Customized Printed Sequential Number Tamper Proof Tape

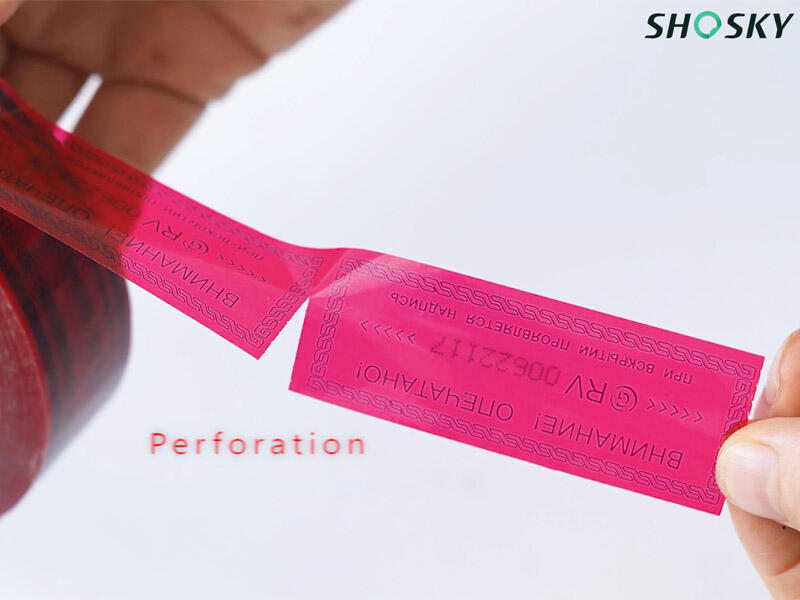

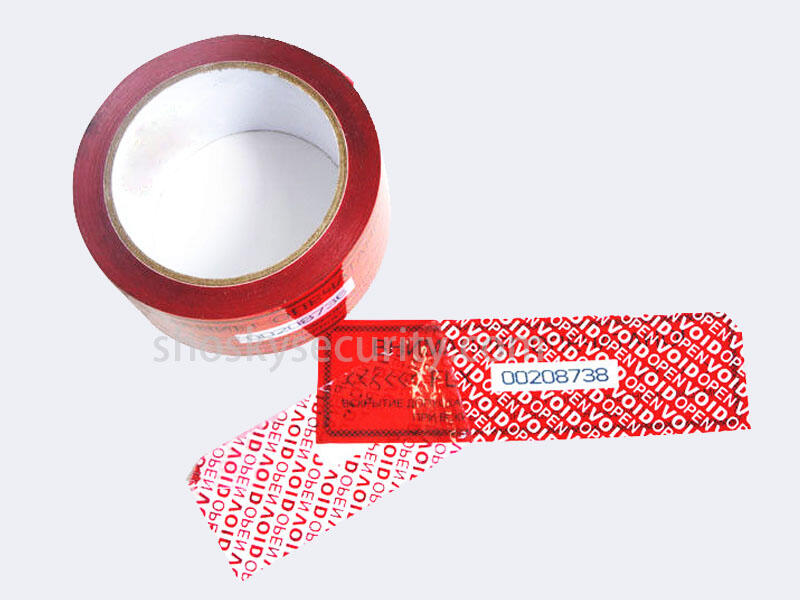

This is customized numbered security tape with perforation every 150mm. All personalized printing and numbering is under the surface making it is not possible to delete or alter.

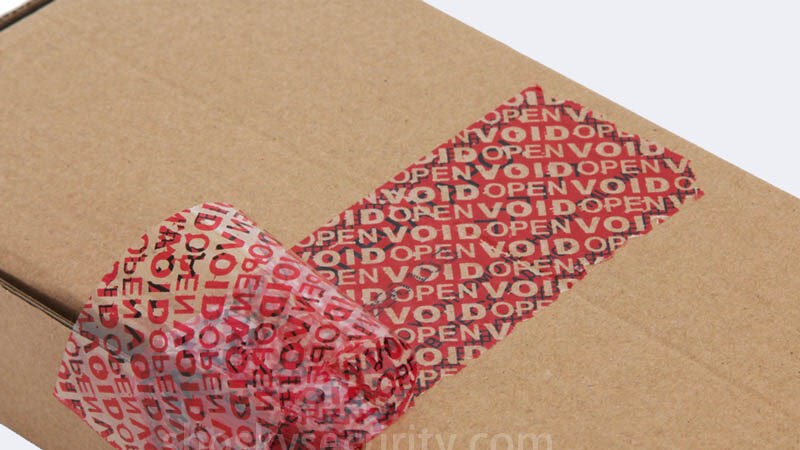

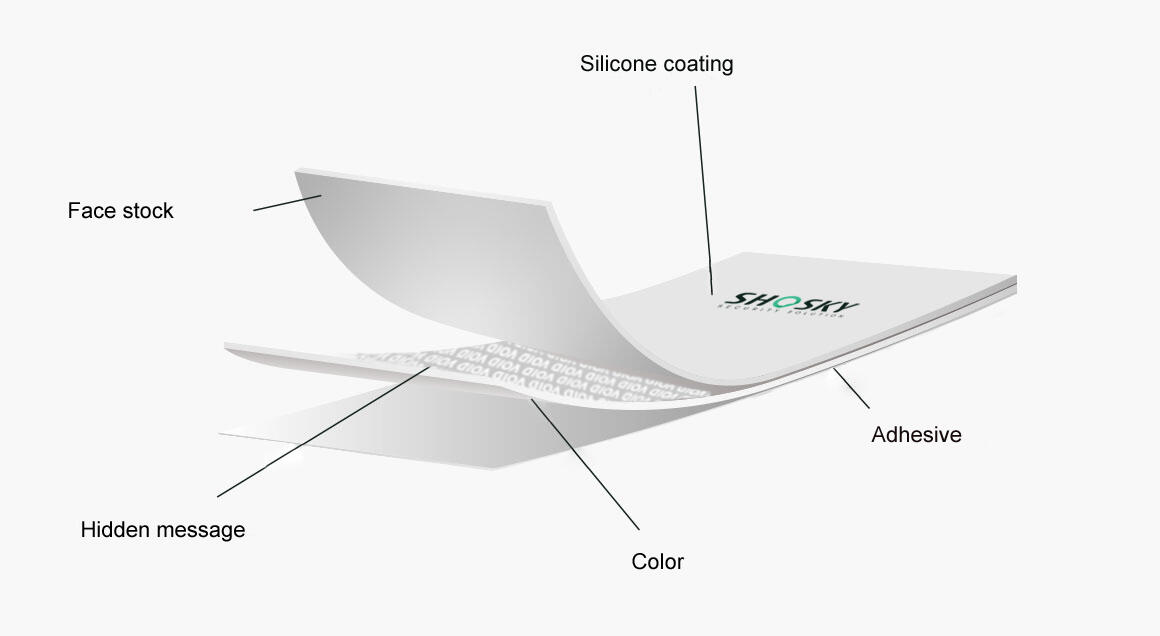

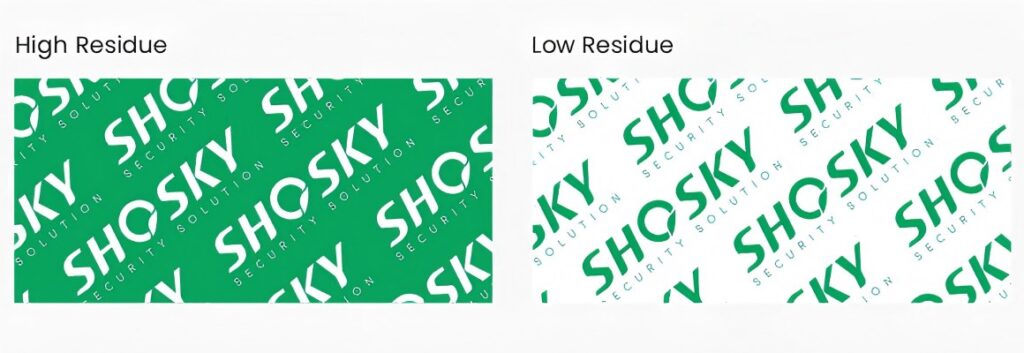

All the designed information is fully transferred to the application surface and exposes the obvious void message when tape tampered with, as the surface of the tape is siliconized, once it has been peeled away, it is impossible to re-seal with scotch tape.

There are a wide range of options for custom security tape for our customer as bellow:

- Tape width and length can be customized, our standard width is 50mm, any other width is available, length could be 50m, 100m, 500 meters and more

- Film thickness, colour, void message and surface printing customization is available

- Perforation and sequential numbering usually is 150mm, any other perforation distance can be customized

- No way to re-use