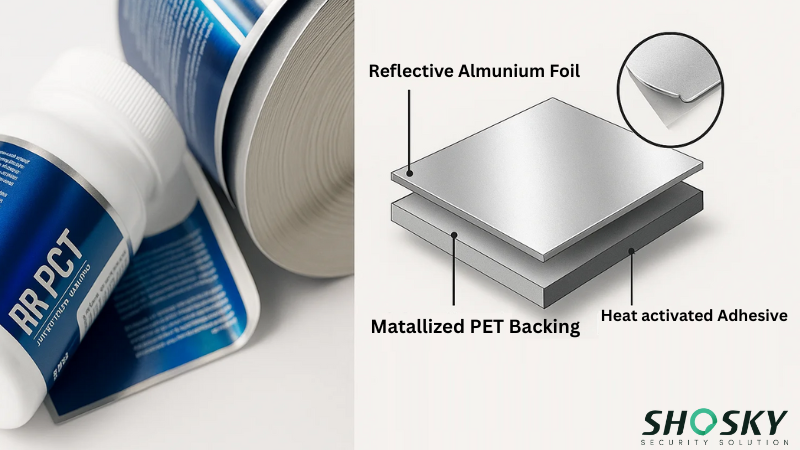

3. Metal-Based Tamper-Evident Materials

Metal-based materials are used when product packaging requires high durability and a strong barrier against tampering. They’re common in secure packaging seals for pharmaceuticals, essential oil containers, and food products that need to stay airtight and protected. When tampered with, these materials show clear signs through punctures, creases, or separation.

- Key properties: Reflective surface, high barrier protection, tear-resistant

- Types: Aluminum foils with security printing, and metallized polyester films

- Material composition: Thin-gauge aluminum or PET with aluminum coating

- Best uses: Used in secure packaging for products that require protection and long shelf life

Aluminum foils and metallized films not only block light, oxygen, and moisture but also deliver strong visual feedback when damaged. They’re especially helpful for many types of products where product safety and shelf life are critical. These materials also work well with heat-sealed tamper-evident seals and over wrapping machines.

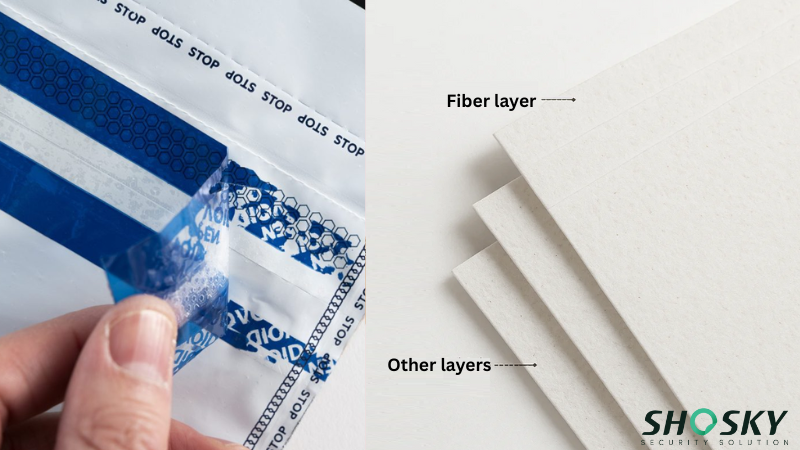

4. Paper-Based and Fiber Materials

Paper and fiber-based tamper-evident materials are gaining attention for being both secure and eco-conscious. They’re especially useful in packaging that needs to be user friendly, easy to apply, and recyclable. While not as tough as metal or plastic, these materials show clear signs when tampered with—like tearing or fiber disruption.

- Key properties: Recyclable and biodegradable, good for eco-conscious packaging

- Types: Tear-evident kraft paper and fiber-based tamper proof tape

- Material composition: Reinforced paper with added fragility or fiberglass threads

- Best uses: Security envelopes, small sleeves, tamper-evident tape on boxes

They’re commonly used in tamper-evident packaging for e-commerce, official mail, and document packaging. Brands can print visual components, warnings, or patterns on these tapes to reinforce product safety and authenticity. While not ideal for all types of secure packaging, these materials are a strong fit for lightweight product packaging where fast application matters.

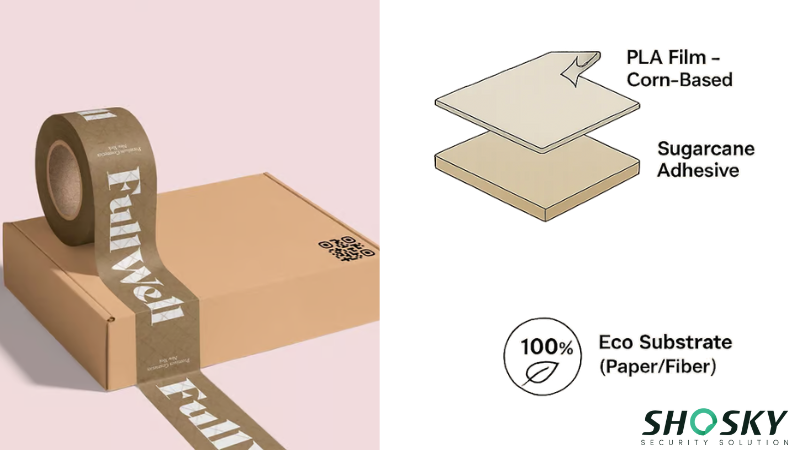

5. Biodegradable and Sustainable Tamper-Evident Materials

PLA (polylactic acid) films and sugarcane-based adhesives are leading choices in this category. PLA is made from corn starch and works well for short-term tamper evident containers and shrink bands. Sugarcane adhesives bond securely to paper and fiber surfaces, offering a green alternative to synthetic glue systems.

- Key properties: Renewable, non-toxic, supports clear tamper-evidence

- Types: PLA security films, and sugarcane adhesives

- Colors & Customization: Available in multiple colors for branding

- Common uses: Essential oil containers, small sleeves, user friendly eco-packs

These materials are best for brands that want visible tamper-evidence while meeting sustainability and environmental goals. Though less durable than PET or metal films, they offer a solid option for products that require protection without the waste.

Comparing Tamper-Evident Materials: Strength, Cost & Applications

When selecting tamper-evident materials, businesses must consider not only the security they provide but also their cost, durability, and suitability for specific applications. Below is a breakdown of some common tamper-evident materials, focusing on their strength, cost-effectiveness, and most appropriate applications.

Adhesive-Based Materials

Adhesive solutions offer versatile protection across multiple industries, with studies showing they’re used in over 60% of tamper-evident applications. Their effectiveness in ensuring product safety has made them essential for pharmaceutical and food packaging.

| Type | Strength | Cost | Applications |

|---|---|---|---|

| Void-Pattern Adhesives | High bond strength; leaves “VOID” pattern on tampering | Mid-range | Electronics, luxury goods, pharmaceuticals, tamper evident containers, secure packaging |

| Frangible Adhesives | Medium to high; breaks easily when tampered with | Mid-range | Warranty seals, documents, essential oil containers, tamper evident tape |

| Permanent Adhesives | Extremely high; very difficult to remove without damage | Low | General packaging, security labels, over wrapping, product packaging |

These adhesive solutions provide a clear visual indication when tampering occurs, helping consumers identify compromised products while building brand trust and loyalty.

2. Destructible Films and Laminates

Films and laminates represent the fastest-growing segment in tamper-evident packaging, with market research showing 34% annual growth in consumer goods applications. Their ability to provide visible evidence of broken seals makes them particularly effective for bottles and containers.

| Type | Strength | Cost | Applications |

|---|---|---|---|

| Destructible Vinyl Films | High; shatters on removal, making tampering irreversible | High | Pharmaceuticals, high-end goods, shrink bands, visual components |

| Polyester (PET) Films | High; tear-resistant, holds up to stress | Mid-to-high | Electronics, health products, food packaging, induction seals |

| Holographic Laminates | Very strong; difficult to copy, shows clear signs of tampering | High | Luxury goods, brand protection, authentication labels, tamper evident tape |

The visual security these materials provide allows customers to quickly identify tampering attempts, making them ideal for protecting high-value products and building consumer confidence.

3. Metal-Based Materials

Metal-based solutions provide superior protection against tampering while also creating effective barriers against contamination. Their strength and durability make them ideal for pharmaceutical and food applications where safety is paramount.

| Type | Strength | Cost | Applications |

|---|---|---|---|

| Aluminum Foil | Extremely strong; shows tampering through punctures | High | Pharma blister packs, food and beverage containers, electronics |

| Metallized Polyester Films | Very strong; puncture-resistant, often combined with other security features | Mid-to-high | Secure food packaging, luxury items, essential oil containers, product packaging |

Studies show that consumers instantly recognize foil seals as security features, making metal-based materials particularly effective for communicating safety to customers. The study concluded that metallic treatments add a premium feel to the products, suggesting higher quality and, by extension, enhanced security.

4. Paper-Based Materials

Paper-based tamper-evident solutions offer environmental benefits without compromising security. These commonly used materials appeal to eco-conscious brands seeking to protect products while reducing plastic usage.

| Type | Strength | Cost | Applications |

|---|---|---|---|

| Kraft Paper | Moderate; tears easily to show tampering | Low | E-commerce packaging, documents, shipping labels, tamper evident containers |

| Fiber-Based Tamper Tape | Medium; embedded fibers tear clearly on tampering | Low-to-mid | Retail seals, envelope security, small sleeves, documents requiring protection |

Stats show that these materials can reduce packaging costs by up to 40% while still providing clear evidence when seals are broken or packaging is compromised.

5. Biodegradable and Sustainable Materials

The newest generation of tamper-evident materials addresses both security and sustainability concerns. These innovative solutions help companies protect products while meeting increasingly important environmental goals.

| Type | Strength | Cost | Applications |

|---|---|---|---|

| PLA (Polylactic Acid) Films | Moderate; compostable, shows tampering through tearing | Mid-range | Food packaging, short-term product seals, eco-conscious branding, secure but user friendly options |

| Sugarcane-Based Adhesives | Medium; good bond for most paper/fiber applications | Mid-range | Organic products, sustainable packaging, security seals for biodegradable packaging |

With consumer studies showing that 73% of customers prefer environmentally responsible packaging, these materials help brands balance product safety with sustainability commitments.

Industry-Specific Tamper-Evident Materials

Different industries face unique challenges when it comes to packaging security. Below is a breakdown of how various industries apply tamper-evident solutions to improve security, maintain product integrity, and align with regulatory standards.

Pharmaceutical and Medical Industries

The pharmaceutical sector employs the most stringent tamper-evident materials due to critical safety concerns, with FDA regulations requiring visible evidence of tampering since the 1982 Tylenol crisis. Studies show tamper-evident packaging in this industry has reduced medication tampering incidents by 92% over the past two decades, directly improving patient safety and brand protection.

The common materials include: Void-pattern adhesives for pharmaceutical containers, frangible films that become broken when lids are removed, blister packs with aluminum foil backing that show puncture evidence, destructible holographic seals for boxes, and PLA-based biodegradable films for eco-conscious brands.

Food and Beverage Industry

Food and beverage companies utilize tamper-evident materials that balance product protection with consumer convenience, with industry data showing 87% of consumers specifically check for intact seals on these products. The beverage sector leads implementation, with tamper-evident bands and shrink sleeves securing over 6 billion bottles annually in North America alone.

The common materials include: Metallized polyester films for premium food packaging, PVC and PETG shrink sleeves that conform tightly to beverage bottles, kraft paper seals for artisanal products, induction-sealed foil liners for jars, and tamper-evident pouches with specialized adhesives that reveal evidence of opening attempts.

Cosmetics and Beauty Industry

The cosmetics industry faces unique challenges in balancing security with premium aesthetics, leading to sophisticated tamper-evident materials that protect while enhancing brand perception. Market analysis indicates that 76% of beauty brands now incorporate some form of tamper-evident packaging, with high-end products showing the greatest adoption rates.

The common materials include: Holographic destructible films that protect premium bottles, printed cellophane overwraps that show evident signs when broken, frangible adhesive tapes securing lids on jars, color-changing security seals that react to tampering attempts, and plant-based adhesives for eco-conscious cosmetic brands.

Luxury Goods and High-End Retail

Luxury brands use tamper-evident materials not only for security but as an extension of brand identity, with custom security features incorporated into 82% of high-end packaging. These sophisticated materials protect against counterfeiting while reinforcing the premium product experience consumers expect when purchasing luxury items.

The common materials include: Custom-designed security foils with brand-specific tamper-evident features, metallized polyester films with proprietary patterns that reveal tampering, holographic security labels with serialization for individual product authentication, and specialty adhesives engineered to leave clear evidence on luxury boxes when access is attempted.

Electronics and High-Tech Devices

Tech companies implement multi-layered tamper-evident materials to protect high-value products throughout the distribution chain, with 91% of manufacturers reporting tampering attempts have decreased since implementing advanced security packaging. These specialized materials protect not only against theft but also unauthorized access that could compromise device security.

The common materials include: Polyethylene security films that show clear breaking patterns when removed, void-pattern adhesive security seals for access points on containers, tear-resistant vinyl labels with serialization for product authentication, specialized tape systems that change appearance when removed from packaging, and tamper-evident pouches for accessories and smaller components.

Key Considerations When Selecting Tamper-Evident Packaging Materials

Choosing the right tamper-evident packaging material depends on more than just preventing tampering. Product type, risk level, cost, and sustainability goals all play a role. Here’s a quick breakdown of key points to consider:

- Product type & regulations: Sectors like pharma and food have strict standards for packaging materials.

- Security level: High-risk items need stronger solutions like destructible films or permanent adhesives.

- Cost-effectiveness: Premium options offer better protection but come at a higher cost.

- Sustainability goals: Biodegradable films and recyclable adhesives support eco-friendly packaging.

Balancing these factors helps businesses choose materials that match both their security needs and their brand values. It’s not just about preventing tampering—it’s also about meeting industry regulations, staying within budget, and aligning with consumer expectations.

FAQs

What are the most secure tamper-evident packaging materials?

Destructible films, holographic laminates, and permanent adhesives offer the highest security.

Which industries require tamper-evident packaging the most?

Pharmaceuticals, food and beverage, and electronics industries need tamper-evident packaging the most.

Where can businesses source tamper-evident materials in bulk?

Businesses can find bulk tamper-evident materials from specialized packaging suppliers and manufacturers. Many offer custom solutions for large orders.

Conclusion

The packaging you choose speaks volumes. It shows how much you care about product safety, customer trust, and even your environmental impact. Tamper-evident materials offer a way to protect goods and prove integrity at every step of the journey. But not all materials work the same. By understanding the options—from cost to strength—you can build better packaging that meets your product’s needs and your brand’s values.

Protect Your Products with Shosky Security’s Tamper-Evident Packaging Materials

When security matters, choose Shosky Security for all your tamper-evident packaging needs. With years of experience and a wide selection of customizable products, we offer the ultimate protection against tampering and counterfeiting. Get in touch today to discuss your needs!