When a shipment leaves your facility, how confident are you that it will arrive untampered? For companies transporting high-value shipments, the type of security seal used can make all the difference. The right tamper-evident solution balances security with ease of use, cost, and compliance.

Currently, container seal labels and pull-tight seals represent the frontline defense against supply chain breaches. However, choosing between them requires an understanding of their fundamental differences. In this article, we’ll break down how they compare in terms of strength, usability, and long-term value.

What is a Container Seal Label?

Container seal labels are adhesive-based security devices designed to provide visual evidence of tampering. These specialized security labels attach to container openings, packaging seams, or access points, creating a tamper-evident barrier.

When removal is attempted, these labels tear, display hidden warning messages, or leave residue behind. This visual evidence immediately alerts recipients that someone may have compromised the package contents.

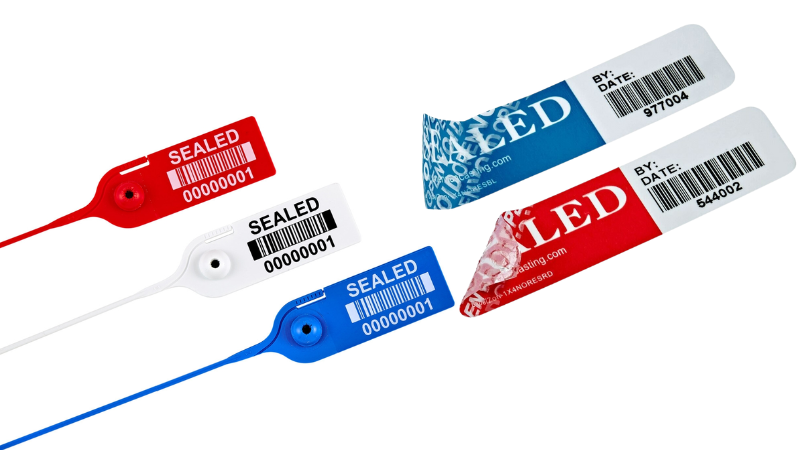

Key features of container seal labels include:

- Tamper-evident design that shows “VOID” or “OPENED” messages when peeled

- Serialized tracking numbers for inventory management

- Customizable with company logos and contact information

- Available in various sizes, colors, and adhesive strengths

- Destructible materials that prevent intact removal

- Weather-resistant options for outdoor shipping conditions

Container seal labels work best for packages, boxes, envelopes, and smaller shipping containers where visual verification is sufficient, and a strong physical barrier isn’t required.

What is a Pull-Tight Seal?

Pull-tight seals are physical security devices consisting of a plastic or metal strap with a locking mechanism. These security seals thread through container hasps, door handles, or other closure points and lock into place, creating a mechanical barrier.

The design prevents removal without cutting the strap or breaking the locking mechanism. This provides clear evidence of tampering that’s immediately visible upon inspection. Unlike labels, pull-tight seals offer a physical deterrent along with tamper evidence.

Key features of pull-tight seals include:

- High-strength plastic or metal construction resistant to tampering

- Unique serial numbers for tracking and verification

- Single-use design that requires destruction for removal

- Available in various tensile strengths for different security needs

- Color-coding options for quick visual identification

- Different locking mechanisms based on security requirements

- Weather and chemical resistance for harsh environments

Pull-tight seals are ideal for shipping containers, truck doors, rail cars, and other large shipments requiring higher security levels than adhesive labels can provide.

Container Seal Labels vs. Pull-Tight Seals: A Detailed Comparison

When choosing between container seal labels and pull-tight seals, it’s important to look at how each performs in real-world security scenarios. Both offer tamper evidence, but they function differently based on application and packaging type. In this section, we’ll compare their security performance to help you decide which offers better protection for your goods.

Security Effectiveness

Container seal labels offer basic visual security through tamper-evident adhesives. When removed, they display “VOID” patterns or tear irregularly. This provides clear evidence of tampering but minimal physical protection against determined intruders.

Pull-tight seals deliver superior physical security with their mechanical locking mechanisms. These devices require cutting tools for removal, creating a stronger deterrent against theft. For ships carrying valuable cargo, pull-tight seals provide enhanced protection against piracy concerns.

Security codes and serial numbers on both types help verify authenticity, but pull-tight seals generally offer higher-grade security for maritime shipping requirements. Many shipping companies prefer pull-tight seals when transporting high-value goods where security protocols are stricter.

Ease of Use

Container seal labels apply quickly with peel-and-stick simplicity. Staff can secure multiple packages rapidly without special training or tools. This efficiency reduces labor costs during the packing process.

Pull-tight seals require threading through closure points and pulling tight until locked. This takes slightly longer and demands more precision. However, crew members can still apply these seals without extensive training.

For large shipping operations handling numerous containers daily, the time difference adds up. Container seal labels support faster processing when quick turnaround is essential.

Durability

Pull-tight seals excel in harsh environments. Made from weather-resistant plastics or metals, they withstand temperature fluctuations, saltwater exposure, and rough handling common in sea transport. These security seals remain functional throughout extended shipping journeys.

Container seal labels may degrade in extreme conditions. Humidity and temperature variations can compromise adhesive strength over time. Some premium labels offer enhanced durability, but they rarely match pull-tight seals for long-term performance.

For international shipping crossing multiple climate zones, pull-tight seals provide more reliable protection. Their physical construction ensures tamper evidence remains intact despite the challenging conditions ships encounter.

Cost Comparison

Container seal labels typically cost less per unit. Their simple design and materials keep production expenses low. For high-volume shipments or items with lower value, labels provide cost-effective security.

Pull-tight seals require more materials and complex manufacturing, driving higher unit prices. However, when considering potential losses from theft or tampering, this added expense often represents worthwhile insurance for valuable cargo.

The total cost calculation should include implementation time, storage requirements, and disposal processes. While pull-tight seals have higher upfront costs, they may deliver better long-term value by preventing costly security incidents.

Customization Options

Both seal types offer customization, but with different capabilities. Container seal labels accept vibrant colors, detailed logos, barcodes, and sequential serial numbers. Their flat surface allows for extensive printed information, supporting comprehensive tracking systems.

Pull-tight seals permit color coding, embossed or laser-etched identification numbers, and basic branding. Their three-dimensional form limits the printing area compared to labels.

For comprehensive security programs requiring detailed documentation, container seal labels provide more information space. However, pull-tight seals can integrate with electronic tracking systems through RFID chips, enhancing their functionality in modern supply chain management.

Application Requirements

Container seal labels work best on clean, smooth surfaces. They require proper application technique to ensure adhesive bonding. Environmental factors like dust or moisture can interfere with proper attachment.

Pull-tight seals need specific structural elements—hasps, handles, or specially designed locking points—to secure properly. Most shipping containers and vessel access points accommodate these devices by design.

The physical characteristics of what you’re protecting should determine your choice. Small packages and document envelopes suit labels, while shipping containers and truck doors demand pull-tight seals.

Best Use Cases for Container Seal Labels

Container seal labels provide effective security solutions for specific shipping scenarios. Below is a breakdown of their optimal applications:

| Industry | Application | Key Benefits |

|---|---|---|

| Pharmaceutical | Medicine packages | Sequential numbering for inventory tracking; Tamper-evidence for safety |

| E-commerce | Consumer parcels | Cost-effective for high volume shipping; Clear evidence of tampering |

| Financial | Document mailers | Protection for sensitive information; Easy verification by recipients |

| Laboratory | Sample containers | Maintains integrity without adding bulk; Meets chain of custody requirements |

| Food & Beverage | Product packaging | Helps meet safety requirements; Builds consumer confidence |

| Electronics | Retail packaging | Security without damaging products; Supports warranty verification |

| Logistics | Box closures | Quick application for fast processing; Visual check during transit |

| Medical | Test kit sealing | Ensures sterility until use; Documents first opening |

These security labels work best where visual security indicators are sufficient and processing speed matters for operational efficiency.

Best Use Cases for Pull-Tight Seals

Pull-tight seals deliver robust physical security for more demanding shipping scenarios. The table below highlights their most effective applications:

| Industry | Application | Key Benefits |

|---|---|---|

| Maritime | Shipping containers | Withstands sea conditions; Protects against piracy concerns |

| Transportation | Truck door sealing | Physical barrier against theft; Visible deterrent during transit |

| Chemical | Hazardous material transport | Meets safety protocols; Prevents unauthorized access |

| Military | Equipment shipping | Supports security requirements; Provides numbered tracking |

| Banking | Cash-in-transit bags | Sequential numbers for verification; Clear evidence if cut |

| Customs | Border crossing cargo | International shipping compliance; Easy inspection by officials |

| Energy | Meter sealing | Protection against tampering; Weather-resistant durability |

| Aviation | Cargo holds security | Supports airport security protocols, Quick visual verification |

| Legal | Evidence storage | Chain of custody documentation; Court-admissible security |

| Waste Management | Hazardous disposal | Environmental compliance; Prevents unauthorized dumping |

These seals provide superior protection for high-value cargo and situations where security requirements demand physical barriers against tampering.

Key Considerations When Choosing the Right Seal for Your Business

Selecting the right seal for your business requires more than a one-size-fits-all approach. It begins with evaluating the unique risks involved in your operations, from the value of your goods to potential tampering threats along the supply chain. Here are the key factors to consider when choosing the right seal:

Risk Assessment

Evaluate your specific security risks first. Consider the value of your cargo and potential threats. Different regions present varying levels of piracy risk. High-threat sea routes may require stronger protection measures. So, assess if your goods might be targets for terrorism or organized theft. Higher-risk shipments need enhanced security protocols.

Regulatory Requirements

Many industries must meet established security codes. Research requirements before selecting seal types. International shipping crosses multiple regulatory jurisdictions. Each flag state may have unique security requirements. The International Ship and Port Facility Security Code sets minimum standards. Your seals must meet these global protocols.

Supply Chain Integration

Your seals should integrate with existing tracking systems. Compatible serial number formats ensure seamless documentation. Consider how seal verification fits your receiving procedures. Simple verification processes reduce processing delays. However, evaluate how seal data enters your inventory management system. Automated scanning can reduce human error.

Cost-Benefit Analysis

When comparing container seal labels and pull-tight seals, it’s important to look beyond just the upfront price. While seal labels may seem more budget-friendly at first, they offer basic security and may require more frequent replacements. On the other hand, pull-tight seals have a higher unit cost but provide stronger protection and are more durable over time.

| Factor | Container Seal Labels | Pull-Tight Seals |

|---|---|---|

| Unit Cost | Lower initial investment | Higher per-unit cost |

| Application Time | Quick, minimal training | Moderate, some training needed |

| Security Level | Basic visual evidence | Strong physical barrier |

| Damage Prevention | Minimal theft deterrent | Significant deterrent effect |

| Replacement Rate | May need more frequent replacement | Longer service life |

| Response Options | Limited evidence if breach | Clear evidence for insurance claims |

Calculate total costs, including potential loss from security incidents. Prevention often costs less than dealing with the aftermath of theft.

Implementation Planning

Develop clear protocols for seal application and verification. Documented procedures prevent security gaps. Create a response plan for when seal tampering is detected. Quick action can minimize damage from security breaches. Establish an umbrella security strategy where seals form just one component.

Layered security provides better protection. Set a regular review date to assess seal effectiveness. Security needs change as world shipping risks evolve. Keep security measures updated based on incident reports. Learning from past breaches improves future protection. Request assistance from trusted seal manufacturers for implementation. Their expertise can help optimize your security program.

Questions to Ask Before Deciding

- What’s the typical value of our shipments?

- How sophisticated are potential threats to our cargo?

- Do we need physical barriers or just tamper evidence?

- What tracking capabilities must our seals support?

- How will seal verification integrate with existing processes?

- What’s our budget for seal implementation and maintenance?

- How will weather and handling conditions affect seal performance?

- What department will manage the seal inventory and security protocols?

- How will we board and secure vessels or vehicles consistently?

- What training will staff need for proper seal use?

Answering these questions will result in a more effective security solution tailored to your specific business needs.

FAQs

Can pull-tight seals be customized with serial numbers?

Yes, pull-tight seals can include a serial number. However, they offer fewer customization options than container seal labels.

Are container seal labels tamper-evident?

Yes, container seal labels are designed to be tamper-evident and will show visible signs if altered or removed.

How long do pull-tight seals last compared to container seal labels?

Pull-tight seals are durable for short-term use, whereas container seal labels provide longer-lasting protection, especially in tough conditions.

Conclusion

In summary, container seal labels and pull-tight seals both offer strong shipping security. Container seal labels are ideal for long-term, high-value cargo with added customization. Pull-tight seals work well for quick, cost-effective sealing of bulk shipments. Evaluate your needs to determine which option best fits your security and operational requirements!

Enhance Your Shipping Security with Shosky Security’s Solutions

Whether you need a container seal label or a pull-tight seal, Shosky Security offers high-quality, tamper-evident maritime security solutions. Our seals are designed to meet strict safety and compliance standards. Reach out and secure your supply chain.