Whether you are a supplier, retailer, or perhaps just planning to move out, a carton sealing tape is one of the essentials you must have. Packing and shipping goods are not easy, but if you want to get it done effectively, you have to consider the sealing tape you will be using. Here is a comprehensive guide about carton sealing tape that will definitely help you a lot.

What is Carton Sealing Tape

Carton sealing tapes are typically used for packing and sealing boxes. They come in a wide variety of lengths, widths, thicknesses, and colors, and also with various adhesive systems. Since carton sealing tapes are used in different environments, they can be used for corrugated cardboard boxes. With the help of getting the ideal carton sealing tape, the box used can now maintain the integrity of the package and hold its contents safely.

Essentially, the adhesive solution, carrier strength, and other physical properties of carton sealing tapes used for sealing boxes must perform the required task. What is more, you should know several grades and varieties of carton sealing tape. This is essential because not all cartons require the same carton sealing tape. In fact, some boxes, like recycled corrugated boxes, may need a different carton sealing tape than cardboard that is not recycled.

Knowing Common Packing Terms

It is crucial for businesses that rely on packing tapes to select the ideal carton sealing tape to seal their cartons and boxes. Keep in mind that the wrong choice of tape can cost enterprises money and time and even disrupt efficiency. This is why standard terms are used to help describe your preferred carton sealing tapes. Check out the list below.

- Tensile Strength

This measures the force needed to pull something to the point where it tears and breaks.

- Carrier or Backing Material

This is the component of a tape the adhesive is applied to. The most commonly used tape backing materials are cloth, paper, vinyl, and polypropylene.

- Elongation

This is connected to the tensile strength, for it is about how far a tape can stretch prior to breaking. Elongation is usually measured by percentage, whereas tensile strength is measured in pounds.

- Core Size

The core size is also essential because it is the inside roll diameter of a carton sealing tape.

- Length

Providing the correct length measurement of the tape on the roll is also crucial. Carton sealing tapes are commonly 55-yard or 110-yard rolls. On the other hand, machine length rolls can vary between 1000-2000 yards.

- Width

The width of the tape on the roll is another thing, and it is generally measured in inches or millimeters. For carton sealing tapes, the width could be 2 or 3 inches.

- Thickness

This is about how thick you want your carton sealing tape to be. For instance, economy carton sealing tapes could be less than 1.5 mils thick, whereas heavy-duty carton sealing tapes are more than 3 mils thick.

Common Types of Carton Sealing Tape

Generally, two types of carton sealing tapes are commonly used: pressure-sensitive and water-activated carton sealing tapes. Let us discuss them further.

Pressure Sensitive Carton Sealing Tape

Pressure-sensitive packaging tapes are the most popular option for carton sealing. These tapes have a pressure-sensitive adhesive coated onto a strong carrier or backing material, usually a plastic film. The tape comes off the roll already sticky and adheres to a surface when pressure is applied.

Pressure-sensitive adhesive (PSA) carton sealing tapes can be either machine or hand-applied. Hand tapes are used with a tape dispenser or packing tape gun. On the other hand, machine tapes are used with a tape machine that pulls the carton box through on a belt and seals the top and bottom simultaneously.

Although packaging tapes can be used for a broad range of applications, their adhesives are augmented for adhering to liner boards or corrugate cartons. The carrier or backing materials are also structured to offer the tensile strength required for carton sealing. However, not all packaging tapes are the same, meaning different cartons will require various carton sealing tapes. There are three kinds of PSA carton sealing tape consumers should be familiar with, each with its advantages and disadvantages.

- Hot-melt Carton Sealing Tape

Hot-melt packaging tape is the most economical and well-known selection when it comes to carton sealing. Hot-melt carton sealing tapes use synthetic rubber adhesives that provide great adhesion in application temperatures ranging from 40°F to 120°F.

Hot-melt carton sealing tapes are usually found in clear, tan, or white in color and are available for both hand and machine application in a range of 1.35 mil – 3 mil of thicknesses, whether they will be used for light, medium, or even heavy-duty applications. This durable carton sealing tape offers an impressive bond factor, is easy to unroll, and functions exceptionally under strain and stress. However, hot-melt adhesive tapes tend to be yellowish over time.

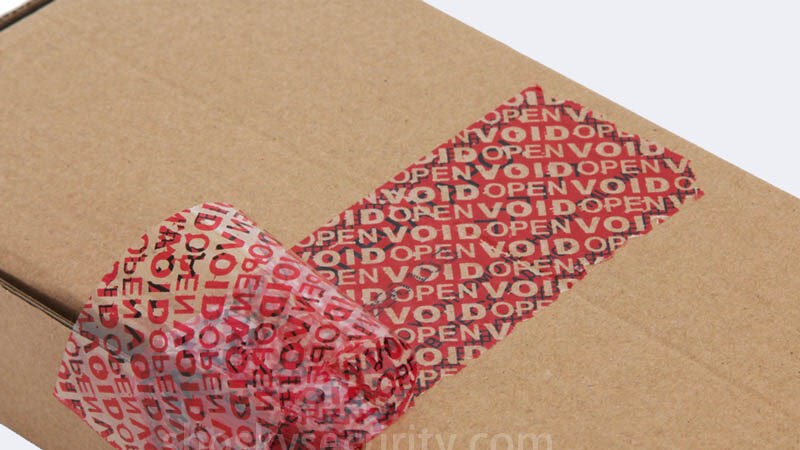

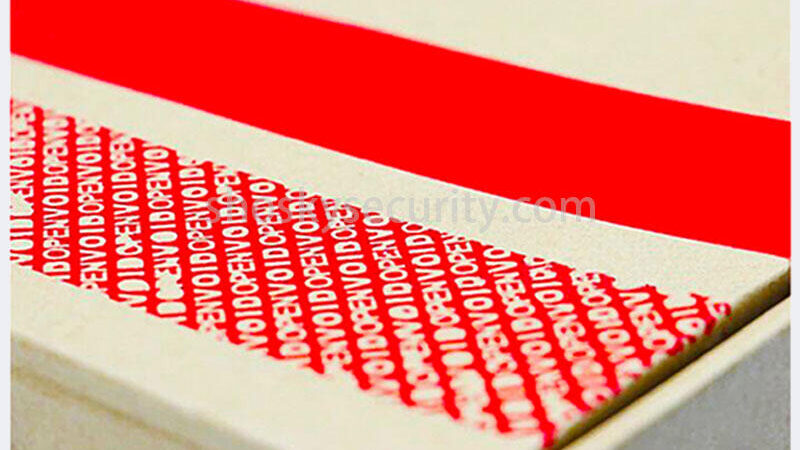

- Tamper Evident Packaging Tapes

Once broken or removed, tamper-evident packaging (TEP) adhesive tapes present visible evidence that tampering has occurred. These security tapes are usually used in the food and beverage, pharmaceutical, and electronics sectors and for high-value consumer goods as an anti-pilferage measure.

So, if you are into a business that involves selling products and shipping, tamper-evident packaging tapes could be a perfect selection for your carton sealing tapes. Shosky can help you with that. Our company even offers custom-printed packing tapes that can help your branding and products as well.

- Acrylic Carton Sealing Tape

Acrylic carton sealing tape almost looks similar to hot melt, but the former offers different functionality features. Acrylic adhesive tapes maintain good adhesion across a vast temperature range, which is about from 32°F to 140°F, making them ideal for applications that involve refrigerated products or carton boxes that will be stored or shipped in extreme heat or cold temperatures.

Moreover, they resist yellowing in the long run and provide top-notch clarity. This is why acrylic tapes are an excellent selection for printed or white cartons since they will not obscure the carton design.

- Natural Rubber Carton Sealing Tape

Natural rubber packing tapes use natural rubber adhesives instead of synthetic ones. These PSA tapes are a bit more expensive. Still, they offer excellent adhesion across a wide range of temperatures and even in complex environments.

Interestingly, natural rubber tape adheres to almost anything and can be used in extreme temperatures or harsh environments that are very humid or have high levels of dust or aerosols in the air. These are the PSA carton sealing tapes to turn to when nothing else works for your application.

Water-activated Paper Carton Sealing Tape

Also coined as gummed paper tape, water-activated paper carton sealing tape is a tamper-proof or TEP tape made from fully sustainable, 100% sustainable materials that present no landfill issues. Water-activated paper carton sealing tape is an eco-friendly substitute to PSA plastic tape, which offers enhanced security and better presentation with cost savings.

Water-activated carton sealing tapes work differently compared to PSA tapes. These tapes have a gummed adhesive and a paper backing that is dry to the touch but gets sticky until water is applied. When wet, they form a solid bond to a corrugate or linerboard carton, and in turn, the tape becomes part of the carton box and cannot be removed. Recipients of packages that have water-activated paper tapes cut through the adhesive tape instead of peeling it off to open the parcel.

Water-activated paper tapes have become the go-to carton sealing tape selection for high-volume fulfillment warehouses. This kind of tape can be utilized for packages ranging up to 150 pounds, which is the upper weight limit for ground shipment by FedEx and UPS. Also, the water-activated paper adhesives are accessible in various grades for light, medium, or heavy-duty applications, plus you can select from either standard or reinforced rolls.

Reinforced rolls have a carrier or backing composed of two layers of paper with fiberglass filaments in between for additional substance. This is why this type of carton sealing tape is the ideal option for sealing and packing heavy-duty packages. What is more, to know, water-activated carton sealing tape is applied through a specialized tabletop tape dispenser that can be used either manually or electrically. Using this type of tape dispenser is fast, easy, and convenient.

How to Choose the Most Suitable Carton Packaging Tape

Selecting the right carton of packaging tape might seem like an important decision for your overall packaging system. But actually, it is not, for it is as essential to your secondary packaging strategy as placing some fillers in your box in order to keep your contents guarded and secured. You need to know that incorrect carton sealing tape selection could affect not only the whole packaging but also its contents.

Choosing the correct adhesive tape for your cartons can avoid theft and product damage and even salvage your relationship and reputation with customers. So, from hot-melt carton sealing tapes to wet-activated paper tapes and everything in between, there are several things you have to consider when deciding on the right carton sealing tape:

- Grade

Carton sealing tapes are accessible in different grade ranges, which means varying levels of film and adhesive thickness. These grades offer a range of varying holding power and tensile strength. So, when planning what grade type of tape to buy, make sure to consider the size of the carton, its content weight, as wells as the production and shipping surroundings. As any of these variables increase, so should the grade of carton sealing tape you select.

- Environment

When choosing a carton sealing tape, do not ever forget to consider the production and storage environments. Factors such as temperature and environmental conditions (dust and humidity) can impact the tape seal quality.

- Application Method

There are two ways to apply carton sealing tapes: either in a manual process through a hand-held tape dispenser or an automated process by using an automatic or electric case sealer. The manual process presents an easy unwind and good tack for initial grab to the corrugated surface of the carton and strong film backing to avoid breaking and stretching all crucial parts of the package.

On the flip side, automated processes focus on quick tape unwinding to lessen the tape breakage caused by stretching and tearing during application. Carton sealing tapes offering instant adhesion are also advantageous in environments that need immediate palletization of cartons.

- Substrate

Another thing to consider is what carton material you are planning to seal. Remember, there are several carton types available, including recycled, thick or double-wall, printed or waxed corrugated cartons. Each one brings its own advantages to the distribution network and its faults when it comes to tape performance.

- Quality

Finally, the last thing to pay attention to when selecting a carton sealing tape is its quality. Good quality sealing tapes have good adhesion to the corrugated surface, are quick to unwind, and provide the durability required to withstand the distribution network.

How to Use Carton Sealing Tape

Carton sealing tape is fast and convenient to use. It is among the simplest packaging materials, but you must handle it appropriately because it can make a quite mess with a lot of tape wasted if you are not careful. Here are some tips below on using carton sealing tape to guarantee you get the most from it.

- Be sure it is indeed a carton packaging tape that you are using, not cellophane tape, craft tape, and paper masking tape.

- Carton sealing tapes are structured for sealing cartons with durable and long-lasting adhesion and are made from strong, bonded components. This strong adhesion ensures the tape will not peel off during delivery or storage nor will your parcel pop open to avoid disastrous consequences.

- Always be sure you are using the right adhesion tape for the job.

- In most cases, the carton should be applied using a tape dispenser. Not only does it make your packaging a lot easier and faster, but it also guarantees the tape has been appropriately applied, not producing any crinkles or tape sticking to itself. In addition, the tape dispenser’s pressure supports the tight sealing process directly to the carton box or surface.

How to Use Carton Sealing Tape Dispenser

Do you know what makes your packing and sealing efforts become easier, no matter what kind of carton sealing tape you are using? That is right, tape dispensers! They will help you pack customers’ orders easier and faster and even help you save tape, which is relative to saving money, time, and headaches.

Hand tape dispensers, also known as hand tape guns, are manually powered plastic cartridges since hands operate them and let you dictate just how much tape you want to apply before cutting them. They are simple tools that can be utilized by anyone handling high-volume carton packing projects, whether he is an employee in a warehouse or a family member packing up their home stuff. These tape dispensers are best used with carton sealing or cold-temperature tape because of their ease of application. Still, there are also dispensers made explicitly for applying the strapping tape.

Although carton sealing tape can be applied manually, just pulling it from the roll and then cutting it to the necessary length measurement makes it easy for the tape to twist and tangle. This is why it is essential for users to handle the tactile pistol-grop grip properly and apply the tape directly to the target surface. Tape dispensers and tape guns are commonly used tools to avoid wastage and ensure a smooth stick.

Here is a step-by-step guide on how to load and utilize a hand tape gun correctly:

- Fix the tape onto the wheel, ensuring it is precisely aligned with the carton box.

To manually operate, first, load your preferred tape roll onto the dispenser reel. Make sure that the tape fits snugly over the reel and stays in place. Also, you will have to ensure that the sticky side of the tape is facing downwards because this is how the tape will be dispensed to stick to the surface you are sealing.

- Extend the end of the tape to the cutting edge.

Extend the tape end at the edge part by threading it firmly through a dispensing slot underneath the cutting mechanism. Be sure that the tape is smooth and has not twisted or formed air bubbles

Once the tape dispenser is loaded, feed the starting part of the tape reel into the dispenser. Take the sticky end and pull this through the narrow dispensing slit. This will be a thin channel that leads at the front of the dispenser and to the cutting teeth, where the tape is fed through. Also, you may notice a lever clip present in the tool. You just need to pull it down to secure the adhesive tape in place.

- If the tape dispenser gun showcases a pressure-adjusting handle, utilize that to make sure the tape is ready for use.

Several tape dispensers feature a small adjustable screw in the center of the reel, which will allow the user to adjust the tightness and resistance of the reel. So be sure this is adjusted as needed to enable the tape to spin freely in the dispenser with some resistance.

- Press the tape to the box or package and pull along the surface

Once the adhesive tape is being fed through, you are ready to seal your first carton box and set up the dispenser for continuous use. Make sure the surfaces you want to tape are clean, meaning they are free from dirt and dust. After that, all you have to do is stick the end of the tape to the surface where you prefer the tape to begin. Then, simply pull the pistol grip along the length of the area to be taped. The adhesive tape should run off the reel and provide you with a nice, clean, straight seal.

- Cut the tape.

Simply tilt the pistol grip handle towards the surface to cut and finish, and be sure to do it front first. This will engage the cutting teeth across the adhesive tape, which will slice the tape and leave the next segment of tape ready to stick on the front of the reel.

On a side note, most big warehouses use tape dispensing machines instead, and they are deployed on automated packaging lines for high-volume professional use, often with special low-noise tape.

Conclusion

In a nutshell, it is essential to know which kind of carton sealing tape you need to use for your packaging needs so that time, money, and effort will not be wasted. More often than not, the adhesive tape is being blamed when carton packaging fails.

However, keep in mind that the combination of the tape, carton, the application method, and the condition of the environment are also big factors. You may not be able to replace some of these conditions, but taking them into consideration next time you choose a carton sealing tape may help deliver better, more secure packaging.

Get Your Carton Sealing Tape Today!

Whatever carton sealing tape you select, Shosky security tape can assist you. We carry a broad selection of PSA packaging tapes for every possible application. If you are unsure of what you need, you can simply contact us for assistance. Reach us today!